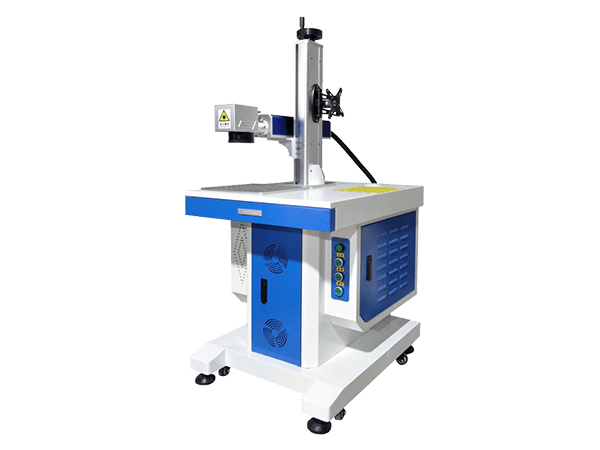

Fiber Laser Marking Machine

Professional Laser Marking Machine Manufacturer & Solution Configuration Expert in China

- Fast speed, high stability, and customizable solutions

- No installation and training required

- Competitive prices, accept global agents

Apply Our Best Quotation

Fiber laser marking machine uses the latest fiber technology to administer marks, engravings and abrading. Its laser beam technology is one of the best as it comes with the utmost stability and strength to deliver fast services.

Regardless of the nature of the services you need, all you have to do is regulate the set up of the fiber laser marking machine, and you are good to go. The technology can operate under any work environment for a long time.

The system does not need maintenance as the beam does not come into contact with the material being marked.

Alldo fiber laser machine can also mark on a wide array of materials including plastics metals and coated materials, different labeling processes are used depending on the material.

Alldo Tech Fiber Laser Marking Machine List

You can use it to mark any metal and non-metals, including glass and brass. It is ideal for both industrial and commercial applications. It has a marking speed that is two to three times faster than the other laser marking equipment.

Split fiber laser marking machine, power supply and laser split design can effectively avoid the machine from being burned. It utilizes a superior laser beam to deliver high-quality permanent marks.

Portable fiber laser marker delivers a marking depth of 50-80 microns, which is one of the best on the market. It has a vast marking space alongside a high marking speed to stay well ahead of your competitors.

The mini fiber laser marking machine is a compact size design that already has an inbuilt computer. It is designed to make permanent marks of logos, serial numbers, barcodes, etc on materials such as gold, silver, copper, iron, stainless steel and nonmetal surfaces.

The product lets you enjoy easy portability and marking or any metal and non-metallic materials, including glass and wood. The laser technology is highly table and does not get spoilt as it employs a non-contact marking technique.

The product comes in a compact size that makes it unbelievably easy to use. It does not consume a lot of power but does produce permanent marks on materials. It lets you enjoy easy features that are simple to apply.

Whether you are planning to use for office application or heavy industrial production, the desktop fiber laser marking machine has you covered. It marks at very high speed and does not develop glitches even after being used for many years.

This product enables online flight marking. It is highly reliable and delivers perfect markings on any material. It comes in a compact design and will not consume a lot of power. Its enhanced features make it pleasurable to apply in heavy industrial production.

This marking machine is easily portable. Lets you work anywhere and ensure that you meet the requirements of your clients. It adopts a silence operation; hence, you will enjoy its smooth work and speed. It employs the best laser beam technology.

Apply Our Best Quotation

How to choose a model?

Application Areas of Fiber Laser Marking Machine

Laser marking and engraving are the ideal solutions for endless applications, please choose your target area

Marking on Phone

Marking on Gear

Marking on Tools

Marking on Bearing

Marking on Automotive

Marking on Jewellery

Marking on Bolt & Nut

Marking on Knife

Marking on Hub

Marking on Equipment

Marking on Brake Disc

Marking on Connecting Rod

FAQ of Fiber Laser Marking Machine

Laser Engraving has become quite a necessity in the current industrial production. There are things to be marked, engraved, cut, cleaned, and many more. All these require an enhanced level of accuracy, something that can only be achieved with improved technologies such as the fiber lasers. Therefore, let us take a close look at some of the essential facts about laser engraving and delve deeper into them as we unearth every aspect of what needs to be known.

For the engraving industry, laser engraving has become a necessary process. It used by many companies around the world to enhance the production line. Note that laser engraving is a process that resembles many other laser processes. However, it involves a unique system that makes it stand out from the crowd.

If you are interested in learning more about laser engraving, then we are here to answer all questions that you might have about the same. This list contains most frequently asked questions about laser engraving. We have also compared it with other technologies to help bring our pint home.

- Can photos and images be engraved into a material using a fiber laser marking machine?

- Is it possible to engrave where my graphic will be marked?

- How does a fiber laser work?

- Is laser light a special wave?

- What is the physics behind lasers?

- How do we mark by fiber laser?

- What about the fiber Laser?

- Why are fiber lasers useful?

- How long does it take to operate Alldo fiber laser marking machine?

- How much does a fiber laser marking machine cost?

- How do I know the right watt of a laser machine to buy?

- What are some applications for fiber laser marking machine?

- What are the wavelengths for the laser marking machine?

- What can you do with a fiber laser?

- What are some of the industrial laser application processes?

- Why are the processes above useful?

- Can laser bed used in creating electronics?

- What materials can a fiber laser engrave?

- What laser training do we offer?

- What are the main types of fiber laser marking machine?

- Why should you consider fiber laser marking machines?

- What are the benefits of fiber laser marking machines?

- Can laser marking technology work with many materials?

- Does it come in a compact size?

- Can Alldo fiber laser marking machines work in extremely harsh environments?

- Are Alldo fiber laser marking machines easy to Integrate?

- What about performance?

- Does Alldo fiber laser marking machine have lower heat output?

- How does fiber laser marking machine work?

- Let’s take a recap of what a fiber laser is

- Why does this make fiber laser useful?

- What is fiber laser marking machine?

- What are the types of fiber laser marking machine?

- What are the common features of fiber laser marking machine?

- When was fiber laser marking machine introduced?

Q1: Can photos and images be engraved into a material using a fiber laser marking machine?

This is very easily possible. Many are the times when high-quality photos and images get engraved into materials by using laser marking technology. Both photos and images can be engraved into tech items like phones, signage, ID badges, gifts, and many more. It is important to mention that images and photos can get engraved into anything, but they are mostly engraved into metals and plastics.

The strength of the image and photo engraving depends on the quality of the source image. Therefore, it is advisable to consider engraving high-resolution images and photos. Go for something not less than 600 DPI.

Q2: Is it possible to engrave where my graphic will be marked?

Yes, it is possible to see the position in which your graphic will be positioned. If it happens that you are using crosshairs, you just need to move the Y-axis in the position where the lasering is supposed to be done. Now have the job placed on the plate to the crosshairs. You can see the dimension by moving the Y-axis slightly again. This will be displayed on your workpiece so that you can adjust it accordingly.

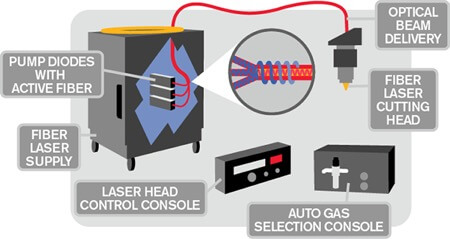

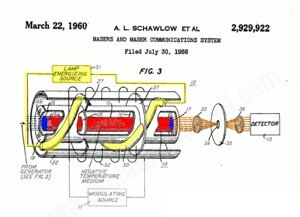

Q3: How does a fiber laser work?

Fiber laser uses the same principle as many other lasers, but there are a few things that make it stand out from the crowd. It is also kind of useful compared to many other systems, and we are about to discover how and why.

Q4: Is laser light a special wave?

Yes, it is one of the most special waves. Actually, if you spot that is spotted by a laser pointer onto a screen, you will learn that it looks quite amazing. There is a lot more to it that you might not see by just looking at it. Here are some of the unusual properties that are possessed by laser beams.

- A single colour and frequency

- Coherent, which means all waves go down and up at the same time

- The beam is almost straight (highly collimated)

The beams of the fiber laser will also go up and down at the same time and in the same color of light. During this time, all the photons get in step. When compared to light from a light bulb, these lights are of different colors and also flow in different directions. However, the ones from fiber laser move in a single direction accompanied by a high level of coordination. To some extent, this light can be focused, but you should know that there are many things that can be done with laser light, that you can’t do with the normal light.

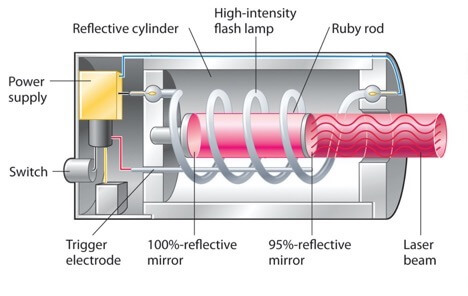

Q5: What is the physics behind lasers?

On a nutshell, the term laser means light amplification by the stimulated emission of radiation. We know that this might not sound clear enough, but let’s try to put it in a way that you can understand. When you hear light amplification, it means creating more of the same light. Just the same way an audio amplifier works uses the same sound to create more sound so that it sounds way louder. If we talk about stimulated emission, we are saying a word that is unique to scientists, but we could expound. It has something to do with the physical process that involves the creation of light. You need to know certain things about the atom before you are able to understand this fully.

There is something known as quantum mechanics, and they are only able to sit in particular orbits around atoms. It is the properties of the elements used that take part in the creation of the orbits, which means they can never be changed whatsoever. A good example is a gold, which has only one set of orbits. Oxygen and sodium also have the same. Each one is different in its own way; therefore, there are only a few of them that are relevant to what we are talking about right now.

In a situation where an electron is located in a higher orbit, which is also known as the excited state, it is always looking to turn into the ground state, which is a process known as decay. It needs to let go of some energy before it can accomplish this mission. This normally takes place when it gives up one photon, which can also be said emitting light.

To ensure that the electron gets to a higher state, the same process has to take place, but in reverse. It involves the absorption of a photon by an electron to get it to a higher level. Also, for the process to complete, in the photon, there has to be enough energy that is required to get that particular electron to a higher level. Nothing will happen if the photon does not have the right amount of energy to complete the process. As mentioned earlier, it is the type of element used that determines that amount of energy that is needed to move the electron to a higher level.

When the process is complete, and the electron has gotten to a higher state, it is kept there for a given period, and it will then decay to the ground state. Somehow, this is just a simple emission, not a stimulated emission, which means it is not what we would want to talk about.

If it happens that a photon of the same level of frequency passes by, it lures the electron to decay back into the ground at that particular time. When this happens, it produces another photon that looks exactly the same the one that passed by. Now, this is what is known as stimulated emission, and this is what we are looking to talk about.

The colour, also known and the frequency of the photon depend on the amount of energy that it is provided with. This implies that when the photons are served with similar amounts of energy, they will have the same colour.

The electron that gets elevated to a higher state and ends up dropping gain does not happen just naturally. Also, it does not take place often enough so that you can easily notice it. But here, we want to talk about how it happens so that you understand the entire process.

When the process is complete, and the electron has gotten to a higher state, it is kept there for a given period, and it will then decay to the ground state. Somehow, this is just a simple emission, not a stimulated emission, which means it is not what we would want to talk about.

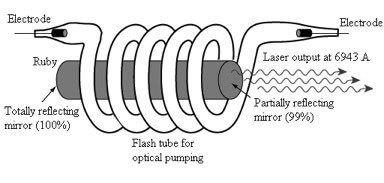

Q6: How do we mark by fiber laser?

To complete this process, we have two mirrors placed at either end of the material, known as ‘the laser medium.’ By doing this, we create what is known as a laser cavity. The mirrors ad in reflecting the lights back and forth and in every trip, more photons are created.

In the process, it is important to let out the fiber light so that it gets useful. This is the reason one of the two mirrors must not reflect anything. But it only lets out a tiny amount of light out. This is what we refer to the laser beam.

Q7: What about the fiber Laser?

Erbium-Doped Fiber Laser is one of the most common types of fiber laser, and it works pretty well. This is why we are going to use it to explain how the system works. Also, we are going to use a simple fiber laser that we have created from a silica glass. After forming it, we add it to smaller amounts of the rare-earth elements; Erbium. The tiny particles of Erbium are then mixed into the center of the fiber by the time it is made. This process that entails the addition of a small amount of rare elements is known as doping.

Maybe you need to know why we have decided to use the Erbium particles. Well, they are known to have atoms with good energy levels which are also quite useful. This energy is ideal to an extent that they can absorb photons with wavelength of up to 980nm, which then decays into meta-stable state which is equivalent to 150nm.

It is because of the fact above that we can choose to use a cheaper diode laser, as the pump source at 980nm and still get very high quality and even a very high power beam at 1550nm.

Our laser medium is found within the doped fiber, and it is the erbium atom. Also, the photons that get emitted are then confined within the fiber core. In order to craft our laser cavity, we use Brag Gratings.

Want to know what a Bragg Grating is? It is a part of glass that contains stripes in the section around the area that the refractive index has been changed. Every time the light finds its way across the boundary between the refractive indices, some of it gets reflected back. It is good to have enough stripes so that they grating gets to act like a perfect mirror.

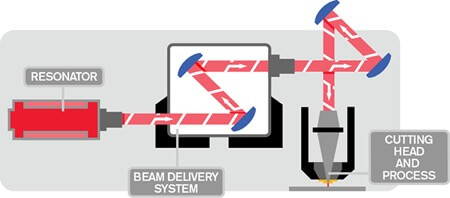

Q8: Why are fiber lasers useful?

The key reason why a fiber laser is useful is that it is stable compared to other lasers. By the time we are looking to deliver a laser beam, there always a need for a fiber laser to have it moved around safely. There is an alternative, which is to bounce it in between the mirrors. However, the mirrors have to be perfectly aligned to achieve that functionality. Having laser beam coupled into the fiber is a hard task since the core is a bit tiny and there is a need to have it finely adjusted.

Also, the normal lasers are unstable and quite sensitive, so they are not as reliable as the fiber laser. They lose the alignment at the slightest knock, so they are not reliable enough. Once the optics have lost the alignment, only a specialist can have them fixed.

The fiber laser is good because it generates the beam within the fiber, so you won’t need sensitive or complicated optics to have the beam delivered. Therefore, it is highly stable and using it is way easier.

The other reason we might prefer fiber laser is that it provides a beam whose quality is unbelievably high. Once the high-quality beam has been generated, it is confined within the core of the fiber, something that cannot be achieved by other lasers. This is because the beam is really straight; hence focusing it in the tiny hole is very easy. It is worth mentioning that the smaller the dot, the stronger the dot and the more effective the laser will be for cutting and engraving. This quality is required in all lasers, but only the fiber laser is able to provide it.

The next reason why fiber lasers are useful is because they can go up to high powers. At only 1 Watt, lasers get strong enough to harm the skin of the users. Compared to a kettle or toaster, this is not so strong of power, but imagine if it is focused on just one point. It is the same as feeling warm while basking in the sun, and then someone uses a lens to focus a beam from the same sun onto your skin.

The next reason they are the best is that they are easy to use and cooling them is also very easy. While other laser consumes a lot of power and is only able to convert a smaller percentage of the same (70-80%), fiber lasers consume very little power and convert almost the whole of it. This means that little power is consumed and most of it is focused so the fiber will not get hot and get spoilt. The beam quality is also very high.

Q9: How long does it take to operate Alldo fiber laser marking machine?

We specialize in making high-quality lasers, using the latest technology. As mentioned earlier, the thickness of the material that needs to be cut or engraved determines the time it takes to use the laser. Also, there are other things to consider, such as the volume of the gas and pressure that is supplied in the process. However, we leverage the latest technology to ensure that your work is done as fast as possible. Also, the fiber we make and sell come with the best features that are also easy to understand and take advantage of.

Q10: How much does a fiber laser marking machine cost?

There are many factors that come into consideration when trying to figure out the actual cost of fiber lasers. For instance, you might consider the features, application, amount of power consumed, size, and so on. That said, you might spend between $1,580 and $28,000 on a fiber laser marking machine.

The pricing and cost of fiber laser marking machines vary greatly depending n the power of laser, type, and the model. If you are looking to cut thick materials and metals, then you might have to get a higher watt laser. However, if you just want to cut things like clothes, you won’t have to spend a lot of money to invest in one.

Q11: How do I know the right watt of a laser machine to buy?

In case you are no sure the right plan to work with, or if you are looking to cut a wide range of products, then it is good not to rush with your purchasing plan. First, the fiber laser marking machine is quite strong and can cut almost anything. Though that is the case, you need to get the right watt. Again, the cost of the product you choose to get depends on the watt and many other factors.

For instance, if you have a wide range of products that need to be cut, it means some will be thick while some thin. Some will need more power. Fiber lasers that use higher watt to cut and engrave materials tend to cost a lot more. You will need around $10,000-$50,000 for a high-watt fiber laser marking machine. Other than the price of a high watt, you need also to consider the model of the products that you are buying.

If you are looking for a unique fiber laser marking machine, then you might need to go with a quote. Note that a special price will be set when you place a quote since there are special things that will be added to your products depending on how you would want it to function. You might need it to work with a given watt, or you might ask your expert to make it of a given size. All this will be considered together to know what you need to pay.

Before your experts start to work on your project, it is important that you discuss with them every aspect of it. Normally, clients who need custom fiber laser markers pay around $2,000 to $5,000 more. The price also varies among the manufacturing companies. If you have some knowledge, you can go ahead and build your own laser, but make sure that you are good enough to do it all on your own.

Q12: What are some applications for fiber laser marking machine?

We have covered a lot of fiber laser marking machine, but we feel that there is a lot more to mention about this awesome machine. Compared to other types of lasers, fiber laser machine has a light that is already coupled into the fiber, which is also quite flexible. Since the light is already available in the movable fiber, you can concentrate it easily on the movable focusing element. Did you know that fiber lasers can have very long heating regions that could go up to many kilometers long. This means that with them, you can get an amazing optical gain.

Due to the high surface area to volume ratio of the fiber, the fiber laser can support consistent output power. It also has a wave guarding system that protects it from the possible thermal distortion. As mentioned before, this is one of the coolest features that make it the ideal product that you should consider buying for the modern laser production. Have you used rod and or gas lasers, you will agree that fiber lasers are more compact than them. You can easily coil or bend a fiber laser so that you get to save some storage space. Also, fiber lasers have a lower cost of ownership. If you invest in a fiber laser marking machine, it means that you will not have to keep repairing and maintaining it.

This is possible since it does not get distorted easily due to high heat. Also, it is highly stable so that you won’t have to contact a technician to come fix it when you knock it accidentally.

You want to know the applications of a fiber laser marking machine? Their applications include material processing, which includes cutting, marking, and engraving, spectroscopy, directed energy weapons, telecommunications, and medicine. In the current time, fiber lasers are being used to make what is known as the high-performance surface-acoustic wave devices. Fiber laser is a name that can also be used to refer to the name of a machine tool that has a fiber resonator.

Q13: What are the wavelengths for the laser marking machine?

For many years, it has been known that at close-infrared wavelengths the metal reflectivity is a bit lower compared to longer emission wavelengths of the carbon dioxide gas lasers at 10.6 μm. The other benefit of employing short wavelength is that the divergence of the laser beam is more proportional to its wavelength but inversely proportional to the diameter of the beam that has been created. This has been illustrated in the equation indicated below.

Θ = λ/(πω)

Where λ = beam divergence, π = laser wavelength, and ω = beam waist.

From the equation, it can be deduced that shorter wavelengths permit shorter focus spots hence smaller surface features. Regardless of the limitations of the ability of focus, the longer wavelength or far-infrared gas laser will still retain a robust position in the entire marking industry. This is true because most marked materials like thin-film and paper and transparent polymers cannot absorb enough laser beam. However, the maximum absorption is required to help generate localized features on the surface, which are easily visible to the unaided human eye.

The lasers that are used to provide the near-infrared wavelengths like fiber lasers are ideal for marking a wide range of materials, including both non-metals and metals. In such cases, marks that can be seen by unaided human eye must be created by either ablating material and or crafting oxide layers on the surface. They could also be created by combining both of the techniques mentioned. The ablative marl might appear very clear to the unaided human eye, but when a high definition is used to examine it, one can easily see the evidence of small-scale.

From the explanation above, you can see that though started primitively, the fiber laser marking machine has gone through tremendous changes. The technology that it employs is exclusive, which has enabled it to stand out from the competition. If you are interested in getting the products, you can always get in touch with us. Through the years, we have worked with several clients, ensuring that we create a good relationship with them every time they choose to purchase from us. You could also be a part of our success story today.

Contact us Today:

With our technology and latest laser innovations, we ensure that your company attains the functionality and productivity that it deserves. Therefore, in case you are looking for the best fiber laser technology, you have all the reasons to get in touch with us. We have existed in the market for long enough. This means that we know what companies are looking for and with our creations; we integrate the best solutions for our clients. In case you want to know anything about Alldo Laser, we would be glad to be of help. Since our support operates 24/7, you can always shoot questions at any time that you feel convenient and our support team will reply almost immediately.

Better still, you can learn about our company and the products or services it provides by visiting our official website. Note that we are a team that works round the clock to ensure client satisfaction; this implies that our ears and eyes are always ready to feed on new information and improve our services or products accordingly. Thankfully, we are the best platform you can ever come across and you have found us.

Q14: What can you do with a fiber laser?

Since fiber lasers are highly flexible and easily adaptable and versatile, there are many applications in which they can be used. Due to the manner in which they work, they can be used for many applications because they let you take control of most of the application process. You get control of the length. The Duration, beam intensity, and heat output.

From the statement above, it would be true to say that with just one laser set up, you can do a lot of things. We mean a lot of things that might not be done by other laser machines. For this reason, it is safe to mention that fiber lasers are reliable for multiple reasons, some of which you might not be aware of until you consider investing in one.

Q15: What are some of the industrial laser application processes?

In this section, we are going to mention some of the best industrial applications that you could meet with our fiber lasers. While reading, you will notice some similarities and overlap among the applications. But we will be trying to keep the lines as clear as possible. If you go to our brief, you will learn why each application is unique and why we think they need to stand on their own.

- Laser Marking

You must have heard about laser marking. On a nutshell, it is the process in which a material is marked using a fiber laser or rather a laser marking material. The fiber laser, in this case, uses a beam to give you the desired mark. There is a very close similarity between laser marking and laser engraving. It is also similar to laser ablation. However, there is a difference and it is that with laser marking, the mark is only left on the surface.

- Laser Cutting

This is the process that is used to powerfully cut through a material. Traditionally, companies used cutting blades to get attain their cutting goals, but that was before the introduction of laser machines. The advantage in this case is that there is no contact with the material when using a fiber laser cutting machine. This implies that you will not need costly cutting discs for the replacement. The machine will also not encounter any downtime. Everything will be done perfectly, and you can use your machine as long as you wish because it will not get distorted.

- Laser Welding

Laser welding is one unique process and you can do it best with a fiber laser marking machine since it will not consume a lot of power. In this process, two materials are welded together under high temperatures. Note that they might be dissimilar materials as long as they are both metals and can be welded together. This means that you don’t have to weld two metals that have similar qualities. This is an application that is required in industrial applications in which a wide range of metals are being used to create products.

- Laser Drilling

This works in the same way as the laser cutting. But in this case, instead of cutting the material, we are drilling into it. You will not need the drilling tool to finish this process because you are looking for the best quality. You need a powerful laser beam to complete the process.

- Laser Engraving

Laser engraving is also more or less similar to laser marking. It all depends on the set up that you are using. In this case, the mark is done deeply so that it looks more like a deep cut. This one is more useful to jewelry industries.

- Laser Ablation

Laser ablation is also quite similar to laser engraving and laser marking since they are all completed in almost similar processes. However, in this case, we are trying to ensure that no mark is left behind. Our primary aim is to have the top surface melted so that we leave the surfaces below exposed to the eye.

- Additive Manufacturing

This is an essential process that is used in the 3D printing and needs to be done rather carefully. It is best done with the help of CAD software. All types of materials can be 3D-printed, depending on the level of the expertise that the users has. Fiber lasers have gained a lot of prominence in marking items, and they have features that make them useful in 3D printing. Reliable parts of metals, glasses, woods, ceramics, and many other materials can be manufactured really quick.

- Laser Cleaning

This process is very similar to ablation process and involves similar procedures. It also involves melting the surface to reveal what is left on the inside. In some cases, the procedure is used to cut into deeper surfaces so that the most inner layers are revealed. However, we major our focus on cleaning the material. Therefore, you need to cut depending on the location of the impurities you are looking to remove.

Q16: Why are the processes above useful?

From the list above, you can see that there is a handful application for which you could use the fiber laser. Why are the processes important, you ask? The applications above are important in the production industry as they help companies meet the expectations of their clients.

If you check our page, you will learn that we deal with a wide range of laser marking machines and that they work in different ways. Note that they can all be used for the applications mentioned above. What might vary is the manner in which they are used.

Are there Case Studies for The Applications of Fiber Lasers?

Now that you have learned various aspects of the fiber laser, we want to serve you with case studies to give you a glimpse of how the systems work in real life.

Use on Reflective Materials

One of the best features of our products is that they have been designed to work on reflective materials and you will not see any damage caused on the machine itself. If you have been in the industry for enough time, you will attest to the fact that this is one ting that other lasers can only struggle to achieve. Reflective materials will always try to reflect the laser beam back into the material. If your laser is not steady enough, it might not work well. However, fiber laser machine will not have any problem with such surfaces since we ensure that we harm them perfectly.

Our fiber lasers are carefully crafted to ensure that reflection of the laser beam does not give them any problem. This means that all the applications that we have discussed above can be done even on reflective materials. These materials are mostly aluminum, silver and other metals.

When you purchase our product, we ensure that we demonstrate you the processes so that you see what we mean. We also show you how detailed and intricate the processes can be during industrial application.

One of the most important applications of fiber lasers is the formation of traceable labels and barcodes. This is normally done either through laser engraving or the laser marking method. The industries such as medical sector and dentistry might not do much without this process. Fiber lasers are used to make hundreds of equipment that are used to achieve a lot of impressive results in both medical and dentistry sectors. It is one machine that can help you achieve incredible accuracy regardless of the application you are using it for.

It is the nature of the industries that make them need traceable barcodes and labels, and this is one of the ways that fiber lasers come in handy. Fiber lasers can give you marks that are so easy to read.

Scientific Research

In many ways, fiber lasers have helped to conduct important medical research, and they are being used in all parts of the world for the same reason. The system ensures that scientists get the best efficiency and accuracy. Just like many other industries, scientists are already looking even better ways in which they can utilize the benefits of fiber laser machines.

There is a good example. There was a scientific research that was concluded, and it was done by just looking at the laser gun. This is one of the things that would only see in star war. In this field, there have been a lot of improvements, courtesy of fiber laser marking machine.

The other uses of the fiber laser machines in the field of medicine and dentistry include spectroscopy. This is the field of science that is concerned with measuring the spectra that is

Q17: Can laser bed used in creating electronics?

Yes, the fiber laser technology has been for a long time used to produce a lot of electronics. Some of the industries that we work on include semi-conductor, battery, and many more. In these industries, the fiber lasers are used for many reasons. However, the benefits that are brought by the fiber lasers remain similar across each one of them. In simple terms, there are many ways in which they are interlinked.

The one application takes advantage of the fact that fiber lasers can work on extremely tiny materials, which is why it comes in handy in many electronic industries. This is a huge plus owing to the fact that the electronic industry keeps getting smaller and smaller. As time goes, their demand for the fiber laser technology keeps getting bigger. Fiber lasers can work with smaller objects without causing damage to their surrounding objects. They are mostly used where a high level of accuracy is needed, and the material to be worked on extremely small.

The other reason they are useful in electronics is that in this field, most metals have different properties, which means they need to be worked on carefully. If you are not looking to employ a different setting and system for each one of them, with fiber laser, you get to achieve everything under one roof. Now this explains why welding, that we mentioned in the list of applications is way more important.

If you have worked with a fiber laser machine before, then you will know that it is one of the best solutions for a wide range of materials like metals, rocks, ceramics, plastics, silicon, and many more. Therefore, we would be right to say that yes, fiber lasers are the best for drilling rocks. It is good for drilling rocks, and it is already being used for this purpose.

If you look above, you will see that we have mentioned this application already. But if you want it right here, yes, fiber laser can be used in 3D printing. It would be wrong of you to think that 3D printing is a new technology. This is one thing that has always been there. However, it seems to be a bit common these days. But that does mean fiber lasers cannot do it. After all, this is a system that can be used on any material, and you have seen houses that have been 3D-printed.

Q18: What materials can a fiber laser engrave?

Fiber laser is a carefully fabricated technology that can cut, mark and engrave any material without any problem. Since its introduction, it has been used by almost all industries to achieve accuracy and the quality that is demanded by their clients. Therefore, if you are a company looking for something that would help you achieves the bottom line, then you are talking about fiber laser technology.

Q19: What laser training do we offer?

We are a team of experts who are looking to ensure that you get the most reliable engraving experience. Therefore, we have come up with the best training in all possible applications for which you might use our products. By taking a closer look on our website, you will see that we have been in existence for a long time, and we ensure that when you purchase our product, we support you for at least 12 months.

During this time, we work closely with our clients to answer all the questions that they might have about our products or services. Our training covers things like assembling, using, and fixing minor glitches that you might encounter while using our products. However, our products are fabricated to ensure that you don’t experience any difficulty while using them in your company.

Alldo Laser is always looking to provide you with the best products at affordable process. This is why we are the best company that you will ever come across. If you have never check out our website, makes sure to see our products and the amazing features that they have. Also, our team of experts is always looking to hear from you. It works 24/7, which is why you can always contact us at any time of the day.

Better still, on our website; there are contacts that you could use to speak directly to our representatives. Also, note that all our products come with a one-year warranty. We believe that you deserve the best, and if you are not happy with our product, within a period of 12 months, you can return it for a full refund. But we believe that all your solutions shall be possible if you choose to purchase from us.

Q20: What are the main types of fiber laser marking machine?

Depending on the type and nature of the work you want to be done, you can get the right laser marking machine. Note that with the current technology, you can get a different quality of work, and it all depends on the type of laser marking machine that you choose to employ. For your own convenience, here are the different types of laser marking machines that you can choose to use depending on the nature of your project.

- Stationary Fiber Laser Marking Equipment

- Split Fiber Laser Marking Machine

- Portable Fiber Laser Marking Machine

- Handheld Fiber Laser Marking Machine

- Desktop Fiber Laser Marking Machine

- Enclosure Fiber Laser Marking Machine

- Flying Fiber Laser Marking Machine

- Swing Arm Fiber Laser Marking Machine

From the list above, it is easy to tell that with the help of technology, it is possible to get a wide variety of jobs done. However, if you have a variety of projects that need to be done, you will have to budget for more than one type of fiber laser marking machine.

Q21: Why should you consider fiber laser marking machines?

The first thing you have to know is that this is not the only type of laser marking machine on the market. You also need to have in mind that it stands out of the competition for essential reasons. Actually, a careful look into the market will reveal that the gas lasers that leverage carbon dioxide and helium-neon are a little common. But this is because they have been in existence for a more extended period compared to the fiber laser marking machines.

It is worth knowing that fiber laser marking machines are the beasts on the current market; but they come with both ups and downs. However, to some extent, it seems like the fiber laser marking machines have many advantages compared to the other laser marking machines. It is also the newest technology compared to other technologies in laser marking, which means that they take part in essential functions.

In a few previous decades, fiber laser marking machines have helped solve many problems, and they have gained a lot of popularity in different parts of the market.

It is worth noting that there is one benefit that has helped it stand out of the competition, and we are about to discuss it in the later parts of this chapter.

Fiber laser marking machines have been used in the telecommunication, and they perform an integral duty in the phones that we now use every day. They also play an important role in the transport, and even in the medical industry that has enhanced the lifespan of humans in almost all parts of the world.

The things that have been mentioned above covers the most important facts about fiber laser marking machines, and why we need them so much. The other fact is that they can be used across many industries and that they can adapt very fast and easily. Therefore, they can be used for a wide range of options.

Fiber laser marking machines can be used for a wide range of reason from making machines to perfecting diamonds and also assisting with critical medical surgeries. Fiber lasers are presently the most critical adaptable machines that we have around. They can be modified to offer a wide range of solutions.

Regardless of the industry that you serve in, you must have a problem or two that can only be best solved by the fiber laser marking machines, or the laser technology itself.

Q22: What are the benefits of fiber laser marking machines?

Versatility is an important thing across industries. However, as mentioned in other parts of the section, fiber laser marking machines are important in different ways and can be used to complete different types of projects. This is because once you have accepted to embrace them, you get a lot of control over whichever thing you are working on.

The main industries that are served by fiber laser marking machines include:

- Dental

- Medical

- Printing

- Solar

- Electronics

- Sensors

- Automotive

- Sensors

- Jewellery

- Scientific

- Aero scope

Now let us talk a little bit about the level of control that you get from embracing the fiber laser marking machines.

With the laser marking machine, you are given the power when it gets to intensity, duration, beam length, and the heat output, therefore, you have the best opportunity to adjust the beam to match the situation that you are dealing with.

With fiber laser marking beams that we deal in, you can make the most precise cuts and even perform the most accurate surgeries. This has been made possible due to the fact that the technology leveraged by the fiber laser marking machines is focused on accuracy and nothing else. Though most of the accuracy and quality rests on the hands of the user, you will learn that the laser marking is an amazing technology to spice it up for you.

Q23: Can laser marking technology work with many materials?

The other advantage of laser marking technology is that it can work with many types of materials. The products that we deal in can work with silicon, ceramics, polymers, gemstones, metals, and precious metals.

Also, you will learn that the fiber laser marking technology can work with reflective metals pretty well compared to other laser marking technologies. Note that in most instances that you get seamless results with laser marking technology; other technologies will do nothing but struggle to issue you with quality results.

The other thing is that reflective metals tend to reflect anything that is directed at them to the point of origin hence destroying the laser marking machine, but that is not what you get from the laser marking machines. If you employ the SPI fiber lasers, you will not at any point report the same problem mentioned above.

Q24: Does it come in a compact size?

If you have used other technologies before, you will learn that fiber lasers are a little smaller in size and that they are relatively easier to use. This means that they are a lot easier to install in other machines and can also be transported easily. They are also relatively economical when it comes to the storage space in the workplace.

Their compact size also makes them useful when you have a lot of things to do in the workplace. For instance, if you have a small company, but you have a lot of things to do at the same time, you will easily find enough space for the fiber laser marking machine within the office layout.

Q25: Can Alldo fiber laser marking machines work in extremely harsh environments?

Fiber laser marking machines are the best for the companies that are located in harsh and less hospitable areas. This is why they are useful for any company in any part of the world.

Q26: Are Alldo fiber laser marking machines easy to Integrate?

In our company, we ensure that you get a complete set up of the fiber laser marking machine. This means that we take care of every aspect of the technology so that once you get it, you can start using it right away. Also, you are free to integrate the machine with other equipment that it can work with.

Note that the fiber laser marking machines that we deal with have been naturally programmed to fit in any laser-based system or appliance, again taking note of their extreme level of versatility.

Q27: What about performance?

In the modern-day, companies tend to select technologies that can provide them with the highest level of performance. This makes sense since every day, the level of competition keeps getting high and complicated. It is through our careful study of the current market trends that we supply the most reliable fiber laser marking machines.

With fiber lasers, you get the type of quality that cannot be provided by other technologies. Also, you get it without spending a lot of money on it. We care about the nature of functionality that you get with our technology, which is why we also take you through the shopping process. This is the one thing that has helped our company to stand out from the competition.

If you are looking for the tasks to be completed at quicker rates, we are here to make that happen for you. With our innovation, you get this with the lowest power consumption. Note that the less the power consumed, the less the expenses incurred by the company, and we care for all that.

Q28: Does Alldo fiber laser marking machine have lower heat output?

Our fiber lasers work with the latest cooling systems, and that is an important feature being that most companies waste lots of money since they use technologies that consume a lot of power due to heat consumption.

The amount of heat is kept low, and the available levels are distributed evenly throughout the system.

This means that the heat that comes from our systems are kept low at all times. This ensures that there are limited chances of damage. In the long run, you will not have to spend a lot of money on maintenance.

Q29: How does fiber laser marking machine work?

If you are working in the modern industry, it is essential to understand how fiber laser technology works. We have covered every aspect of it in this piece. Even if you have been working in the industry for some time, still, you can use this knowledge to augment your existing knowledge and skills.

Q30: Let’s take a recap of what a fiber laser is

A fiber laser is a laser in which an optical fiber is the most active medium that is used. The fiber that is used has been dipped in rare earth elements such as thulium, neodymium, Erbium, holmium, ytterbium, or dysprosium. There is no need for you to worry about the actual rare element that is being used. What you need to understand is the fact that fiber is the one that forms the basis of this system.

This implies that there is a difference between this laser and other lasers like carbon dioxide and gas laser. Note that in the current market, fiber laser is the newest and is doing great in terms of quality provision. According to initial cost and the features with which they come, fiber lasers are the best in every sense of the word.

As mentioned in the earlier sections of this piece, in fiber lasers, fiber is the medium that is being used, and it is dipped in rare earth elements. Though any rare earth element can be used, you will notice that most of them use Erbium. The one reason this is done is that with the rare earth elements, you get extremely high energy levels that are needed to perform certain essential duties in the industry.

A good example is that by dipping fiber in Erbium, there is a process that takes place. It involves the decay of photons with a wavelength of 980nm due to the high energy levels. This simply means that it is possible to use a laser pump source of 980nm and still end up with the best quality, a high-power laser beam of at least 1550nm and high energy.

It is the Erbium atom that takes part as the laser medium in the dipped fiber. In the process, the photons that are emitted are retained within the core, which is the fiber. It is also necessary to craft the cavity on which the photons are retained, and it is done through the addition of Fiber Bragg Grating.

If you want to know what Fiber Bragg Grating is, it is a section of glass with some stripes on the inside. This is the area in which the refractive index gets altered. In any moment that light passes through the boundary that is between one refractive index and another, a small amount of light gets refracted back. It is the Bragg Grating that makes the fiber to behave like a mirror in the fiber laser technology.

The pump laser is also get focused into cladding that is found in around the fiber core since the fiber core is rather too small. Hence, there is no way a low-quality diode can be focused into it. The laser is bounced in the inside by having the laser pumped into the cladding that is found around the core. Every moment the laser is pumped into the core, more of the light get absorbed by the core.

Q31: Why does this make fiber laser useful?

Though there is a lot of science mentioned above, we thought that it is important to outline the advantages of the manner in which the fiber laser technology works. One key advantage that fiber laser technology provides to the users is that it is extremely stable.

This is important since other lasers tend to be highly sensitive to movement. This implies that even if they are knocked slightly, the whole laser alignment gets lost. If the optics get misaligned, then you will have to invite a technician to get the laser working again. However, the fiber laser marking machine creates and uses its own beam within the inside of the fiber. Therefore, you will not need the optics, which can be sensitive, to get it working right.

The other advantage as a result of how the fiber laser marking machine is that the beam quality is extremely high. This is possible since the beam produced remains within the core of the fiber. This way, it creates and maintains a straight beam that can easily get ultra-focused. Also, the dot made by the fiber laser marking machine can be kept extremely small, which is a proper functionality for applications like laser cutting.

Both the quality of the entire work and the level of power delivered by the fiber laser are kept at high. Note that as technology keeps improving, so is the power that is delivered by the fiber laser marking machine. Therefore, with fiber laser, you can easily cut metals of any kind and thickness. It is a technology that has really improved the quality of work that is done by companies.

The other benefit of fiber laser technology is that despite the high-power intensity and output, cooling them is very easy. This makes them highly efficient since they can be used for longer durations without getting degraded by high intensity and power output.

With many other lasers, you will learn that most of them consume power, but they only change a small amount of the same into a laser. Fiber laser, on the other hand, consume energy and then converts between 70-80% of it into a laser. This is an indication that you will not waste any power when using this technology.

If you are looking for efficiency, fiber laser technology converts almost all the power it receives into a laser. This also indicates that very little amount of the same power is being converted into heat energy. Now you can see why the systems are very easy to control.

Note that while the length of the fiber is really long, the little heat energy that has been formed is uniformly distributed through it. This implies that no particular part of the fiber, of the entire system that will feel too hot. This is a huge advantage since you will not have to fix any part of the system regularly as in the case with other technologies.

On the final advantage of the manner in which the fiber laser works, it functions without emitting too much noise. You will not have to spend lots of money to cater to maintenance cost. Ideally, you will not have to fit the system anymore since we leverage the fit and forget technology. Therefore, if you have a project to take care of, there is no stopping once you get started.

However, in case you might need to have something fix, its cost is around 505 less compared to other lasers.

Q32: What is fiber laser marking machine?

Fiber laser marking machine is the most common in the current market. It has a vast range of functions, which is why most industries prefer using it. It is used to label products where information about a given product should be shared to the consumers. Such details include the price of the products, size, color, features and many others. In the current market, there is a plethora of marking machines. However, in this piece, we are looking to delve into the fiber laser marking machine. It is worth noting that before you choose to buy a laser marking machine, you review their features and functionality and if they will meet your operational needs.

Though there are extensive types of marking devices, (and we are not referring to laser marking machine prices) fiber laser marking machine is the most common one. You are most likely to find it in many industries. Thanks to its straightforward features and affordability. It is used in medicine to graduate medical devices that require sterilization. This laser marker puts marks that cannot be erased by natural elements. The marks also can withstand high temperatures, which are known to rid marks that have been placed on items.

The device also helps in jeweler engraving because the units used are highly precise. It is great for personalizing jewelers and any special item that you might have.

If you have a need to cut out names and create monograms, fiber laser marking machine comes in handy. It is possible to make use of the units to create unique design cutouts.

Though we will cover this in subsequent chapters, it is still accurate to mention that fiber laser marking machine comes with numerous benefits. One of the benefits is that it is unbelievably easy to use. Once you have acquired your laser marker from us, you will not have to go through rigorous training before you can use it. Just in a few hours, you can go through the manual that they come with, and you will understand how it works.

The fact that the units are easy to maintain helps you save lots of money. This is because there will be no need for you to hire experts regularly to check what is going on. Even if you don’t have a lot of space, they come in small sizes to make storage easier. There are companies that operate remotely, and they might want to move from place to place, the laser marker is not bulky; hence carrying it around is easy.

Q33: What are the types of fiber laser marking machine?

The modern power lasers are powered by powerful, multimode diode bars of single-emitter diode. Every single mode core measure 5 to 12 µm in diameter. The fiber used contains inner-single mode core that is doped with the right rare-earth ions like neodymium, ytterbium, erbium, and thulium.

Also, the laser contains a coil of ideal double-clad doped fiber, a pump source, and two reflectors. In some cases, the source is a single-emitter diode, or s pump fiber laser, or diode bars. Now let us look into different types of fiber laser marking machines.

- Pumping Fiber lasers

- Single-mode fiber lasers

- Multimode kilowatt fiber lasers

- QCW fiber lasers

The fiber lasers listed above are the ones that are mostly used in many industries. They are used in industries for sintering, cutting, welding, drilling, scribing, marking, and heat treating.

Q34: What are the common features of fiber laser marking machine?

You can check out our official website for more information about the parameters of fiber laser marking machines that we deal with.

Now let’s look at the marking machine application. If you are looking for the perfect laser marking machine for metal, then this one might be of interest. It works for almost all kinds of metal while maintaining the optimal speed. It even works for the non-metal items, which means you could use it for all your applications. Gold, silver, aluminum, copper, alloy, stainless steel, and plastic can all be marked by this revolutionary laser marker.

It works for a wide range of industries including auto parts, keyboards, cell phone, jeweler, kitchenware, stainless steel, glasses, knives, electric appliances, communication apparatus, sanitary equipment, buckles, and the list goes on. You can use it for decorative maps, engraving codes, serial numbers, LOGO, and many more.

From a reliable manufacturer, the product comes with a one-year warranty for the entire machine; this is one of the many features that make fiber laser marking machine to stand out from the competition. If you get the product from us, we provide you with 24-hour lifetime support. This means you can ask us any question about the products at any time of the day, and our support will be there to listen and solve your issues.

Q35: When was fiber laser marking machine introduced?

In the past few years, there has been an exponential growth in the laser marking industry as a whole. Also, the products are available from many dealers in almost all parts of the world. However, if you want to get a high-quality product, it is advisable that you purchase it from a reputable dealer. Today, all industries demand traceability due to an ever-increasing number of products and components. In that regard, the laser marking machine has bridged that gap since it is fast, efficient, easy to use, and less pricey. Compared to the conventional marking techniques, the fiber laser marking machine can do a great job and is highly flexible.

Though there are different laser types that also come with varying laser wavelength, the fiber laser marking machine has manifested a dramatic increase, and you are most likely to find it in almost all companies since they need efficiency that only it can provide. If you check carefully, you will notice that almost every marking system has a fiber laser powered make in their range. This is an indication of great job and quality with which it provides the users.

The tremendous benefits of this machine are known by all industries and are clearly documented. However, in this article, we have included many other things that we believe are worth knowing and have not been published by the rest.

In 1998, there was limited use of low-power continuous-wave fiber lasers. They were mainly used to mark integrated circuits. A few years later, the nanosecond units were introduced, and they had a greater capacity to help with a wide range of applications. It was this time that marked the revolution of the fiber laser marking machine that we have today. Today, we see it everywhere, but did you know that it keeps getting better as the demand continues to get dynamic? In 2011, it was reported that the gross fiber laser marking machine alone rose to 48%, which is a huge growth compared to what used to be there before. Also, it is worth mentioning that when it comes to engraving segment fiber lasers indicated an overall growth of 34% compared to its closest competitor; Diode Pumped Solid State (DPSS) laser. This one only grew by 4% in the previous year, now you can see how the laser marker has grown so fast since its debut, and it still keeps doing well.

For deeper faster engraving, the fiber laser has encountered a lot of technological advancement so that it services the needs of clients, which also keep getting complicated. That fact that it has gone to 700mm/s is a clear indication that beast is way too determined to rule the marking industry for the longest tie possible. In 2011, at least 10,000 fiber laser marking machine units were sold in different parts of the world, but we are in 2019 and you can only how big it has already gone.

Get In Touch