We Know How

Jewelry laser engraving machines make personalised and creative permanent markings on jewelry such as gold and sterling silver. The jewelry laser engraving machine engraves with a high speed laser beam focusing on a specific point on the jewelry and makes permanent engraving. This computer controlled process is highly effective and completely flawless.

It can also be applied to the cutting of gold plates with a thickness ranging from 0-1mm.

The engraving process is damage free as the laser does not have a physical contact with your jewelry. Identification texts, serial numbers, logo, individualised images, can all be engraved on jewelry to make them stand out. The jewelry laser engraving machine is used to engrave on products such as rings, bracelets, watches, pendants, medallions.

Jewelry businesses are now able to attain the highest standards through laser engraving machines for gold jewelry, but they are also recognizing profits and keeping costs down.

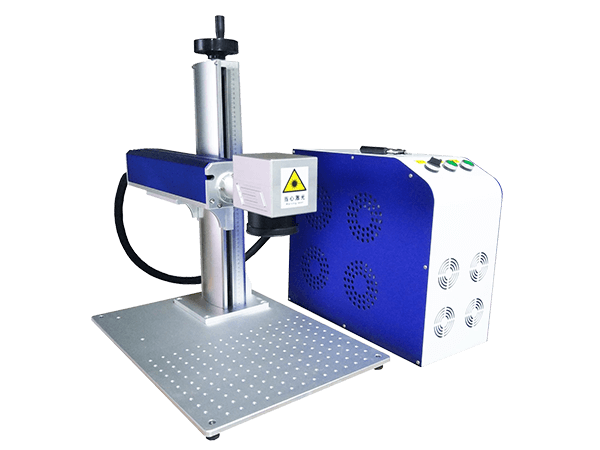

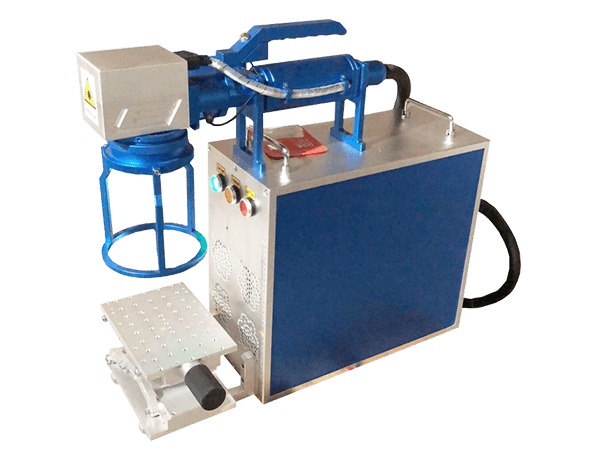

What Machines You Can Choose

Choose the Top Technology for Jewelry Marking and Engraving

High Speed & Stability

Achieving a marking speed of 8000mm per second, the marking will not freeze, and its stability.

Competitive Prices

Alldo Tech is a manufacturer with a competitive price and accepts worldwide agents.

Custom Different Depth

The standard equipment configuration can achieve a marking depth of 0.6mm.

No Maintenance Costs

It has no consumables, the parts have a long service life and require almost no maintenance.

Laser engraving techniques have by far become the most popular method for jewelry engraving today. The best reasons for choosing our custom laser engraver for your jewelry is that it provides flexibility, permanence, precision, affordability and quality.

The lower power consumption , long life (100,000 working hours) and air cooling system that makes our jewelry laser engraver your best choice. We provide your guide and instructions on how to make your engraver work, if you are a first time user.

Feedback from Our Clients

The jewelry etching machine is really efficient and offers precise results. Now I can explore my hobby of engraving.

For damage free jewelry engraving, Alldo Tech fiber laser engraver is the one for you.

Instructions were easy to understand. And the software is sophisticated. Very light , easy to take .It is a cool laser engraver on jewelry. Love it!

I was able to do laser engraving on rings and the etching was good.

The small jewelry engraving machine offers the most economical and environmentally safe.

FAQs About Jewelry Laser Engraving Machine

Jewelry Laser Engraving and Marking Machine

Ultimate Buying Guide

Contents//

CHAPTER 1. HISTORY OF JEWELRY ENGRAVING AND MARKING

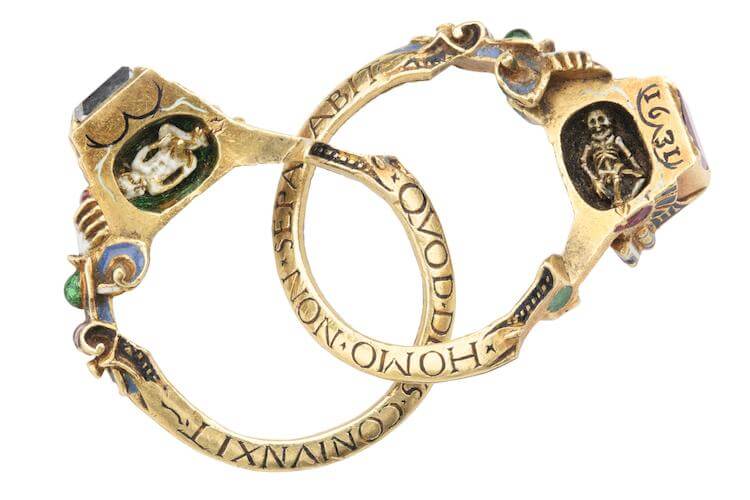

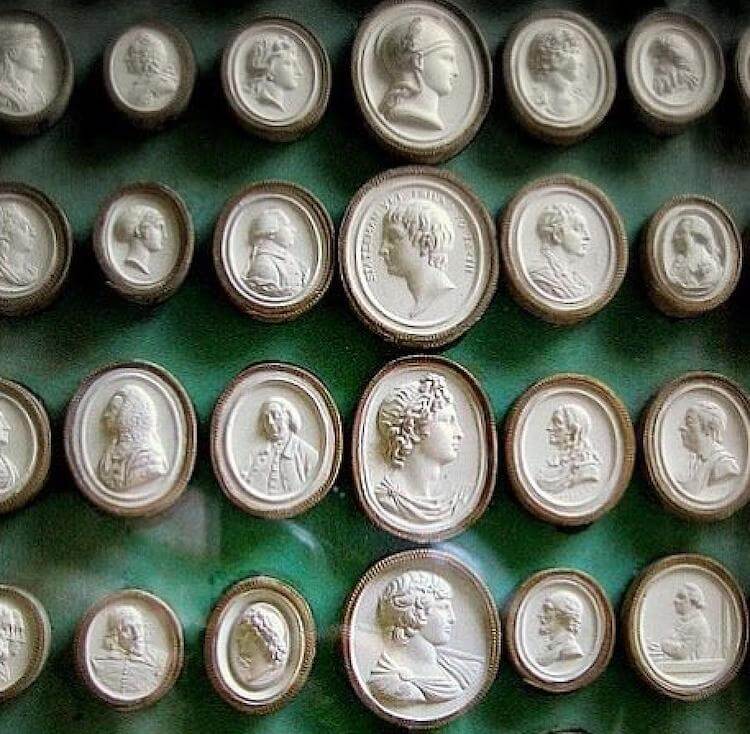

Jewelry engraving and marking dates back to the first centuries BC in Egypt and Rome where gemstones called “cameos” have been discovered. Jewelry engravings back then were used to signify wealth by people. Ancient engravers during 3000BC engraved seals into jewelry for wealthy people.

Engraving during this time was done by hand, handheld tools like gravers were used to carefully remove small amounts of metals to create design on jewelry. Hand engravers are limited by the size of their surface and imagination.

Jewelry engraving involves making design prints or impressions on jewelry using several techniques including cutting, acid corrosion with different tools.

1.1. EARLY JEWELRY ENGRAVING

In ancient times engravers manually used a burin which is a hardened steel tool to cut designs into jewelry surfaces mostly made of copper. More modern methods of hand engraving involve the use of engravers to engrave different metals like gold, sterling silver, and steel. They used small special chisels known as “gravers” and were used along with small hammers to assist the work. Gravers are tiny and very sharp handheld chisels that result in deep and bright finishing on jewelry.

Jewelry engraving machines which require less human perfection are also used, and an example is a pantographic system which can be used for lettering or making inscriptions. Pantographs come in various kinds, and some can be used to make engravings easily on the inside parts of jewelry such as rings and other items like lockets and medals.

1.2. 21ST CENTURY JEWELRY ENGRAVING MACHINE

Jewelry laser engraving serves a purpose ranging from creating personal bonds and keeping history to making lasting memories and expressions of love. In recent times, the need for engraving metallic ornaments like gold jewelry has increased. A major reason for this is that people can personalize jewelry with their names marked on it.

Modern jewelry laser engravers can also be used to make designs such as: texts or images on gold and silver jewelry, for example on pendants or on the inside parts of engagement or wedding rings. The software translates the texts or images from the computer system into digital signals, and the jewelry laser engraving machine responds by making these designs with lasers. Jewelry laser engraving machines are highly proven as it has shown its strength economically and regarding quality by its precision and repeatability.

With the introduction of the personal computers in the late 1970s, personalised jewelry engraving moved to a new landscape. The computerised jewelry laser engraving is faster and more precise than either hand engraving or the pantograph technique could ever provide.

1.3. JEWELRY SUITABLE FOR ENGRAVING

Engraving is a simple and quick process. Engraving is the action of marring the surface of any material, especially metals, in order to create a design or mark on the object. Unlike hand engraving tools, jewelry laser engravers can engrave with you having a feel of the engraved surface. Engraving is permanent and precise.

Semi-precious stones and gemstones can be engraved using a jewelry laser engraver. The jewelry laser engraver is so precise that you will get the exact design that you want on your jewelry without worry. Also, there are some gems, such as diamonds, that can only be engraved using jewelry laser engraving. Many jewelers use beautiful coloured glass beads to create glass pendants for necklaces. Other jewelries that can be engraved include:

Wedding rings: Many people prefer their wedding rings engraved with the names of their spouse or the date of marriage. Laser engraving inside a ring is a quite common process.

Bands: Men’s bands are very fashionable and trendy presently. Some men’s bands are engraved on the outside with tribal patterns, logos, flames or pets.

Dog Tags: Dog tags are oftentimes made with silver. Names and initials can be engraved on dog tags or one could opt for an image or short quote.

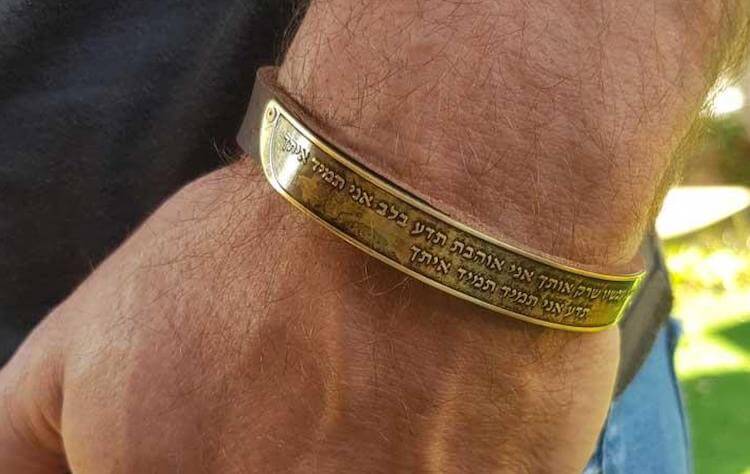

ID Bracelets: ID bracelet has a small blank plate usually made of gold, silver, steel, platinum, titanium, which is attached to a sleek chain or any piece of leather. Name, initials, or any meaningful texts can be engraved on the blank plate, thereby giving your jewelry a personalised touch.

Watches: Watches are often engraved when given as gifts. Engraving on a personal watch is also possible. Aside from adding a personalised touch to your watch jewelry, your watch can easily be traced if misplaced.

Pendants, bracelets and lockets: Images and texts are engraved on pendants, bracelets and lockets for style and beautification.

Keyholders: Keyholders made of sterling silver can be engraved with a silver engraving machine.

CHAPTER 2. TECHNIQUES AND TOOLS FOR ENGRAVING JEWELRY

The jewelry laser engraving machine uses a high powered laser beam to change the surface of the material that is being engraved. The heat from the jewelry laser engraver bonds the marking agent to the metal, this, however results in a permanent mark. The jewelry laser engraving techniques include:

- Laser Evaporation: Laser evaporation involves creating high heat when marking that causes the material to vaporize from the surface. Damage is reduced in the material surface when this method is used.

- Laser Etching and Melting: Etching or foaming involves a part of the material melting with the help of the laser, then, the melted material surface cools to form the engraved shape. The pulse of the beam velocity determines the engraved shape.

- Laser Welding: Laser welding process involves using another material along with the original material. The jewelry laser machine helps the external material bond with the base material.

- Laser coat and Mask: In this method, the base material has a coat of another material that you can use the jewelry laser engraving machine to make the mark. This method is applicable when the original material has to be safe at every cost.

- Laser colouration and Annealing: This process occurs when the laser is repeatedly moved over a surface which results in colouration of the area with higher exposure from the laser. The sharp contrast is however used to create the markings on jewelry.

- Laser Ablation: Laser ablation is the method whereby the surface coating of the material to be marked is engraved. This method provides protection of the material.

A precise jewelry laser engraving machine depends on several factors. Besides the right lens choice, working tables and a corresponding exhaust system, the correct focusing is important. The correct setting of the focus, this means the right distance between the laser head and the material to be engraved.

Optimal results during jewelry engraving are achieved by using different lenses. This works in the same way a camera does. The various lenses differ by their respective focal distances. The focal distance is indicated in inches. This is the distance from the lens to the focus.

2.1. INNOVATIONS OF JEWELRY ENGRAVING MACHINE

The laser engraving machine for jewelry gives the user the freedom to choose between different shapes and engraves on various materials including Aluminum, Copper, Ceramics, Gold, Brass, Silver and even Plastics like ABS, PVC, PP, PE, etc.

Innovation in every technology is important so as to improve the production and competitiveness with similar technologies. The jewelry laser marking machine is not left out of innovations. Hence, laser equipment is a great tool to improve every industry’s productivity, brand image and enables creative design. Metal engraving machines for jewelry are quite flexible and powerful.

When laser technology was first demonstrated in the 1960s, laser engravers for metal jewelry never stopped its growth in all industry sectors. Laser technologies have multiplied and today it is right to say that for every application there is a laser. New materials and new textures are emerging every year, jewelry marking technology helps you stay up to date.

The jewelry laser engraver is now convenient and easy to use and can replace any manual jewelry engraver. The jewelry engraving machine can be used in any retail environment or industrial space, as there are different sizes that can fit into any desired space.

Jewelry laser engraving machine allows you to simulate your material before engraving using the integrated red laser pointer, with no measuring required. The depth nose allows for constant engraving, particularly on uneven surfaces.

Precision, speed, minimum heat increase, fine quality finishing and high mechanical resistance are the peculiar features of jewelry laser engraving machines.

2.2. JEWELRY LASER MARKING TECHNOLOGY

Jewelry laser engraving technology and marking software enable new applications and bring laser marking and engraving to the highest standards. The majority of materials used in the jewelry industry including precious metals, alloys, polymers and ceramics can be processed.

The rugged construction and ease of operation are beneficial to every jewelry company: clamping the rings for internal or external marking with the laser engraver for rings is unrivalled.

Fiber lasers marking jewelry are not new in Industrial Laser Marking, fiber lasers are used for high speed marking of integrated circuits since the late 1990s.

In recent years, fiber lasers have tremendously progressed in terms of flexibility and overall performance enabling what is referred to as the ‘Fiber Revolution’ in the laser market. Fiber lasers marking manufacturers have technological advantages that improve reliability and repeatability of laser processes.

Fiber lasers also offer integration and operational advantages:

- Fiber lasers are compact and deliver their energy through a flexible optical fiber

- Fiber lasers are scalable and more efficient than any other laser technology

- Fiber lasers offer higher and stable beam quality and excellent pulse-to-pulse stability ensuring the best repeatability over time, for critical marking processes

2.3. COMPARISON OF JEWELRY CARVING MACHINES ON THE MARKET

There are two widely used equipment for engraving jewelry generally. It is important that we distinguish the two technologies even though they both use computers to control the machine. The difference between these two machines is that, jewelry laser engraving machine uses the laser source as the engraving energy. The CNC machine on the other hand processes the milling paths which the CAD CAM softwares creates from the drawing and transmits to the control device.

They have some features in common, which include: versatility, they are both safe to operate, they have the same time of production compared to the manual means of engraving and they can work for very long hours.

Difference between jewelry laser machine and CNC system:

| JEWELRY LASER ENGRAVING MACHINE | CNC SYSTEM |

|---|---|

| The jewelry laser engraving machine is not expensive. | The CNC machine is more expensive to acquire and maintenance can be expensive as well. |

| It is easy to operate for a first time user and an expert in operating laser machines. | It requires high technical expertise before it can be operated. |

| Replacement part of the jewelry engraving machine is not difficult to get. | Replacement parts are not readily available should any part of the machine break down. |

| Jewelry laser engraving has a high precision because the diameter of the engraving source is small. | |

| Laser engraving is a non contact process, wear or tear of tools is absent. | Using a CNC machine for engraving, the machine makes contact with the material, hence, wear or tear could occur. |

| The jewelry laser machine versatility makes it suitable for many applications. |

CHAPTER 3. LASER ENGRAVING MACHINE WORKING ON JEWELRY

Pendants, bands, rings, etc are considered valuable when they are engraved or marked with names, initials and other personal inscriptions using a gold engraving machine. Apart from engraving jewelry, laser engraving other gold material, the gold engraving machine can create highly intricate designs on medals and currency coins.

Laser marking technology provides total design freedom that allows for the accurate marking of any design on gold jewelry such as; logos, small alphanumeric characters, texts, or photo designs.

Since gold is a metal that has a highly reflective surface, a fiber laser is a preferred technology to laser marking gold jewelry. Using a laser with a higher energy density, the heat is quickly absorbed by the material. A fiber laser concentrates high energy in an extremely fine laser beam, allowing gold engraving of highly smooth and fine designs.

Silver is not only found in jewelry but also; tableware, utensils, mirrors, solar panels,and more. Silver is a highly reflective material in nature, hence, fiber lasers are also the best technology for engraving silver jewelry. A high energy density is utilised to rapidly generate heat, which is absorbed by the surface of the silver jewelry. This technique is also effective for highly delicate silver such as extremely thin or hollow items.

The fine laser beam, coupled with a high burst of energy, allows creators to achieve highly complex and intricate designs on sterling silver jewelry. A clean and fine engraving is created without damaging the silver material.

3.1. HOW TO APPLY THE ENGRAVING MACHINE ON JEWELRY

Engraving machines provide one of the best modern-day jewelry engraving machines that are precise and accurate with high robustness.

The jewelry marking machine’s high-quality shock absorbers suppress the vibrations produced when engraving and you can experience a seamless engraving on your jewelry. This excellent result differentiates your product from the others. Jewelry engraver machines are highly customizable and contain a built-in software that is state-of-the-art that can automatically update the content with auto-update of serial numbers.

The laser engraving machine for jewelry gives the user the freedom to choose between different shapes and engraves on various materials including Aluminum, Copper, Ceramics, Gold, Brass, Silver and even Plastics like ABS, PVC, PP, PE, etc.

Furthermore, the users can deploy standard fonts and characters for engraving on jewelry. One distinctive feature of the laser engraving machine for jewelry is the engraving of complete photographs on pendants that look fantastic once finished and ready.

Adding a text to a watch, pendant, ring or customizing a bracelet can be achieved with the jewelry laser engraving machine and can mark on a broad range of shapes and materials with extreme precision and speed.

3.2. BENEFITS OF JEWELRY ENGRAVING BY LASER

There is a constant demand for jewelry engraving laser machines. The following are the benefits you can derive from owning your own laser engraver for jewelry:

- The jewelry engraving machine is multipurpose. A single laser system can engrave surfaces of materials like gold, silver, copper, titanium, brass, etc. Another benefit is that the jewelry machine can engrave personalised items such as; rings, bracelets, necklaces or watches, etc.

- The jewelry laser engraver is versatile in that you can create any design irrespective of the complexity, it will be successfully engraved on your piece of jewelry. Whether it’s engraving a photo on a pendant, or adding a unique pattern to a ring, or branding jewelry with a logo for a corporate event, the possibilities of a metal engraving machine are endless.

- The fiber laser jewelry machine makes use of a non-contact technology. A laser beam is directed onto the material surface and produces a mark. As a result, there is no contact between the laser equipment and the material being engraved. Since there is no contact during the engraving process, the jewelry being marked is not compromised. In addition to this, the machine doesn’t have moving parts, which can wear down over time and require replacement.

- There is no doubt that one of the most significant advantages of laser engraving is the time you save. The engraving time using a jewelry laser engraver varies depending on the complexity of design and the depth of the engraving. However, it’s safe to say that the average job takes about a few seconds to a few minutes.

- A major contributing factor to the rise in popularity of the fiber laser jewelry machine is the improvements to the operating software. You don’t need to be an engineer before you can use a laser machine for jewelry. The software is similar to other design apps, such as Adobe Photoshop and Illustrator.

- The laser engraving process doesn’t use harmful chemicals and is therefore an eco-friendly technology.

- Another benefit of the jewelry laser engraver is that it can engrave 3D on curved, round, cylindrical, and other shapes, and surface types with excellent result.

- The jewelry engraving machine does not require any complex software or programming before engraving on jewelry as against the CNC system of engraving.

- The gold and silver laser engraving machine is designed such that there is no loss of precious material during engraving.

3.3. FEATURES AND PROPERTIES OF JEWELRY LASER ENGRAVING MACHINE

The fiber laser engraving machine can mark hallmarks, trademarks, stone weights, personalized text, serial numbers, corporate logos and digital images at up to 200 characters per second. The main properties of every jewelry laser engraving machine include:

High efficiency: Jewelry laser engraving machines are quasi-three-level systems. A pump photon excites a transition from a ground state to an upper level; the laser transition is a drop from the lowest part of the upper level down into some of the split ground states. This is very efficient.

Integrated camera for an optimal viewing of the marking area, allowing users to better position the jewelry to be engraved.

Digitally adjustable Z-axis for an easier focusing of pieces, guided by two high-brightness pilot diode-LASERs.

The Cold-Light technology helps the jewelry engraving machine eliminate both the need to preheat the equipment at start working as well as to use an auxiliary cooling device.

Integrated control for the automatic on/off of the external vacuum device, recommended to be used to filter smokes inside and possibly recoup precious metal dust into provided paper-filters;

Importing files, with a wide range of extensions of images, logos, texts, pictures is possible.

The jewelry laser source has a very high electro-optical conversion efficiency of over 30%. This, however, limits consumption to a few hundred Watts, this makes the 100,000 hours of operation possible.

CHAPTER 4. FACTORS INFLUENCING THE EFFECTIVENESS OF JEWELRY ENGRAVING

In order to achieve a certain engraving on your jewelry, a certain amount of energy is required. There are some factors that can affect the effectiveness of a jewelry laser engraving machine.

Fiber laser power sources will always affect the effectiveness of the jewelry engraving machine. High power will always improve the efficiency of a jewelry laser marking machine.

It is required that when marking is deepened, the parameters of the jewelry laser marking machine have to be adjusted to increase the power and current of the jewelry laser marking machine, this will affect the speed.

The higher the marking density, the slower the corresponding marking speed of the large scale is slower than the small plane. This is why it is best to use a smaller working lens, the reason is that the density directly increases the area marking.

The marking speed of a small format laser marking machine must be more higher than large format laser marking machine. Because the deflection of large format mirrors is much larger, which naturally has a certain effect on the speed of marking.

With the same width, the same spot and the same depth, the higher the marking density, the slower the corresponding marking speed. The reason is that the density directly increases the area of marking.

4.1. TYPES OF JEWELRY MARKING

Jewelry are personal ornaments made from materials like gold, silver, platinum. However, coloured stones are categorised into precious stones and semi-precious stones. Rubies, sapphires and emeralds are precious stones included in jewelry making.

| MARKING | MEANING |

|---|---|

| Any number followed by “K” or “karat” | The item is gold, the purity of the gold varies by karat number |

| “Gold filled” OR “GF” | The piece is mostly made of base metal, but it has a sheet of gold on the surface. |

| “Gold plated” | The piece is made of base metal, and a very thin coating of gold has been applied to it. |

| “Vermeil” | Sterling silver with gold plating. |

| “Sterling” or “925” | This is made of sterling silver. It must have 92.5% of silver metal. |

| “Silver-plated” | The item is base metal with a thin coating of silver on the surface. |

| “Nickel silver” or “German silver” | The item is silver in colour but does not contain any silver metal. |

| “Platinum” | This piece is at least 95 percent platinum. |

4.2. DIFFERENT KINDS OF JEWELRY ENGRAVING

There are three types of engraving that is done on any piece of jewelry.

Hand Carving: This technique of engraving metal is carried out using shaped steel cutters with a sharpened edge which are mounted into a wooden handle. The cutters themselves are supplied in extra-long lengths so that they can be cut down to suit the person using them.

Jewelry engraving designs can be drawn directly onto metal or transferred using a variety of methods. As you start to trace your first line, your hand engraving tool should be pushed down and forward with even pressure. The process is repeated until the required depth of each cut is reached.

CNC Engraving: This engraving method uses a tool that is controlled by a machine to create the engraving. The design is programmed into the computer and etched on the surface according to the desired text or image. There are some drawbacks with the traditional rotary engraving.

While rotary engraving can be very precise, the design of the engraving can is usually very thin. Also, the bit itself needs to be replaced when it gets worn out. Traditional rotary engraving cannot be used on delicate items that are sensitive to heat and pressure. You cannot engrave any jewelry that is made with plastic or glass, because those materials can be damaged with rotary engraving.

Laser marking: The laser technique uses a high powered laser beam to mark on the surface of the material being engraved. Similar to the rotary engraving system, the desired design is programmed into the computer and the laser machine will mark any design on jewelry.

Unlike the traditional rotary engravers, you do not need to worry about the materials that it can marke. Laser markers can be used for materials that are sensitive, like paper. Although paper is not a common material to make jewelry with, it is good to know that no matter what materials you want to engrave, they can be customized with a laser marking machine for metal.

4.3. COMMON USE OF ENGRAVING IN JEWELRY

Intaglios: Engraved gems are not common in today’s markets. They were popular in ancient times during the Victorian times.

Decorative Engravings: Decorative engravings are used to create nice and creative patterns on any silver or gold material using the laser machine for jewelry. Antique jewelry will often have hand-engravings, making them more valuable in comparison to modern pieces produced in mass.

Inscriptions: The most common engraving on pieces of jewelry nowadays are inscriptions. It could be a date, a meaningful phrase, or a small image, inscriptions make a piece of jewelry special to the user.

CHAPTER 5. PRICE, DURABILITY OF LASER ENGRAVING MACHINE FOR JEWELRY

Jewelry laser engraving machines can mark a series of high precision operations, better than manual engraving. We can therefore say that a jewelry laser machine is an investment.

Jewelry engraving machines are almost everywhere in the market and the prices vary according to manufacturer, size and capacity. The question that needs to be answered when considering the price of a jewelry laser machine on sale is that; is the machine part readily available and affordable should a future damage occur?

Although, price does not really mean the jewelry engraver will exceed its stipulated lifetime. The most cost effective and the most suitable for your engraving needs should be selected. It is important to always choose reputable companies with excellent review from past clients; machine warranty and availability of spare parts.

5.1. HOW TO CHOOSE THE BEST JEWELRY ENGRAVING MACHINE

It is possible to have a difficult time selecting the best jewelry laser engraver to meet production needs. These will help you select the ideal jewelry engraving machine.

The power output source of the laser machine for jewelry is the thing that should be checked when purchasing a jewelry laser engraving machine. Engravings on jewelry are always simple, you can choose a fiber laser with minimal power of 20W, 30W or 50W. Although, the power rating of the laser engraving machine does not determine the quality of the machine. Rather, it is a combination of the power source and the core technology, i.e, the sole purpose of the engraving machine that determines the quality of the jewelry engraving machine.

Presently, multiple core laser technologies are available in the market. You however have to choose the product that best suits your need and the material you want to use it to engrave. For engraving jewelry, a fiber based laser engraving machine will fulfill every engraving requirement.

A jewelry engraving machine should be easy to use. The jewelry engraver should have the ability to clamp the piece of jewelry and work on it is most preferable. This clamp should not be stern and fixed in a particular position but should rather have a rotary motion freedom. This will enable the user to work easily on bracelets or rings.

One of the most important aspects of a jewelry laser engraver is the machine’s precision. A jewelry engraving machine with the accuracy of 1mm should be preferred because the result is perfect. Depending on the size of the jewelry, you can choose the precision of the laser engraving machine accordingly.

The software of the laser engraving machine also plays an important part in determining the right machine for your job. The software should enable you to engrave according to an incremental sequence. Also, check the version of the software, its release date and the level of customization that you can achieve with it.

Also, check the customizability of the jewelry laser engraving machine before buying one. Look out for reviews of the jewelry engraving machine for sale online. And see how easily you can change the different settings of the machine. The settings you should be able to change include depth, width, height, auto-incremental feature, and other available features of the jewelry engraving machine.

Price is another factor that needs to be taken into consideration while selecting the jewelry laser engraving machine for your business. Remember, not to go for the cheapest option available for sale. Rather, a good survey of the available models and their online reviews can give you a good idea about which jewelry engraving machine you should purchase.

5.2. MAINTAINING AND SERVICING JEWELRY MACHINE ENGRAVER

The following practices will help keep your jewelry machine engraver last longer.

Cleaning the jewelry laser engraver after every use, at the same time using a vacuum cleaner to suck dust and dirt from the machine once a week.

Chillers are a critical aspect of any jewelry laser engraver and it should be checked periodically. Filters, fans, coolant levels, coolant quality and cleanliness should all be checked on an interval set forth by your machine’s manufacturer.

The reflector and focusing lens should be cleaned. After a period of use, particles settle on the focusing lens affecting the thickness and precision of engraving.

Always check the steel strip and ensure it is tight.

Never touch an optic with your fingers as the dirt from your skin can destroy the coatings on the optics. In order to preserve the optical coatings applied to the lenses and mirrors, use the optics paper and the cleaning solution supplied with the laser machine. Do not use alcohol.

5.3. THE BEST CONDITION FOR USING A JEWELRY ENGRAVING MACHINE

The following conditions are ideal for our laser marking machine. Room temperature between +15 °C and +25 °C (59°F – 77°F). Relative humidity is between 45% and 65% . You should also protect the device from direct sunlight.

In winter, overnight temperatures may happen to drop below the recommended conditions. This can lead to condensation in the laser tube and thus to damage. In addition, greases and oils can harden, affecting the mechanical parts.

Install a frost guard on the heater to keep the room temperature from falling below the optimal +15 °C (59 °F). You can also warm up the room slowly before using the laser. Do not place the laser too close to the heat source, since the warm air could be drawn in as cooling air, causing the laser to shut down due to overheating.

CONCLUSION

In conclusion, you can make a list of your priorities and the materials that you want to engrave. And then choose the ideal laser technology for the product. Jewelry laser engraving machine is a profitable investment that includes no consumables, power use and maintaining cost. Subsequently, If you want to engrave jewelry according to your clients’ demands then you have come to the right place.