Laser Marking Machine Manufacturer

| Professional Laser Marking and Engraving Solution Configuration Expert in China |

Alldo Tech is a laser marking machine manufacturer that focuses on remarkable laser technologies. Our primary laser marking machine are; fiber laser marking machine, CO2 laser marking machine and UV laser marking machine. Each of these laser technologies has specific materials they mark and engrave permanently.

Alldo Tech fiber laser marking machines are designed to mark and engrave on metals and some nonmetals. The CO2 laser marking machine is applicable in marking paper, acrylic, leather, fabrics. The UV laser marking machine on the other hand is applicable in marking acrylic and glass.

We are a laser marking machine manufacturer that gives the highest quality of marking and engraving on all products through our laser machines; and our laser machines are long lasting, eco friendly and affordable. We guide you through the use of your machine after purchasing from us and we guarantee you a 12 months warranty on all products.

Alldo Tech Laser Marking Machine List

The stationary fiber laser marking equipment is an average desk size laser machine that is easy to move around. It is suitable for marking metals and nonmetals.

Alldo split fiber laser maker is a compact design that takes up very minimal space and it is used to make permanent marks of metal and partial nonmetals.

Portable fiber laser marking machine is portable and not heavy to move about. It is applicable for marking in a fast production metal and nonmetal company.

Alldo mini fiber laser marking machine is composed of both a laser and an inbuilt computer. It is suitable for marking metal and nonmetal materials.

Alldo desktop laser marking machine is composed of a rectangular platform on which the laser beam and monitor is attached. It is suitable for permanently marking metals.

Alldo enclosure laser marking machine is a compact design where marking of metal and nonmetal is done in the enclosed machine. The control buttons are right at the bottom of the machine.

Alldo stationary UV laser marking machine is a desk design consisting of its own monitor and other laser components and it is used for marking glass and acrylic.

Alldo split laser marking machine is a compact design that is simply easy to move around for fast moving production. It is applicable for marking glass and acrylic.

Alldo stationary CO2 laser marking machine is a compact desk design that is easily wheeled around. It is applicable for marking during fast productions.

Marking area: 110*110mm(Customized) Application: Glass/wood/leather/plastic/acrylic/paper/PVC, etc.

Alldo split CO2 laser marking machine is a compact size that houses the beam, marking space and control buttons, it is easy to carry and suitable for marking nonmetal objects.

Alldo high power laser marking machine is composed of large component parts that requires more space to fit in. It is suitable for direct nonmetal marking.

Apply Our Best Quotation

How to Choose a Model?

Application Areas of Mini Fiber Laser Marking Machine

Laser marking and engraving are the ideal solutions for endless applications, please choose your target area

Marking on Jewellery

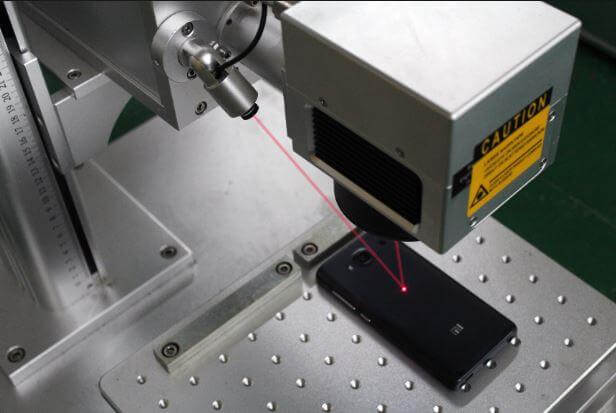

Marking on Phone

Marking on Tools

Marking on Bearing

Marking on Switch

Marking on Gear

Marking on Bolt & Nut

Marking on Knife

Marking on Hub

Marking on Equipment

Marking on Brake Disc

Marking on Connecting Rod

Leave us your materials and industries!

Ultimate Laser Marking Machine Buying Guidefrom Laser Marking Machine Manufacturer

- Chapter 1: Development and Application of Laser in the Marking Industry

- Chapter 2: Introduction of Laser Marking Machines Available in the Market

- Chapter 3: Laser Marking Machine Application

- Chapter 4: How to Choose a Suitable Laser Marking Machine

- Chapter 5: How to Configure Laser Marking Machine to the Production Line

Chapter 1: Development and Application of Laser in the Marking Industry

From pharmaceuticals to medicine, communication to marketing, entertainment to automotive, laser marking machines has led to influential innovations. The guide contains all you need to know when purchasing a laser marking machine.

1.1, How Various Materials Were Marked Before the Invention of Laser Equipment

Engraving Is an art inculcated deeply in human history and culture. A chiseled shell in Java, Indonesia, dating back to between 540,000 and 430,000 years ago, is regarded as the first marked material. Ostrich eggshells with hatched bandings found in Diepkloof Rock Shelter South Africa, dating back to around 60,000 BC, takes the second spot in human’s long history of engraving.

Explorers from ancient Egypt, Greeks, Romans, and most other notable empires that led to world civilization since time inception have drawn from the artistic feel and symbolization that comes with engraving items.

The Art of the Upper Paleolithic for engraving on bones & ivory and petroglyphs for engraving on rocks was the first marking known to man. Metal and jewelry engraving became dominant in the 1st millennium BC—engravement of metallic items were mostly carried out by chasing or lost wax casting. At the dawn of the first century AD, usage of acidic, caustic, and abrasive substances paved the way for glass engravement.

Etching—using strong acid or mordant to cut into the unprotected part of a metal—took over the engraving industry in the 19th century. With the rise of efficient and straightforward marking solutions, the price and cost of engravement became affordable. This innovation led to unperturbed growth in the global market.

At the dawn of the 20th century, the rise of traditional engraving techniques such as burin and use of machines brought about vital innovations in the Jewelleries, glass, metal, wood, and paper industry.

1.2, History of Laser Development in the Field of Marking

The Research and Innovation industry—which has grown to become a dominant part of the 21st-century market—introduced a new style and method of engravement. From Albert Einstein’s theory on the emission of light, Charles Townes and Arthur Schawlow drew theoretical analysis and conclusions that led to Maser’s creation.

‘Microwave Amplification by Stimulated Emission of Radiation’ MASER is an ‘ammonia gas microwave radiation machine’ capable of marking metals and other objects without burning or destroying it. While this innovation’s durability proved more reliable than the traditional techniques the engravement industry relied on, its reliability on ammonia gas stood as a significant problem.

Going back to the drawing board, Charles and Arthur, theorized concepts that led to the creation of Light Amplification by Stimulated Emission of Radiation {LASER} in 1958. The engravement sector was set to birth a multibillion-dollar industry behind the Laser technology after a published paper describing the laser tech in the journal of the American Physical society went viral.

In 1960, Theodore Maiman invented the first ruby laser. Laser marking machines didn’t resonate as the next big thing until affordable microcomputers arrived in the late 1970s. Will Dahlgren’s computerized engraving machine led the revolution. Zarden saw the potential in the automated machines and anted up money for LMI to produce their first machine—laser was becoming widespread by the late ’80s but was not still portable enough to attract a suitable market.

Steve Garnier and John Doran designed the first potable laser marking machines that didn’t have to rely on art but computerized graphics. This invention led to the creation of the desktop laser marking machines and have ever since, led to prototypes of similar nature.

Chapter 2: Introduction of Laser Marking Machines Available in the Market

Before we dive into the types of laser marking machines in the market, let’s talk have a glimpse about how laser marking systems operate.

Such as a CO2 laser can be seen as a tube with mirrors at either end. This tube is pumped full of gases such as nitrogen helium and carbon dioxide. Applying electric energy to this tube creates a vibration that excites the molecules contained in the container to produce light that bounces across the mirrors at both ends. The laser wavelength is determined by the energy gap between the different electronic, rotational, and vibrational state of the tube.

2.1, Fiber Laser Marking Machine

The working principle of fiber laser marking machine is to expose deep matter by evaporation to the surface material or to burn material with laser energy light to acquire pattern or design.

To tact a permanent mark on the surface of metals, you would need a fiber laser marking machines. Fiber laser marking systems come in different shapes & sizes and are regarded as highly efficient, market-friendly resources for engraving various metals. These machines possess a pulse frequency from 1 to 500 kHz.

These marking machines are called ‘Fiber lasers’ because of the fiber laser beam it comes with. The fiber beam is capable of leaving a permanent mark on the surface of gold, aluminum, copper, silver, tin, platinum, and many other metals. Fiber laser marking machines are widely enjoyed in the business, education, DIY, and manufacturing industry.

The laser marking system durable and portable design makes it a suitable machine for customizing engravings on pieces of jewelry, phones, electronics, wrist washes, etc. It possesses a high transfer rate of electric optical—this helps saves cost in running the machine.

While the fiber laser etching machine is widely regarded as the ideal equipment for engraving metals, it can, in a few cases, serve as a suitable option for marking non-metals. Operating a fiber laser machine can become complicated at some point. It’s essential you stick with the user manual that comes with purchase until you are familiar with all its intricacies.

Note that the endless growth and innovation the engravement industry have enjoyed over the years has left different names in the minds of buyers. Don’t be surprised if when trying to purchase a fiber laser marking machine, you come across terms such as fiber laser marking equipment, fiber laser engraver, fiber laser system, fiber laser etching machine, fiber laser printing machine, etc.

To skip the headaches and hoax that can come from scouting the internet for a reliable fiber marking machine manufacturer, explore our store—some of the fiber marking machines available in our collection include 20w fiber laser, 30w fiber laser, and 50w fiber laser.

2.2, CO2 Laser Marking Machine

The working principle of CO2 laser marking machine is the mixture of different gas in the laser tube source. The content of the gas determines the extent to which the air pressure changes and the depth of pattern or design drawn.

The constant advancement in technology has helped pioneer the creation of different laser marking machines. CO2 is the most common laser marking machine available in the market.

These laser marking machines are known for their tube-like nature with mirror edges and the mixture of different molecules contained in the tube. CO2 laser marking machines produces a long-wave infrared light that can be used to engrave materials such as wood, glass, acrylic, fabric, paper, stone, ceramic, plastic, and coated metals without tearing the material apart.

CO2 laser marking machines is typically suited for engraving non-metals and materials with low capacity to conduct heat. When looking to purchase the plastic printing laser machine, one of the major factors to consider is the size of the tube containing the mixed molecules—this is placed as a high priority feature because its size determines the energy or power a CO2 laser machine can generate.

The CO2 laser marking machine tube is usually made of glass, metal, or ceramic. Just like the fiber laser marking machine, which comes at different ranges and prices, some of the CO2 laser marking machines available are 20w CO2 laser, 30w CO2 laser, 50w CO2 laser, and 100w CO2 laser.

Some of the benefits that come with engraving with the high-power marking machine are,

- Marking machines help to eliminate the possibility of spoilage or breakage when marking a product.

- Reduce the risk of external leftover solvent on an engraved item,

- Eliminates maintenance cost,

- Create customized engraving pattern

- Low operational cost.

CO2 laser marking machines are best suited for non-metallic marking or engraving in the manufacturing and production industry. The engraving machines’ portability leaves room for small business owners to partake in the opportunities CO2 lasers bring to different sectors. If you require the laser marking system in different sizes at affordable rates, please don’t hesitate to explore our collection.

2.3, UV Laser Marking Machine

The UV laser marking machine adopts cold processing instead of thermal processing. This working principle enables it bypass the restrictive influence fineness and heat has on most traditional laser marking machine.

Ever thought of marking your product in such a way that the competition would not be able to counterfeit its originality without the risk of leaving traces that leads back to you? The UV laser marking machine can help you do just that.

This laser marking system is notable for the lifetime branding opportunities it brings to the pharmaceutical, medical, and cosmetic industries. UV laser marking machines durability best suits sterilization and disinfectant products printed circuit boards and consumer electronics.

UV laser marking machines emits optical lasers relatively higher than infrared. Its refrigeration in a water chiller determines consistency in a UV laser system’s operation. UV machine’s short processing time and reliability in eliminating issues that can lead to burns or spoilage gives it an edge above infrared machine.

When it comes to projects that require micro precision machining, the UV engraving machines undoubtedly takes the top spot. This laser machine emits energy within a short wave-length. The UV laser marking machine can be used for engraving different glass crystals.

Some of the industries where the marking machine is highly appreciated include research and innovation, pharmaceutical, automotive, medical, OEM, food and beverage, arts and crafts, cosmetics, ceramic cutting, measuring tools, glass, crystal products, etc.

Like most other marking machines available, the UV laser engraving machine comes at different sizes and prices. 3w UV laser, 5w UV laser, and 8w UV laser are the dominant names in the market. Alldo Tech is here to help you achieve the much-desired business goal by providing highly efficient laser marking machines—you can check out our store for a UV laser marking machine that suits your business needs.

2.4, MOPA Fiber Laser Marking Machine

The MOPA fiber laser marking machine uses an oscillator to produce a coherent beam. This working principle creates room for the optical amplifier to operate on an estimated focal point while regulating the input and output of power to the oscillator.

Want to tap into the endless potentials scalability can bring to your business? Master Oscillator Power Amplifier MOPA is the much-awaited design. These MOPA fiber laser machines possess a pulse frequency from 1 to 4000 kHz and can be used to engrave various colors into stainless steel.

The efficiency of the MOPA fiber marking machine is determined by the power amplifier, while the master oscillator determines the coherent beam. This laser marking machine is regarded as a reliable choice for industries dealing with the engravement of metals. Some of such industries include automotive, scientific, jewelry, mining, etc.

MOPA fiber laser machine does similar functions and engraves the same materials as the fiber laser marking machine but in a unique way. The MOPA fiber engraving machines are suitable for carving colorful patterns on stainless steel metals such as gold, silver, nickel, copper, carbon steel, platinum aluminum, etc. While the fiber marking machine engraves on the same metals, its durability doesn’t go as far as marking patterns in different colors.

In situations where you are looking to engrave with speed and deepness, the fiber marking machine might resonate as a more suitable option compared with the MOPA fiber marking system—the need for change in color and mapping pattern slows the process a bit.

Existing with the sole intention of serving our customers to the best of our ability is one of our operations’ key factors. Our store contains MOPA fiber marking machines of different sizes and price, to know which would best suit your business needs, we advise you to book a call through with our customer support representative.

Chapter 3: Laser Marking Machine Application

Since engraving or marking metals became a commercial commodity in the early 19th century, almost every industry has dived into the limitless potentials it offers.

The finance industry remains amongst the most dominant in the engravement industry’s long history. From marking coins and other metals with tools such as burin to engraving the paper currency with CO2 laser marking machines—the finance industry remains at the top of the food chain.

Let’s take a look at some of the materials the marking machine can be used on, and a few industries were the laser marking machines reigns dominant.

3.1, What Materials Can be Marked with Laser?

With the different varieties of laser marking machines available in the market, it wouldn’t be a surprise that there is no limit to the type of materials that can be marked with lasers. Since we don’t have all day nor time to list them all, let’s state the dominant ones and a suitable laser marking machine.

Materials that can be marked with laser marking machines:

- stainless steel

- aluminum

- gold

- silver

- copper

- plastic

- acrylic

- glass

- crystal

- fabric

- stone

- wood

- paper

3.1.1 Laser Marking Machine for Metal

Metals are among the few materials that have a long history with engravement. Marking of metals became dominant in the 1st millennium BC. Metals where first marked via chasing and lost wax casting. Their durable and highly corrosive nature makes the marking process an intricate one. Today, engravers regard laser machines as the most efficient form for marking metals. Though the nature and style of marking are dependent on the type of content/design you want to engrave.

- Stainless steel: MOPA fiber marking machine is the most suitable system for engraving designs on stainless steel. MOPA engravement machines are renowned for the colorful syntax and deep engravement they provide. Note that fiber marking machines can also be a perfect fit if you are looking to mark stainless steels at a fast rate—though you might not be able to enjoy the colourful carvings MOPA machines provide while using a fiber marking system.

- Aluminium: either fiber laser marking machines resonate as a perfect choice for drawing patterns of designs on aluminium.

- Gold: fiber marking machines are used for gold marking.

- Silver: fiber marking machines can create the right pattern on your silver any day anytime.

- Copper: fiber marking machines brings speeds, precision and depth to marking copper.

3.1.2 Laser Marking Machine for Plastic, Acrylic

Unlike metal engravement, marking plastic or acrylic requires a more delicate laser machine due to its fragile nature. Marking of plastic didn’t become a dominant trend until the dawn of the 1st century AD. Ever since its inception, its engravement process has enjoyed rapid growth across numerous industries.

When marking a plastic or acrylic object, CO2 laser marking machines should be your preferred choice. Its low capacity to conduct heat guarantees a safe, efficient, and durable marking process. The CO2 laser marking machine comes in different range and size—you can always put a call through for a customer support agent to help you pick the right CO2 laser marking machine compatible with your plastic and acrylic marking needs.

3.1.3 Laser Marking Machine for Glass, Crystal

Glass and crystal marking started in the first century AD. At inception, the use of acidic and abrasive substance stood as the much-needed engraving material. While abrasive substance dominated its growth in the commercial market, its reliability and durability didn’t hold firm—and so couldn’t last long in the industry due to the risk involved.

Today, glass and crystal can be easily engraved through the UV laser marking machine. UV’s optical layers and short but durable wavelengths can help engrave complex or complicated patterns into glass and crystal without fear of breakage.

3.1.4 Laser Marking Machine for Fabric

Even when the engravement industry started making a name for itself in the early 19th century, no one thought marking of fabrics possible. Knitting and sewing looked tangible enough for individuals looking to design fabrics in different patterns.

Dye and inks were the first substance used for fabric engravement. While this method is still widely enjoyed, its dominance is on a decline. CO2 laser marking machines have become the new trend in fabric engravement. The smooth, risk-free patterns and designs CO2 laser marking machines offer eliminates the risk of eternal leftover solvent. You can utilize C02 in engraving fabrics rest assured a crisp and clean process is guaranteed.

3.1.5 Laser Marking Machine for Stone

Stone is amongst the first materials engraved on. From the thousands of engravements found in numerous tombs in ancient Egypt to the statues and empires that roamed large in medieval Rome, stone engravement is an undeniable part of human history.

Petroglyphs were the first known equipment for stone engravement. Today stones and rocks are engraved using CO2 laser marking machines. Stones possess strong with rough edges, to use the CO2 laser marking machine to engrave patterns on them expertly, the right laser type, and strict adherence to the machine manuals are required.

3.1.6 Laser Marking Machine for Wood

Engraving patterns on woods comes with a unique and beautiful appeal. It can encapsulate the mind of the designer and the hearts of spectators lucky enough to view the finished work. The use of burin and other tools was an industry-wide trend within the first century AD.

Today, wood engravement can be done via the CO2 laser marking machine or the UV laser marking system. Both machines are known to provide long-lasting results for sculptors and designers looking to engrave unique patterns in woods or similar materials.

3.1.7 Laser Marking Machine for Paper

Creation of finely tuned children storybooks and hardcover pages with imprinted signs and patterns are amongst the few innovations engravement on paper have brought to the global market on a vast scale.

While ink and print reigned dominate in engraving paper within the first century AD, its impact doesn’t hold many stances in today’s market. Paper engravement has enjoyed a new phase of design and creation since the invention of the CO2 laser marking machine. Doesn’t matter the type of paper you want to engrave a design or pattern on—you can always rely on the CO2 laser marking machines to do a remarkable job.

3.2, What Industries can be Marked with Laser

Are you trying to map out how marking machines influence the world from an industrial standpoint? Let’s take a glimpse.

3.2.1 Automotive Laser Marking

A lot of components used in the automotive industry are quite sensitive and require marking. While some are marked based on shipment, others are marked based on their rarity in the market—and to ensure permanence, lasers remain the most suitable tool for marking items in the industry.

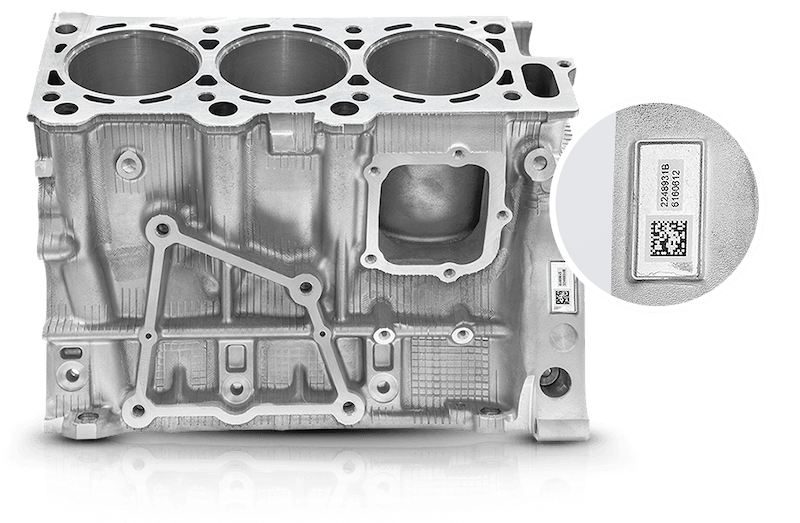

Some of the components widely marked in the industry include seatbelts barcodes and serial numbers—using CO2 or UV marking machines, engine components—engine blocks, crankshafts, wiper blades using fiber marking machines. MOPA marking machines can help illumination of a few automotive parts that require visibility at night.

3.2.2 Electronic Components Laser Marking

Electronic components are delicate. Most electronic components possess a similar nature, color, and size but perform different functions. Marking components with Laser machines aids electronic engineers in deciphering suitable components for each device.

Some of the components laser marked for use in the electronic industry include semi-conductors, housing units, circuit boards, etc. Laser marking electronic components has helped improve scalability and safety for industry experts.

3.2.3 Jewelry Laser Engraving

We are quite certain it wouldn’t come as a surprise that lasers are used in jewelry engravement. From the dawn of human civilization, laser engravings on jewelry have represented different things in different cultures. Fiber marking machine is the one formidable laser systems used in the industry.

3.2.4 Watch Laser Engraving

Engravement on wristwatches dates as far back as the 19th century. Today, product developers use laser marking machines to tact most of the engravement found on wristwatches. Engravement on wristwatches can be carried out via a fiber marking machine or a MOPA fiber marking system.

3.2.5 Barcode Laser Marking

Barcodes have grown to become a relevant part of almost every industry. A barcode reader machine can enable you to verify the manufacturer, price, and type of item you are about to purchase. The easiest way to make a barcode stick on an item is via a laser machine. Engraving barcodes can be done via Fiber, MOPA, C02, or UV marking machine depending on the type of object you want to engrave a barcode on.

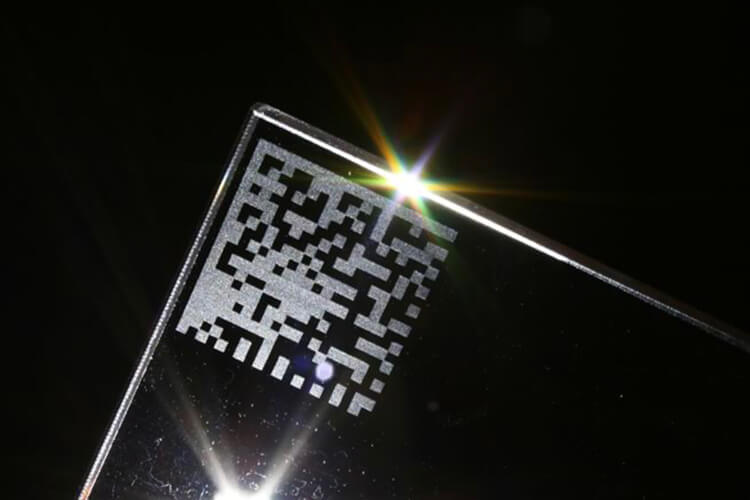

3.2.6 QR Code Laser Engraving

The quick response code is here to stay. From digital scanning of sequence in phones to authentication of products and machines from the company—its presence is already dominating the 21st-century market. Be it wood, ceramic, stones, metals, etc.—the right laser machine can help make QR codes stick permanently on any surface.

Chapter 4: How to Choose a Suitable Laser Marking Machine

We have looked at the history of marking, the industry’s growth, the dominance of laser marking machines, the type of laser marking systems available, the laser’s scalability and reliability in numerous materials and industries. Its high time focused on features that can enable you to pick the right marking machine for your business.

4.1, Laser Type

Lasers come in different types. And each type is designed to cater to specific needs and requirements. Most laser types come with different wavelength, pump source, laser medium, and mode of application. These laser types are all designed for specialized research. For instance, the fiber laser marking machines is a suitable fit for barcodes and scanning designs in metals. In contrast, the gold MOPA fiber laser marking machine is suitable for marking colours into stainless steel, though they both share a similar feature—electric discharge.

While the fiber laser marking machine, discharge is similar to that of the MOPA fiber laser, usage and durability are different. Many business owners get confused in trying to pick a suitable laser machine for their business needs due to difference in laser type. The factors below must be put into consideration when purchasing a laser marking machine;

- Your marking needs

- Your industry

- The material you want to mark

- Estimated budget

To cut the long process short, you can easily put a call through to our 24 hours support team—they can help you navigate the type of laser with a compatible marking machine that would suit your business needs.

4.2, Power

Power remains a major source of concern when purchasing a machine in any industry. Excessive power consumption can lead to instability and loss of profit. Such factors have made obtaining power saving laser marking machines essential for every business owner.

The amount of power Laser marking machines consume is dependent on the type of machine and workload allocated. A 50w fiber marking machine made to work for over 10 hours would certainly consume more power than a 20w fiber marking machine made to work the same 10 hours.

To ensure that you are on the right part, vet the marking needs and requirements needed to keep your business running efficiently before scouting for a suitable marking machine. Consider factors like;

- Your daily marking needs

- Power supply available

- The size of your business

- The type of laser and marking machine that is dominant in your industry

While most of the laser marking machines contained in our store are optimized to consume minimal power, there is no guarantee that you wouldn’t run into power issues if you don’t carry out thorough research regarding the above-listed factors.

4.3, Marked Area

You are looking to purchase a marking machine; it’s evident you want to engrave designs on a particular material. Have you estimated the area of the material you would like to mark?

For instance, let’s say you want to engrave QR codes on newly designed facemask so users can easily identify your brand. Since you can’t go about marking any side, picking a specific area is necessary. Before you go into market research regarding the type of laser marking machine to buy, ensure you have marked out the are most suitable for engravement on your product.

Knowing the area you want to mark will enable you better understand the precision and durability required from the laser marking machine you need to purchase and reduce the time needed for market research.

4.4, Marking Depth

How deep do you want to engrave the barcode, QR code, serial number, the pattern or design you are looking to engrave on a specific item? The marking depth gives you inside information on the type of laser required for the job.

When you know the marking depth, you will be able to navigate the portability a marking machine would have to possess to help you do your job well. Knowing the marking depth required aids in deciphering the principles and wavelength surrounding the laser marking machine that would be suitable for the job.

4.5, Marking Material

Are you trying to engrave symbols on metals or signs on ceramics? What’s the texture of the material, and how long would you like the marked pattern to last? In situations where you are trying to engrave patterns on metals, you might want to also consider the metal’s color.

Every laser marking machine available in the market are designed to serve specific purposes. They come in different types, size, and range. Machines such as the Fiber marking system and the MOPA fiber marking system are suitable for marking metals but in different ways.

When you put the type of material you would like to mark into consideration, you will be able to pinpoint the exact laser marking machine suitable for the job.

4.6, Price

It all comes down to price. Without an estimate of your budget, you wouldn’t be able to navigate a laser marking machine that would suit your business needs. The price of laser marking machines varies based on size, laser type, and industry.

It’s advisable to put a call through to our support representative to run a rough estimate of how much a marking machine is compatible with your business needs will cost. This single task can help give you a favorable standpoint when considering other factors contained in our list.

4.7, Maintenance Costs

Diving into an ocean without a probable viewpoint of what the tide is like is catastrophic. You might be able to navigate a laser marking machine that resonates with your business needs without much stress, but with little to no prior planning on the maintenance involved, you will end up at the losing end.

Maintaining a laser marking machine is not very expensive. Still, it can become a burden if proper business budgeting is not created to pilot its maintenance. Before buying any laser marking machine, estimate the maintenance cost, and chose depending on which would be beneficial to your business in the long run.

4.8, Durability

You know the height you would like to take your business to. You have an estimate of the competition standpoint and a strategy to keep your company leading the competition. Now consistency is all that’s left.

When scouting for a laser marking machine, your viewpoint should be focused on the long run. The machine’s durability to withstand favorable and thorny rides must be put into consideration. Purchasing any laser marking machine without clear viewpoints backed up with credible facts regarding its durability can hinder business growth.

Chapter 5: How to Configure Laser Marking Machine to the Production Line

Nobody likes it when an element interrupts the production flow. Fiber laser marking machines are designed to withstand a complex production line. The on the fly laser marking system can be configured to withstand neck-breaking speed.

To configure to the production line, you would have to make a digital design of the pattern, serial numbers, barcode, or QR code you would like to engrave into the metal. The fiber laser marking machine takes about 1.4 seconds to leave a permanent mark on the material.

With the pattern well aligned, you can keep the fiber laser marking machine working all day without having to break the production line unnecessarily.

5.1 Application of Laser Marking Equipment in Production Line

Like we made obvious earlier, numerous industries bank on the durability marking machines provide to keep the production line in good shape. The automotive industry uses the fiber laser marking machine to mark engine parts, seat belts, and numerous other parts of an automobile, while the electronic industry bank on the fiber marking machine to tag newly designed semiconductors.

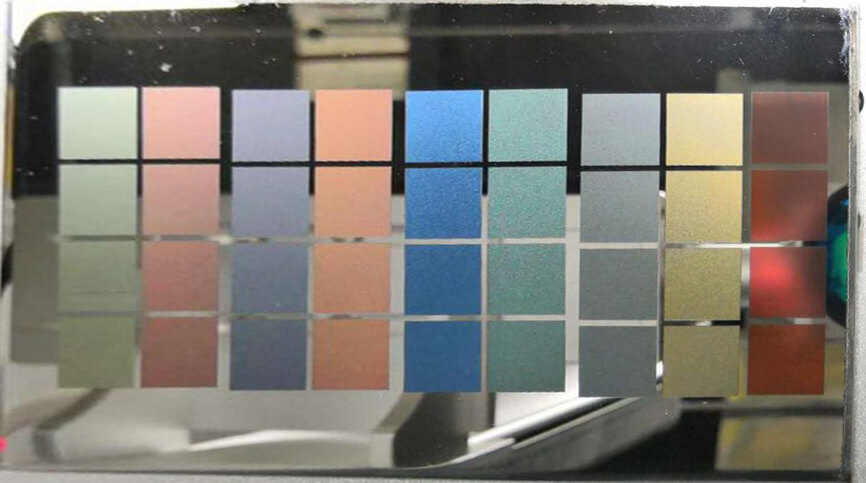

Laser marking equipment can be used in the production line to create high quality, high-contrast marks. When used in the production line, the concentrated beam the laser marking equipment provides leaves a readable or scannable mark on any surface subjected to its ray.

The safe and efficient manner at which the laser beams provides a unique traceability sequence has made it one of the few marking equipment manufacturers can rely on. Whether you are looking to engrave text, unique ID codes, or machine-readable data—the right laser marking equipment can help keep the production line running.

5.2, We Can Provide the Entire Production Line Solution

Without powerful and excellent product line solutions, the manufacturing team would certainly experience numerous setbacks while tacting laser designs.

Do you desire product line solutions that can provide accurate markings within very short manufacturing cycles?

Need fiber, CO2, UV, or MOPA fiber laser marking machines with solutions that are compatible with a program to program mode of communication?

Or maybe you are in search of product line solutions specially designed to suit your business needs?

AT Alldo Tech, your satisfaction is our key priority. Our research and development team is made up of experts with proven credibility in the Research and innovation industry. We provide diverse laser marking equipment to suit multiple industrial needs and customized business specifications.

With Alldo Tech, you can rest guaranteed all the laser marking equipment required to keep your production line running is handy—get in touch.

Get In Touch