We Know How

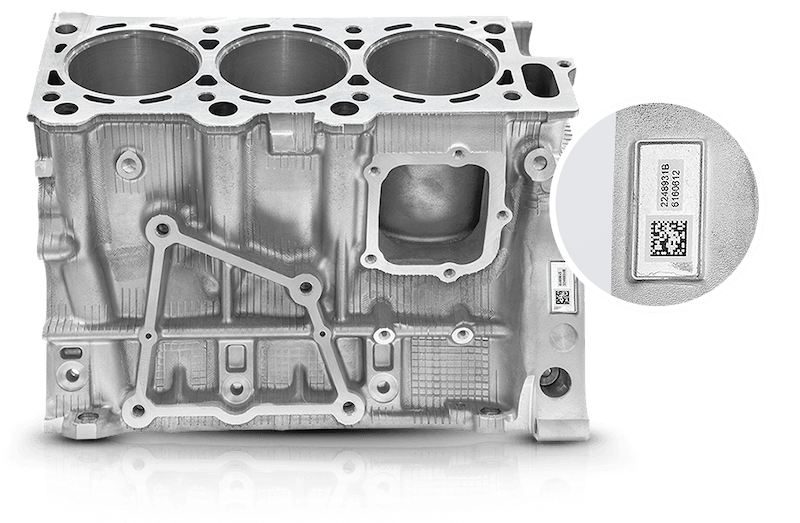

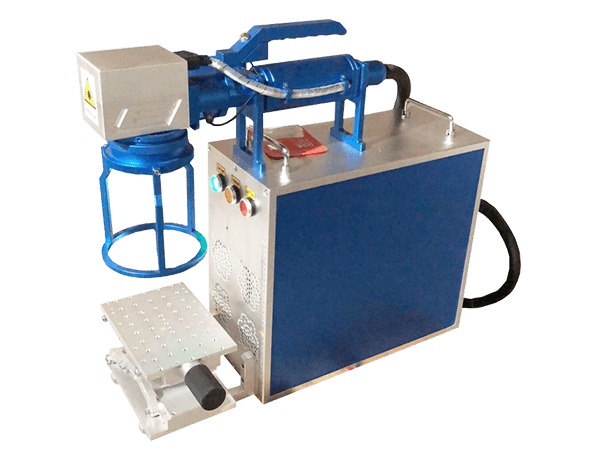

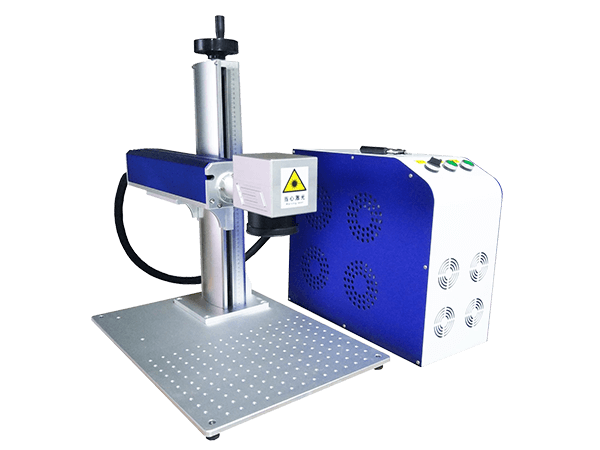

Alldo Tech metal laser marking machine is capable of engraving images, letters, logos, signs, barcodes, serial numbers and other means of identification on all materials. We offer you only the high quality metal laser marking machine at the best price you can ever find.

Laser engraving machines for metal are used to permanently engrave legibly, and quickly on hard and soft metals such as aluminium, steel, stainless steel, magnesium, lead, and zinc. On these materials, deep laser marking is made through a deep penetration process into the component being processed.

The annealing process occurs on the stronger metals such as iron, steel, stainless steel, where there is no damage done to the surface structure , and the mark is permanently done using a laser engraving machine for metal. This is possible because annealing on materials such as steel-alloys enables corrosion-resistant marking. The heat reaches a depth of 0.1 to 0.6 mm when laser is applied on metal.

What Machines You Can Choose

Choose the Top Technology for Metal Marking and Engraving

High Speed & Stability

Achieving a marking speed of 8000mm per second, the marking will not freeze, and its stability.

Competitive Prices

Alldo Tech is a manufacturer with a competitive price and accepts worldwide agents.

Custom Different Depth

The standard equipment configuration can achieve a marking depth of 0.6mm.

No Maintenance Costs

It has no consumables, the parts have a long service life and require almost no maintenance.

Alldo Tech metal laser engravers are tested over time as they are abrasion proof and UV resistant. Environmental friendliness is our watchword; we provide the most environmentally friendly metal laser that does not use contaminable chemicals. Metal laser seamlessly engraves all items, from, steel, to metal, plastic, and so on.

Not only do we give you the best, we also provide you with consultation and guidance on the best type of metal engraver for your company or project.

Feedback from Our Clients

Before discovering Alldo Tech marking machines, their company had great difficulty handling the cooling system of the first laser marking machine, and this has resulted in pretty much troubles for the company. With Alldo Tech laser marking machine comes dual air-cooling systems. With faulty cooling systems, you cannot have well defined beautiful markings.

The instructions could be a little better, but once you understand how it works, it is a great metal laser engraver that can get very accurate laser images from basically a picture. I have been using this to laser images through lacquer paint for salt water and acid etching of metal. I have also used this to laser images on matte black , ceramic filled auto paint and black anodizing. It makes very clean, clear images. Everyone that sees them is very impressed with the laser ability.

The most impressive thing for me was the detail that this laser is capable of. I can literally engrave fonts that are around Size 8 and they burn crystal clear with my settings. I suggest doing a lot of experimenting because in the end, once you get the right calibration, this thing is capable of incredible detail and quality engravings on metals. You may also want to mess around with the contrast settings if you are engraving complex images. For tiny details, you may want to try using the lowest possible settings in depth/power (low, but still enough power to leave a mark).

I was worried when I received it as the shipping box was pretty light. After following the manual, it was pretty easy to set up. I was under the impression this kind machine normally would be heavy and big. Instructions were easy to understand. And the software is quite easy to understand. Very light , easy to take .It is a cool laser engraver on metal and jewelry. Love it!

My first laser engraving machine and it didn’t let me down. All I had to do is to connect a USB cable to my laptop and a power cord. It comes with the driver inside the shipping box so no problem installing the driver. What’s nice was inside the usb drive, it has a step by step video to setup and install everything which is very neat for beginners like me. It took a while to print my first engraving on metal and it came out all good.

FAQs About Laser Marking Machine for Metal

Metal Laser Marking Machine

Ultimate Buying Guide

Contents//

CHAPTER 1: INTRODUCTION OF LASER MARKING MACHINE FOR METAL

Laser marking machines for metal can mark permanent images, letters, logos, signs, barcodes, serial numbers, etc on materials such as aluminium, stainless steel, magnesium, lead, zinc, plastic, etc.

With the advanced third generation solid fiber laser generator, high quality galvanometer, field lens, and PC and software, marking can be done on any surface. Laser engraver for metal features stable output power, fast marking speed, fine effect, high efficiency and maintenance free.

1.1 EARLY METAL MARKING MACHINES

Humans began marking materials long before the development of modern laser engraving machines for metal. The earliest engraving example we can cite was made between 430, 000 and 540,000 years ago. In the 1st Millennium BC, humans began metal marking using techniques that allowed for shallow grooves, such as lost-wax casting and chasing. It was around this time that they also began engraving gemstones such as jewelry and decorative pieces.

Centuries later, as Europe emerged from the Dark Ages, Middle Age metalworkers began engraving decorations and signatures onto their work. In 1430, the Germans began using printing plates, so that they could somewhat quickly print designs onto metal. Engraving was extremely popular among the Germans and the Italians throughout the 15th century.

Towards the end of the 15th century, Europeans discovered etching, which then edged out engraving. German metalworkers in particular were fond of etching decorations into items such as guns, armor, plates and cups, using iron plates.

1.2 HISTORY OF MODERN MARKING MACHINE ON METAL

During the Industrial Revolution, the transition began from hand to mechanical stamping, with steam-powered presses which was the modern equivalent of a hammer and anvil.

In 1870, the Prussian Army issued stamped identification tags for its troops for the Franco-Prussian War. They were referred to as “Hundemarken” (the German equivalent of “dog tags”) after a similar identification system instituted for dogs in Berlin.

During the 20th century, governments around the world sought to standardize the market and create conformity standards for laser marking machines for metal. For example, in the European Union in 1984, legislators commissioned the CE mark. Ever since then, marking capabilities and applications have improved.

The CE mark, which alludes to the Conformité Européenne (European Conformity) standards, as they are informally known, is a literal mark that can be found on compliant products and equipment. Meanwhile, in the United States, Canada and other nations, legislators followed suit with their own conformity standards and versions of the CE mark.

1.3 MODERN MARKING SYSTEMS

Marking systems are made up of machines used to emboss, etch, stamp, or print designs on as many material surfaces as possible. Marking systems employ many techniques and marking tools such as laser markers, press markers, dot peen machines, and nameplate markers. Other marking tools include presses such as embossing machines, engraving machines, roll or rotary marking devices, hot stamping machines, numbering machines, and etching machines.

CHAPTER 2: TECHNIQUES AND TOOLS FOR MARKING NOWADAYS

Many techniques and tools are incorporated in products manufacturing in modern times. The most notable is the laser marker, others are press markers, dot peen machines, nameplate markers, etc.

Laser marking on metal is an environmentally friendly process that utilizes a high energy beam of laser radiation to directly mark the surface of materials. Types of laser markers are classified according to the length of the beam and this length is determined by the properties of the material being marked and how well the material responds to laser energy.

Press markers, or presses, can make fast, permanent marks, but they are not very flexible and are time consuming to set up. They also cannot be used on hard or fragile parts and can be dangerous to operate.

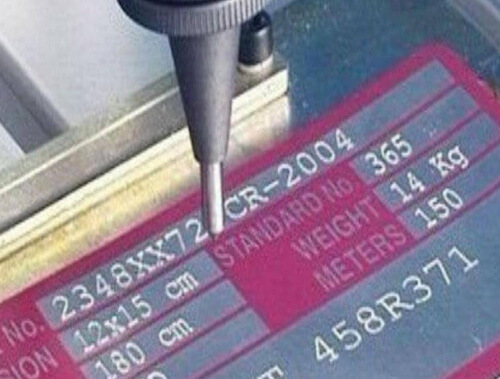

Dot peen machines, also known as dot marking machines or pin mark machines, mark objects with a sequence of closely spaced dots. They do so using a fast and accurate micro-percussion mark system. Dot peening does not create stress or remove material.

Nameplate markers, as the name suggests, are used to stamp or engrave nameplates. Mostly, these are metal nameplates placed on the desk or outside an office.

Embossing machines mark ductile material like plastic and leather with a 3-dimensional image using heat and pressure. This imprints product information on the surface of the material causing permanent deformation. Credit cards are marked with this process, resulting in upraised numbers and letters.

Embossing machines mark ductile material like plastic and leather with a 3-dimensional image using heat and pressure. This imprints product information on the surface of the material causing permanent deformation. Credit cards are marked with this process, resulting in upraised numbers and letters.

Engraving machines are similar, but they are able to cut grooves into much harder surfaces like metals. Jewelry is processed with engraving machines.

Numbering machines are marking devices used to print consecutive numbers on papers, for legal documentation purposes.

Printing machines are also used for marking the surface of flat products. Printing machines generally make ink marks.

Industrial inkjet printers are a type of printing machine. They are larger versions of printers used at home and in the office. Inkjet printers are much faster than many other types of marking machinery but they make temporary marks that can be easily erased and they make use of environmentally hazardous chemicals.

Pad printing machines allow users to print 2D marks on 3D products. These printers use silicone pads to transfer images from a printing plate to a product’s surface.

2.1 COMPONENTS SOME MARKING TOOLS HAVE IN COMMON

| LASER MARKING MACHINE | OTHER MARKING MACHINE |

|---|---|

| The fiber laser: The laser head is the most important component of a laser marking machine on metal. The laser uses optical fiber that generates light and produce a strong beam that can engrave, etch, mark a variety of metals. | Scribers, these are components of any machine that ingrains a mark on material. They are thin shaped and can be made of metal, diamond, or lasers. |

| The laser head: The laser head on your typical fiber laser engraving machine on metal consists of a focusing mirror, focusing lens, nozzle, sensor, and a control system. | Press stamps are plate components used in a stamping machine. They are powered by hydraulic or pneumatic power. |

| CNC system: Fiber laser cutting machines are computer numerically controlled (CNC). The CNC directly controls the machine tool, moderating the movement of the laser head in the X, Y, and Z axes at the same time moderating the power output of the laser to produce markings according to user specifications. | Steel stamps are used with low volume applications. They mark products by hitting or pressing a material, causing an indentation. |

| Hot rubber stamps are very similar to steel stamps, except these plates are made from a heat-resistant rubber or silicone, instead of steel. |

2.2 INNOVATION OF METAL MARKING MACHINE

A need is arising for more customised products among manufacturing and industrial companies. Hence, a rise in demand for marking machines for customization. Customization has gone beyond imprinting figures or signs on metal surfaces. Metal marking has become highly customisable no matter the size of the metal.

Metal marking encompasses various degrees of operations and methods of creating signs and symbols on metal using a machine. Now, the latest innovation in metal marking machines is fiber laser engraver.

Laser engraving machines for metal can be traced to as far back as 1963, we can say that laser technology has come a long way. It can now be used for marking metals. This laser engraving machine for metal uses heat released by a radiated beam to carry out different operations and change the surface of the area being marked. The fiber engraver works thus:

Annealing: A process used to mark on stainless steel which alters the surface colour. The alteration is caused by the heat from the fiber laser machine. The heat causes oxidation of the stainless steel surface, which leads to a colour change.

Engraving: Engraving is a process that involves removing part of the material surface to form a clean, precise and definite mark. However, in this case, the engraving is done by the laser beam on the surface of the metal. The heat from the laser beam melts the surface being engraved.

Removing: Removing process is used to mark coated. When the laser beam touches the surface of the metal, it then removes the coat and exposes the metal beneath.

From these processes, fiber lasers are a great marking performance compared with many other marking equipment.

2.3 FIBER LASER MACHINES AND OTHER MARKING TECHNOLOGIES

Fiber laser marking machines: are more stable since the heat beam is generated within the fiber and no extra optics is required. Marking lasers cool down easily and can produce power up to 1000 watts.

3D Laser Marking: This involves marking logos, texts on a non flat surface. This simply means marking on circular, spherical and other uneven surfaces. This is however achieved with a digitally controlled laser beam from a high speed laser engraving machine with a 3D galvanometer scanner . These laser machines mark fast and efficiently on metals.

Handheld Dot Peen Marking Machine: Dot peen technology came into existence approximately 30 years ago. It works thus: A stylus is controlled by the machine to create marks or dot-like patterns on any desired metal or other material. The stylus has a tip made of diamond or carbide.

In recent times, there are innovations in the dot peen marking technology. For example, there are hand held dot peen. This functions just as a portable laser engraver for metal at the same time retaining the function of the ideal dot peen marking machine. The dot peen marking machine differs from the laser engraving machine for metal in that it does not require a PC before it can mark. It also works without the use of an air compressor.

Handheld Inkjet Printer: The handheld inkjet printer is another innovation in metal marking technology. The inkjet printer has an inbuilt processor whereby users can control both the system and the font you use. The machine uses a real time operating system that does not crash.

2.4 PNEUMATIC MARKING MACHINE

Pneumatic marking machines get the power for marking metals from the energy in the compressed air they use. The pneumatic marking machine needs at least two key components to operate, the compressor and the actuator. Also, a circuit or network of pipes is needed to get air from the compressor to the actuator. Something to switch the air on and off, i.e. the valve and reverse the direction. A pneumatic marking system has an air reservoir where compressed air is stored under pressure.

The pneumatic marking machine integrates mechanical and electronic equipment for marking. It incorporates computer technology, electronic technology and precision technology to mark code, serial number, letter, logo, or other traceable item on materials. The pneumatic technology has a high speed marking hence, operational time is fast.

CHAPTER 3: THE PRINCIPLE OF METAL LASER MARKING MACHINE

Light from a laser marking machine for metal typically has very low divergence. It can travel over great distances or can be focused to a very small spot with a brightness which exceeds that of the sun. As a result of these properties, lasers are used in various applications.

The effect of the laser marking for metals is to expose the deep matter by the evaporation of the surface material. There are 2 accepted principles of laser marking.

Hot working: The high energy density of the laser beam radiates on the surface being processed. The material surface absorbs the laser energy and generates thermal excitation process so that the temperature of the material surface arises resulting in ablation, evaporation, melting, etc.

Cold processing: Cold processing has a high energy (UV) photon that can lead to non-thermal process damage of material. This cold work has a special meaning in the marking process because it is not hot ablated. The cold stripping does not produce thermal damage side effects, therefore, the surface material does not result in thermal damage.

According to laser generators, laser marking machines for metal can be divided into: Fiber laser marking machine, co2 laser marking machine, UV laser marking machine, Mopa laser marking machine, semiconductor pumped laser marking machine, lamp pumped YAG laser machine, green laser marking machine.

Lamp pumped YAG laser machines and semiconductor pumped laser marking machines are no longer in use nowadays because they are outdated. They are big sized and consume high power, they are replaced by fiber laser, co laser, UV laser and green laser.

The fiber laser and co laser belong to “heat working” while UV laser and green laser are “cold processing”.

3.1 LENS FOR MARKING MACHINE

Lens is an important part of a marking machine. Common lenses are 50*50, 110*110, 160*160, 220*220, 300*300, 500*500, etc. There are certain factors that influence the choice of lens for marking on metal. First is the size of marked object and size of marking range. Second is the precision of processing. Thirdly, focal length. When the object is large, the marking range is also enlarged. In other words, when selecting the lens for marking your material, you have to consider; the output of the marking machine, the material, level of graphics and the size of the material.

The more delicate and detailed the graphic is, the smaller the size of lens needed and the thicker the material, the choice of lens should increase. The larger the lens of the laser, the greater the power consumption of the laser. It is a wrong assumption that the larger the lens the better. A large lens increases the scanning area, when the scanning area reaches a certain degree, the light spot diameter becomes enlarged, thus, not sufficiently fine.

3.2. BENEFITS OF LASER MARKING METAL

There are numerous benefits of marking metals with a laser marking machine for metal. The benefits include:

- High-Precision Marking with super quality imprints, even on the delicate interface.

- Durable permanent marking of logo, serial numbers, batch numbers, etc, abrasion-proof, and heat-resistant for long-lasting periods.

- High marking speed is achievable with laser technology.

- Tamper-proof traceability and ID to distinguish parts, components and industry.

- All the laser systems are capable of auto-generating unique QR code and barcodes.

- Laser markings remain durable and outlast after coming into contact with extreme temperatures and fluids.

- Laser tools can mark all types of materials such as stainless steel, plastic, aluminium, copper, and metal.

- Laser technology allows healthy competition among producers, companies and industries.

- Versatile applications. The laser marking machine is useful in many industries such as, aerospace, automotive, electronics, medicals, military, etc.

- No consumables are required. Unlike many other marking technologies, laser machines require no consumables to operate besides electricity. This makes it environmentally friendly.

3.3 FEATURES OF MARKING MACHINE

A typical laser marking machine for metal consists of;

Laser head: The laser head on any fiber laser consists of a focusing mirror, focusing lens, nozzle, sensor and a control system. Its purpose is to optimize the marking function of the laser by focusing its energy accurately and precisely on the material. The laser head can therefore be adjusted to increase or decrease its distance from the target material, changing the light focal length and intensity of the laser beam as it marks the material.

CNC system: Marking machines are Computer Numerically Controlled. The CNC directly controls the machine tool, controlling the movement of the laser head in the X, Y and Z axis , at the same time, moderating the power output of the laser to produce markings according to the desires of the user.

The external pump source: This component guides external energy to the stainless steel laser engraving machine.

The active laser medium: The active laser medium is located on the inside of the laser marking machine for metal. When energy is released to the laser medium, it emits energy in the form of radiation.

The resonator: The active laser medium is located between 2 mirrors. One of these mirrors is a one-way mirror. The radiation of the active laser medium is amplified in the resonator. At the same time, only a certain radiation can leave the resonator through the one-way mirror. This bundled radiation is the laser radiation.

3.4 FUNDAMENTAL PROPERTIES OF LASER

Laser radiation has three fundamental properties, they are:

- Monochromatic. This means that the radiation consists of only one wavelength.

- High coherence and thereby phase coincidence.

- The waves of the laser are approximately parallel due to the coherence

These properties make laser light in modern material processing possible.

CHAPTER 4: HOW TO APPLY THE LASER MARKING MACHINE ON METAL

Laser marking on metal is the process of marking tool parts or workpieces using a laser technology. A laser beam hits the surface of the material, its energy creates a reaction that leaves a permanent mark. The speed, power and focus of the laser beam on the part will lead to different laser processes.

With laser marking, you get to mark directly and permanently on any part of metal. Unlike other marking methods, the laser marking for metal process can be performed at the beginning of the production line. If the marking is performed before treatments like shot blasting and e-coating, you keep high-quality marks throughout the part’s entire lifetime.

A laser marking machine for metal is usually made up of a fiber laser engine, galvanometer and control software. The software also provides the interface to manage multi axis motion systems if required. Frequently, fiber laser marking systems not only mark, but offer laser engraving and laser machining capabilities.

The laser engraver for metal is equipped with software that enables the laser to mark text, graphics, logos, barcodes and data-matrix codes.

FACTORS INFLUENCING THE EFFICIENCY OF LASER MARKING ON METAL

These are the factors that influence the efficiency of the laser marking machine for metal.

- Depth of marking with laser marking machine for metal

If the marking depth on the surface of the material is higher, it is necessary to increase the laser power, which will take up a certain amount of time in marking depth, resulting in the overall marking speed slowing down.

- Spot of focused laser beam in laser marking machine for metal

Through the focus lens, the smaller the spot, the faster it runs because of its small size.

- The size of marking content of laser marking machine for metal

Large content marking will deflect the galvanometer to maximize the satisfaction of marking. But it’s much slower than marking less content.

- Density of label of laser marking machine for metal

Dense marking takes more time than sparse marking. In the same size marking, sparse marking only takes 2 minutes, while dense marking may take 5 minutes. The marking density is higher.

- Fiber laser source power

For laser marking machines for metals, higher power will always improve the efficiency of working.

- Marking amplitude

When the deflection area of the large scale marking mirror is increased, the marking speed of the large scale is slower than that of the small plane. This is why we don’t usually suggest bigger working area lenses, this will reduce the output power because of the longer focus length.

These are the main factors that affect the efficiency of the marking machine.

CHAPTER 5: PRICE AND DURABILITY OF METAL LASER MARKING MACHINE

Choosing the right metal engraving machine price for manufacturing is becoming more important so that manufacturers can trace their products over their complete life cycle. The general thinking among manufacturers is that traceability will improve product quality, ensure that suppliers meet quality standards, prevent production of fake parts, and minimize part recalls. Metal engraving machine price may appear higher than the cost of some other technologies, it is an investment which includes consumables, power use and maintaining costs.

Generally speaking, laser marking machines for metal offer many benefits for direct part marking, because it is faster, more permanent, has a low cost of ownership, uses no consumables, and does not require any further processes to ensure mark durability. Another pricing benefit of a laser is its ability to work with various materials.

5.1. HOW TO CHOOSE THE BEST MARKING MACHINE ON METAL

Laser marking machines for metal are available in various specifications. One size does not fit all. It is important to know things to look out for before investing money in a marking machine. In this section, we give you the factors to consider while buying a laser marking machine for metal.

Core requirement: Focus on the primary reason you are buying a laser marking machine for metal before choosing any laser CNC machine for metal. If your main requirement is to mark different metal materials, buy a single function, specialized marking machine meant for the purpose.

Efficiency: Laser etching machines for metal have commercial applications and it is important to have a number to work with. Even if your current volume requirements are low, take a long-term view and plan for the time when your business will see peaks.

Cost of Ownership: Do not get carried away by an inexpensive sale price of the metal engraver for sale. The marking machine requires maintenance and its cost. A good quality laser marking machine lasts 100,000 hours. The machine that might seem expensive at first will run trouble-free for the number of hours it is meant to work. Eventually, the cost of ownership of a mini laser engraving machine for metal is low compared to machines that require regular maintenance.

Marking Material: Laser marking machines for metal use different technology to mark different materials. Fiber and CO2 based lasers are really popular. However, you need to find out which material you will mostly be working with. Once you know the materials, you can proceed to buy a steel laser marking machine that uses specialized technology to work on it.

Size: Apart from the material, machine size is also a factor in the choice of a small laser engraving machine for metal. The size of the machine’s format should be able to accommodate the materials you are marking.

Replacement Parts: Another factor to consider is if the replacement parts are readily available when the laser engraving machine for aluminium breaks down. Regardless of which device you buy, there is a possibility of a breakdown. There will come a time when replacing some parts of the laser engraving machine for metal will be required no matter how you maintain the machine. Thus, it becomes vital to know whether the replacement parts of the steel laser marking machine are available with ease.

Maintenance: Maintenance is another crucial thing to consider while buying a laser engraving machine for metal. Find out how frequently the maintenance is required for the laser engraving machine and whether you can do it yourself or need to hire an expert. If it is difficult to maintain, your company might need to hire a technician to do the maintenance activity, which can result in additional cost.

5.2 MAINTAINING AND SERVICING LASER MARKING MACHINE

It is important to maintain the laser marking machine for metal to ensure it lasts long.

The first maintenance step is to keep indoor and machine surfaces clean and clean. The indoor environment affects the machine. Regularly check each optical lens for dirt (the duration depends on the working environment), and scrub if there is dirt. Scrubbing method: When cleaning the lens, be very careful. Before cleaning the lens of the sheet metal engraving machine, it is strictly forbidden to arbitrarily change the protection circuit and the main components of the laser marking machine for metal.

Before any maintenance operation, disconnect the power plug. The laser marking machine for metal must be shut down with the key at position “0”.

Keep the inner circulating water clean. Regularly cleaning the laser marking machine water tank and replacing it with deionized water or pure water does not allow other components to be activated before the xenon lamp is ignited to prevent high voltage from entering the damaged component.

Never touch an optic with your fingers as the dirt from your skin can destroy the coatings on the optics. In order to preserve the optical coatings applied to the lenses and mirrors, use the optics paper and the cleaning solution supplied with the laser machine. Do not use alcohol.

When the fiber laser marking machine is working, If the temperature of the surrounding environment exceeds 30 degrees, it is better to switch on the factory air conditioner, if the factory is without an air conditioning system, ensure there is proper ventilation.

If the laser marking machine for metal is in the basement, on the first floor or near the river, if the humidity is too high, but the lens temperature of the laser marking machine for metal is in a very low temperature, condensation is easy to occur, this will seriously affect the normal operation of the portable metal laser engraver. You can increase dryness around the marking machine’s light path.

The air-cooling laser marking machine for metal should always clean the dust on the fan and the optical bench.

You should also pay attention to the internal temperature of the steel marking machine, high temperature will affect the stable operation of the laser power supply.

5.3 ENVIRONMENTAL IMPACTS OF LASER MARKING MACHINE

As more businesses are embracing the “go green” campaign, they are finding that not only can taking a more sustainable approach to manufacturing help the environment, but it can also help their bottom line.

From increasing energy efficiency to reducing waste, there are several things you can do to help make your business more sustainable. One of the best ways to do this is to invest in an environmentally safe laser marking machine for metal and incorporate it into your processes.

With all that power and technology, you would think that laser marking machines for metal systems use large amounts of energy in order to run properly, but this isn’t the case. Laser marking machines for metal systems are designed using low-power components in order to maximize energy efficiency and savings.

No consumables such as chemicals or ink is required when laser marking any metal making it safe for the environment.

Laser marking machines for metal to some manufacturers is a great way for packaging. Not only is this a unique way to package products, but it also eliminates packaging waste and can save money by reducing your business’s costs associated with packaging and branding.

The environmental impact associated with natural branding is significantly reduced compared to traditional packaging, decreasing both the waste produced by discarded packaging as well as CO2 emissions.

5.4 THE BEST CONDITION FOR USING A MARKING MACHINE ON METAL

The following conditions are ideal for our laser marking machine for metal. Room temperature between +15 °C and +25 °C (59°F – 77°F). Relative humidity is between 45% and 65%. You should also protect the device from direct sunlight.

In winter, overnight temperatures may happen to drop below the recommended conditions. This can lead to condensation in the laser tube and thus to damage. In addition, greases and oils can harden, affecting the mechanical parts.

Install a frost guard on the heater to keep the room temperature from falling below the optimal +15 °C (59 °F). You can also warm up the room slowly before using the laser. Do not place the laser too close to the heat source, since the warm air could be drawn in as cooling air, causing the laser to shut down due to overheating.

CONCLUSION

A laser marking machine for metal can be one of the most valuable assets of any company. Ensure you know your machine’s capabilities and your requirements and strike a fine balance between the two. Irrespective of the industry you do business in, there is a customized laser marking solution to suit your exact needs.

Buy a machine that specializes in doing the job you need rather than going for an all-rounder that might struggle at everything. Lastly, a well-maintained, well-serviced machine will last you for many years and the benefits will outweigh the cost of ownership.