Handheld Laser Marker

| Professional Laser Marking and Engraving Solution Configuration Expert in China |

Handheld fiber laser marker is a new technology that every company needs to add to their assets. There is a need to get powerful, accurate marking experience that matches the ever growing needs from clients.

Most of the time, marking companies fails to lay their hands on products that are highly innovative and easy to apply. The handheld fiber laser marking machine can be defined as a machine that does not hesitate to mark any product and maintain quality over a vast range of applications.

It is one of the few cost-effective products that will get the work done regardless of prevailing elements.

Details of Handheld Fiber Laser Marker

| Type: | Handhelder fiber laser marker | ||

| Photo: |  |  | |

| Model: | AT-HF01 | AT-SPHF01 | |

| Laser power: | 20W/30W/50W | 20W/30W/50W | |

| Power supply: | AC220V/50HZ | AC220V/50HZ | |

| Marking speed: | ≤7000mm/s | ≤7000mm/s | |

| Marking area: | 110x110mm | 110x110mm | |

| Lifting stroke: | 280mm | 550mm | |

| Cooling method: | Circulating air cooling | Circulating air cooling | |

| Positioning method: | Red ray positioning | Red ray positioning | |

| Dimensions: | 730x250x650mm | 450x210x415mm | |

| Lifter size: | – | 550x320x680mm | |

- Alldo handheld laser marker is amazing, and it works quickly. They additionally give you enough wavelengths so you play out your work with comfort. In the event that you have a great deal of excess with an exacting cutoff time, our modern laser marking systems can enable you to hit the cutoff time and fill in regardless of the number of customers as could reasonably be expected.

- For improved comfort, they accompany upgraded features that are likewise straightforward, so you won’t need to sit around in the expectation to absorb information. The way that they work at high speeds makes them profoundly dependable and savvy to get set your organization apart from the challenge.

- There is no reason for putting resources into something that wouldn’t last since they accompany sensitive parts. On the off chance that you pick Alldo Tech’s full enclosure laser marker, you will never recognize what it feels like to have a fragile, less sturdy laser marker in your organization.

- They arrive in a solid development that can withstand any kind environment in the midst of operation. Not at all like different models that lose arrangement if marginally prodded, our stamping machines are steady and forceful to serve for as long as 100,000 hours: no upkeep cost, no unexpected glitches. When you have begun to work, there is no halting you.

- Our handheld fiber laser machine works with any advanced programming that your organization may happen to utilize. These incorporate Windows XP, 8, 7, 10. They additionally can bolster 32/64 piece. Be that as it may, they are not perfect with the most recent iOS, though we are attempting to make this a plausibility even to give you more comfort while serving your customers. Our fiber lasers are likewise effectively good with AUTOCAD, CORELDRAW, and PHOTOSHOP organization records.

- They can bolster BMP, DXF, PCX, PLT, and can utilize TTF, and SHX arranges straightforwardly. Alldo Tech works nonstop to guarantee that you utilize the fiber laser stamping machines with any product that your organization utilizes.

- At the point when we state we are here to lessen the creation cost, we would not joke about this. With our laser checking framework, you can for all intents and purposes mark any material and accomplish a similar degree of value over the applications.

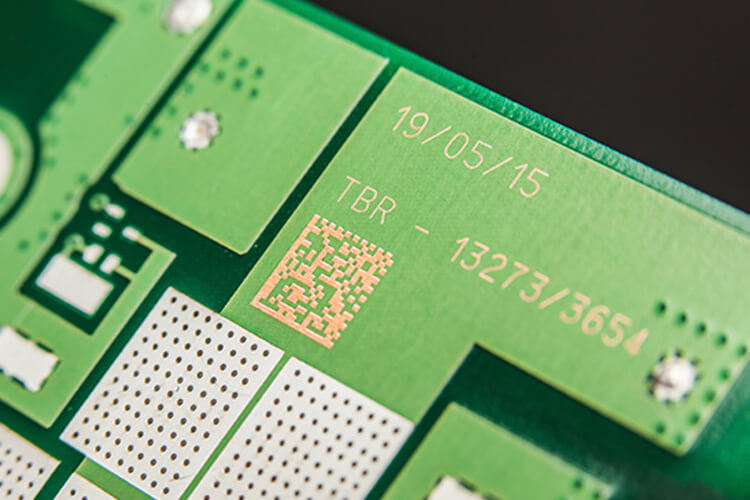

- The items additionally bolster programmed coding, generation date, QR code, standardized tag, sequential number, and much more. Our laser etcher metal stamping framework can be utilized to check gems, kitchenware, vehicle parts, gadgets, hardened steel items, electronic apparatuses, and some more.

- The minimized plan and lightweight of our items make them simple to utilize and store in the work environment. They do accompany significant capacities that probably won’t be accessible in different models. In the event that you have to get familiar with Alldo Tech and possibly submit a request, reach us today.

- We are generally hoping to get notification from our prospects and answer every one of their inquiries expertly. Get our handheld laser marker and appreciate a 1-year full guarantee.

Custom Your Laser Marking System

Application Areas of Handheld Fiber Laser Marking Machine

Laser marking and engraving are the ideal solutions for endless applications, please choose your target area

Marking on Phone

Marking on Tools

Marking on Bearing

Marking on Automotive

Marking on Jewellery

Marking on Switch

Marking on Bolt & Nut

Marking on Knife

Marking on Hub

Marking on Equipment

Marking on Brake Disc

Marking on Connecting Rod

Leave us your materials and industries!

Other Laser Marking Machines

If you are looking for other laser marking machines, then you are in the right place.

| Application: | Glass/wood/leather/plastic/acrylic/paper/PVC, etc. |

| Marking range: | 110x110mm(Customized) |

| Dimensions: | 650x800x1430mm |

| Application: | Almost all metals (gold, silver, copper, iron, stainless steel…), plastics, PVC, etc. |

| Marking range: | 110x110mm(Customized) |

| Dimensions: | 725x250x550mm |

| Application: | Almost all metals (gold, silver, copper, iron, stainless steel…), plastics, PVC, etc. |

| Marking range: | 110x110mm(Customized) |

| Dimensions: | 580x450x780mm |

Handheld Laser Marker

Ultimate Buying Guide

- Chapter 1: Development and Application of Laser in the Marketing Industry

- Chapter 2: Introduction of Fiber Laser Marking Machines on the Market

- Chapter 3: Handheld Laser Marking Applications: Marking and Engraving of Various Materials

- Chapter 4: How to Choose a Suitable Fiber Laser Marking Machine

- Chapter 5: How to Configure Fiber Laser Marking to the Production Line

Chapter 1: Development and Application of Laser in the Marketing Industry

Laser marking system has revolutionized the procedures for marking objects. These objects or substances can be either metal or non-metal. Some great attributes of laser marking is that:

- It produces clean and enduring markings

- The materials that are being marked will not be damaged in the course of marking them. This is different when using flame or other traditional methods to mark things, which can sometimes damage them.

- Laser marking is fast, durable, and stable.

1.1, History of laser development in the field of marking

What is a fiber laser? The laser marking technique comes as a result of the quest for a better, faster, and more sustainable technique for marking objects. The traditional marking methods do not measure up to the demand for an improved, modern way of marking things.

So, the history of laser marking is tied to the advent of the laser technology. Outlined below are some of the inventions before the actual laser technology for marking came into existence:

- Starting from Charles Townes and Arthur Schawlow who invented the “maser” in 1954. The “maser” means microwave amplification by stimulated emission of radiation. This was the beginning of the research that led to the invention of “laser technology”.

- Theodore Maiman in 1960 invented the first ruby laser. This type of laser is now considered to be first viable optical laser in existence.

- Of special note, in 1958, Gordon Gould started working on a laser. However, historians have always considered him as the inventor of the real laser light. Eventually, Gould got a belated patent in 1977 for his invention.

- Western Electric, in 1965, developed the first laser to be crafted for manufacturing. It was primarily used for drilling holes within diamond dies.

And the focused CO2 laser beams for laser cutting were first developed in 1967 by Boeing researchers. This led to the invention of a modern CO2 laser cutter in 1975.

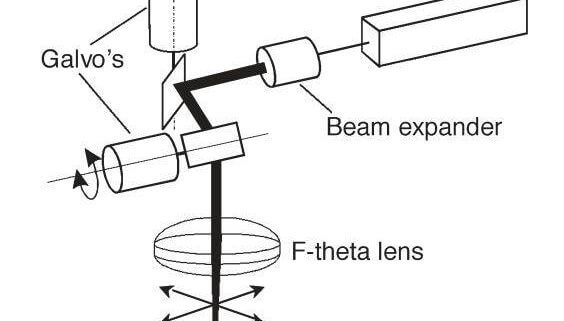

1.2, Principle of fiber laser marking

The principle of fiber laser marking is quite simple and understandable: The fiber laser from the fiber laser marking machine is focused on the objects (metal or non-metal) to be marked, abrade, or engrave. The laser leaves a desirable mark or engraving on the object.

The great things about laser marking are that the marks or engravings will be stable and stay for a long time. It is a safe process which doesn’t damage any part of the objects being marked or engraved.

Chapter 2: Introduction of Fiber Laser Marking Machines on the Market

This section of the guide will introduce you to some great fiber industrial laser marking systems or machines on the market. You will discover their unique features and usefulness.

The major functionalities of our laser marking machines are described in detail below:

- Speed: It is fast and accurately precise when used to mark objects. With the available extra wavelengths, you can easily complete your work on time, irrespective of the number of customers to be served.

- Programming capability:The handheld fiber laser marking machine works with advanced programming, and it can be incorporated with Windows XP, 8, 7, and 10 (for 32/64 bit). Although, not perfectly compatible with iOS systems, it works fine with AUTOCAD, CORELDDRAW, and PHOTOSHOP. The machine’s features can be upgraded from time to time, if necessary.

- Durability:The machine can survive any environment, and its physical parts can withstand any pressure and temperature. They are dependable in spite of working at high speed. The handheld fiber laser marking machine can last for a long time, up to 100, 000 hours in operation.

- Cost-effectiveness: The machine is affordable. It can be operated with minimal plan and costs.

- Additional capabilities: The machine supports BMP, DXF, PCX, PLT, and can use TTF and SHX. It also supports programmed codes, generation of QR codes, dates, standardized tags, sequential numbers, and so on.

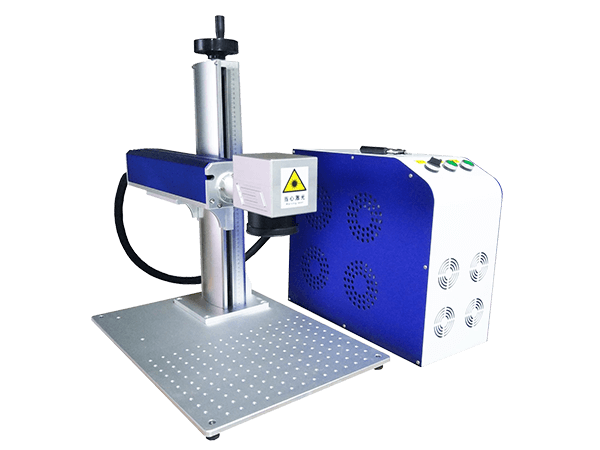

2.1, Handheld fiber laser marking machine

The handheld fiber laser marker, as shown in the picture above, is a compact structure that can be carried easily from one location to another. This handheld metal engraving machine can stand firmly on its feet and hover its engine in place. You don’t need a large working space to install the handheld laser marker. Many users of the handheld fiber laser marking system often offer positive reviews about its admirable performance.

2.2, Portable laser marking machine

According to its name, the portable laser marking machine is truly portable. Its rectangular shape can be slotted into any small space available on the production line. The portable laser maker can easily be operated; so, you don’t need an elaborate training to use the portable fiber laser machine.

2.3, Desktop laser marking machine

The desktop fiber laser engraver or marker looks exactly like a desktop computer, with a monitor attached to the base of the machine. You can easily see the outcomes of its performance on the screen.

2.4, Split laser marking machine

As shown above, the split fiber marking machine is a strong and fast marker or engraver. Its handle is firm and can rotate in different directions.

2.5, Stationary laser marking machine

The Stationary laser marking machine, shown above, is slightly bulky and requires to be situated in one location. Unlike other fiber laser marker, it is placed in one position and operated as such. It stands firmly on the ground and may not be affected by any ground movements.

After reading about the different fiber laser marking machines on the world and their functionalities, you won’t be among those asking the question: What is laser machine?

2.6, Why laser marking machines are the best?

If you are thinking of marking some objects, whether metals or non-metals, the best choice for your business is the laser marking machine. The great things about the laser marking machines include but are not limited to the following benefits:

- Unique technology: Due to its unique technology, which makes it possible for laser light energy to bite deep into any substances through the processes of physical and chemical reactions on the substances, causing the resulting marks on them to be clearly and neatly shown. You cannot compare this approach with the old methodology of marking substances with furnace fire or other heat energy sources. Laser marking machines do not destroy or decolorize the substances they are marking or engraving. This is in sharp contrast to destructive effect furnace flame has on their substances it is marking.

- Large areas of application: The laser marking machines can be applied in a wide range of fields or industries. Take for instance, it can be used to mark or engrave objects such as aluminum, silver, gold, copper, jewelry, as well as plastic, crystal, glass, leather, paper, stone, phone case, automotive parts, watch, electronic components, rubber, and even fabric. Until the invention of the laser marking machines, most of the traditional marking methods will destroy or distort many of the substances listed above.

- Environmentally friendly:The laser marking machines do not pollute the environment. Therefore, your workers will never be exposed to workplace hazards or dangers. The laser marking machines are manufactured so that they can attain high sustainability level.

- Zero or minimal installation and maintenance costs: It won’t cost a fortune to install and maintenance laser marking machines. More so, they do not require a large space to install them. Since it doesn’t need elaborate training before they can be operated, they are comparatively cost-effective. The laser marking machines can be operated by just one person or a few workers; so, you don’t need to invest on hiring, training, and equipping a lot of workers.

Chapter 3: Handheld Laser Marking Applications: Marking and Engraving of Various Materials

What is laser marking and what equipment are required? These are some of the questions prospective customers ask. Here, you will learn about the different laser marking machines and their various applications. Some examples of their usefulness are described below:

3.1, Handheld laser marking for metals

Handheld laser marking titanium machines are applied in the marking and engraving of the following metals:

Laser marking and engraving on stainless steel:

The laser marking machines for stainless steel are designed to handle all manners of marking and engraving on the stainless steel. It is possible to engrave a logo, graphic, QR Code, batch number, photo, drawing, and words on the steel using the laser steel plate engraving machine.

This laser engraving stainless machine works seamlessly with design-making software, and the entire production can be automated. This, undoubtedly, increases the machine’ rate of performance.

Laser marking and engraving on aluminum:

Using the portable metal laser engraver, you can perform three distinct types of laser markings on aluminum: Engraving, ablation (the removal of anodized coating or chemical film from aluminum), and dark marking.

This powder coating laser engraving machine is very good on anodized aluminum; it works or performs the marking by simply removing the film or coating from the aluminum, leaving behind a neatly done marking or engraving.

Laser marking and engraving on gold:

This handheld fiber laser machine makes it easy for jewelry makers load images and design models before they starting marking or engraving on their gold.

This leads to better accuracy and precision. More so, the gold laser marking machines permits annealing, which the modern technique for marking, etching, engraving, and cutting of gold materials. Annealing doesn’t produce any observable change in the gold’s color. This is because the laser marking machine for gold jewelry doesn’t cause any oxidation to occur on the gold material while marking or engraving it.

Laser marking and engraving on silver:

Due its broad use in making several appliances such as tableware, utensils, jewelry, mirror, solar panels, and other stuff, silver is usually required to be marked or engraved. The portable metal engraver machine is able to produce, within seconds, neat and accurate marks, etches, logos, words, vector graphics, special typefaces, and small alphanumeric characters on silver. In addition, it is possible to engrave images, text codes, barcodes, and letters on silver using the ever efficient portable metal engraving machine.

Laser marking and engraving on copper:

The portable engraving machine for metal is specifically useful for marking and engraving copper and the products made from copper, which include wires, circuit boards, and some household materials. Copper has a considerably high thermal conductivity, and this thermal transfer capability makes the laser technology to work perfectly on marking or engraving copper.

This is because the heat produced in the course of marking will soon disappear or go away. For copper with smooth finish and shiny surface, the sheet metal engraving machine can simply be used to anneal, mark, engrave, or etch it. However, those copper with rough or granular surfaces require, in certain situations, dark anneal before they can be marked or engraved.

3.2, Handheld laser marking for industry

The handheld industrial laser marking machines are applied in different industries as explained below. You can also read about their specific laser marking process:

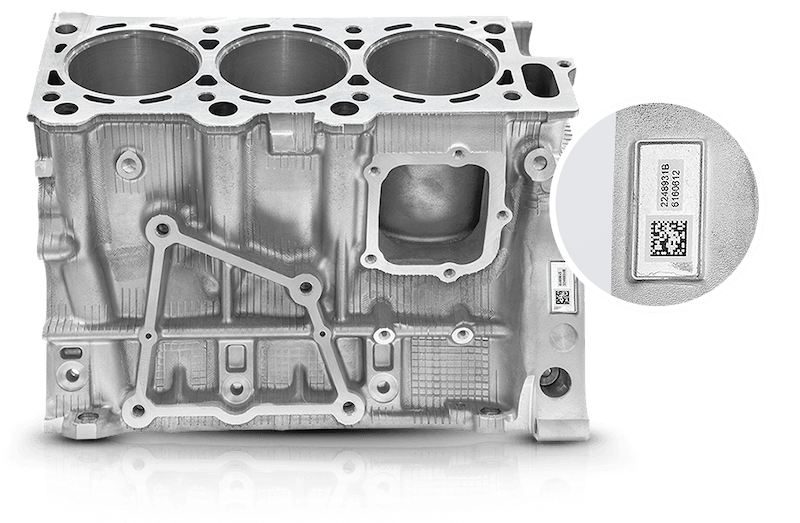

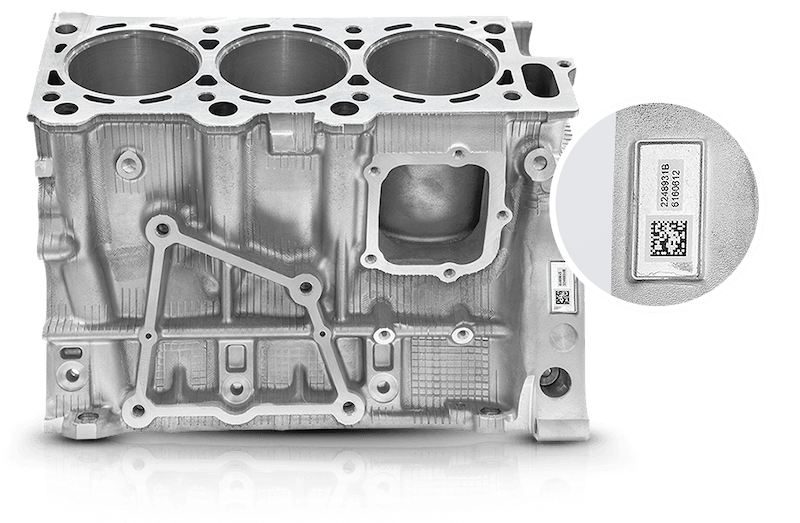

Automotive laser marking:

The automotive industry is a leading utilizer or adopter of the laser marking technology. This is used to mark and engrave alphanumeric number sequences, complex codes, logos, and names of several automotive parts made from metals and non-metals. With the application of the portable laser engraving machine for metals, the automotive industry can trace or keep track of their manufactured parts.

This has helped the industry to maintain quality in all its various operations. And stolen automotive parts can be traced until they are recovered from the thieves. The good news is that the marks left on these parts are tamper proof because they will not fade away anytime soon.

Electronic components marking:

Several of the electronic and semiconductor products such as SMD components are tiny but it is also important that they are marked for easy identification. To achieve this, complex 2D Data Matrix codes are required. These codes can be etched, marked or engraved on these small electronic products using the handheld fiber laser marking machine.

Most importantly, high quality can be maintained if those small semiconductor parts are marked and monitored on the production line. The latest PCB marking machine in town have screens from which the performance of the machines can be monitored.

Jewelry laser engraving:

The jewelry engraving laser machine facilitates the process of engraving all kinds of jewelry. This makes it possible for jewelry makers to creatively personalize the marks, etches, and engravings on their gold and sterling silver jewelry. Utilizing this desktop jewelry engraving machine can also make it possible for the jewelry engraving to be done very fast.

More so, for gold plates that have thickness that ranges from 0 to 1mm can be cut using this jewelry laser marking machine. The engraving will not in any way damage the jewelry, and things like logos, identification texts, serial numbers, and customized images can be engraved on gold and silver.

Watch laser engraving:

The watch industry adopts the use of small laser marking machine to provide some identifications on their watch parts or components that will be used in tracing their watches. Therefore, with a watch mini fiber laser marking machine, it is possible to etch or engrave part numbers, data matrix codes, serial numbers, and decorative marking like logos and brand graphics. These engravings can be administered on a watch’s components, bezels, oscillating weights, crowns, housings, dials, and watch case backs.

Barcode laser marking:

The barcode laser marking device makes it possible to companies to fulfill their legal and standard requirements. They accomplish this by engraving their barcodes and serial numbers on their products for external checking or inspection.

Some of these products with barcodes go through some physical manhandling at the industrial level or shipping ports. In order to assure that the barcodes do not peel off or got erased in the process, it is important that a good marking or engraving approach must be utilized. Hence, barcode laser marking or engraving produce long-lasting barcodes and serial numbers that can stay on products throughout their shelf life.

QR code laser engraving:

Quick Response (QR) Codes are required to identify products and ascertain their quality. A typical QR Code comprises of square display with dark blocks parallel to each other. Anyone can read QR Codes using applications on gadgets such as smartphones (Apple’s iPhone) and iPad. Android smartphones also possess the relevant applications with which QR codes can be read or interpreted. QR code laser engraving machine or any kind of PCB laser marking machine can produce high-quality QR codes at a very fast speed.

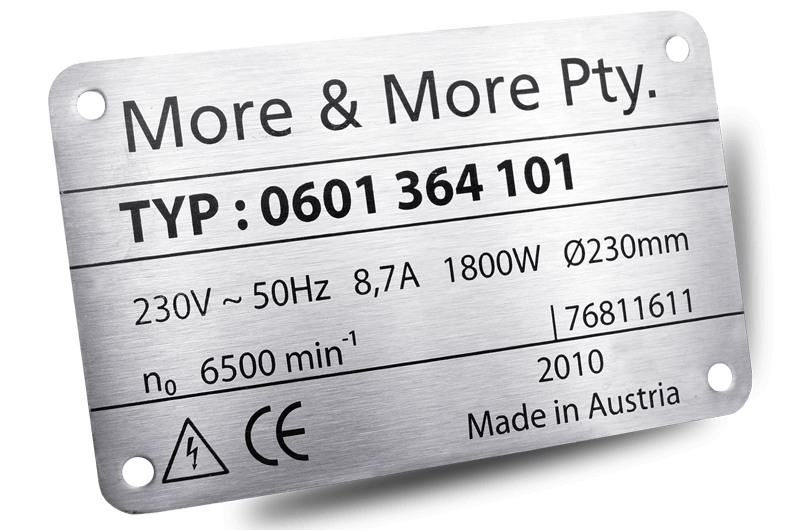

Nameplate engraving:

Nowadays, it is possible to engrave your name or appellation on any surfaces, be it a gold or silver plate, fabric, paper, or leather using a laser engraving machine. The joy of using the color laser marking machine is that it can produce the nameplate in any design, importing graphic and typefaces from the applicable software.

Today, several offices have nameplates that are embossed on gold or silver plates, without any scratch or blemish on them. This proves that the portable laser printing machine can do an accurate job with a few seconds or minutes. Sometimes, for wooden nameplates, handheld wood laser engraver can be used.

If you have purchased a metal nameplate engraving machine from a reputable supplier, you can enjoy at least a year’s warrantee. On the other hand, if you purchased a not-so-good laser nameplate machine, it may affect your rate of production.

NOTE: To work perfectly, all the laser markers must meet the fiber laser marking parameters defined by the manufacturers. Even though all the machines appear to have similar methods of operations, it is essential that the user must follow the applicable laser marking machine working principles. Strictly following the principles, you will never question how does laser marking work.

Handheld fiber laser engravers have several other applications that may not be listed above. For examples, you can use a laser marker:

- To engrave or mark a plastic object such as a plastic cup, bottle, comb, spoon, bucket, and so on. You can obtain a neat, long-lasting mark on these plastic objects. The best approach is to follow the manufacturer’s instructions when utilizing the marking machines. The good news is that once they are engraved, the plastic objects can retain their marks for a very long time.

- To mark a paper or paper materials. Take for instance, you can use the handheld fiber laser marking machine to leave a permanent logo on cardboard, paper certificate, toilet paper, paper napkins, and other paper materials. You will be surprised how great the resulting marks or etches will be on these paper objects. The most interesting aspect of this is that none of the paper materials will suffer any burnt, tear, or wear. They will remain intact and beautiful. Nowadays, you would have seen people embossing golden handwriting on paper. Yes, you can use a fiber laser marking machine to do this also.

- To etch a wooden object. For examples, you can etch a wooden spoon, award, plaque, table, ruler, keyholder, and so on. The great thing about this is that the wooden objects will not be destroyed in the course of the marking. And they can have their marks or etches for a very long time. You can easily etch your name on a wooden keyholder using the handheld laser marking machine.

Chapter 4: How to Choose a Suitable Fiber Laser Marking Machine

This guide will help you make a quick and informed decision about which portable laser marking machine price to choose and purchase for your personal or industrial use. Here are some useful guidelines or checklists for you:

4.1, Power

Pay attention to the power of the fiber marking machine that you would like to buy. The rule of the thumb is that your mini portable fiber laser marking machine should require an average power supply of AC220V/50HZ. Anything more than this will cost you a lot of money to feed power into the machine. The best idea in operating a laser marking machine is to make sure the overall maintenance costs are reduced to the barest minimum.

A 50W fiber laser is capable of doing any job that you have. That is more power than 30 W fiber laser engraver or 20 W fiber laser.

4.2, Marked area

Before buying a laser marking machine, it is advisable to investigate about its marking area—which is the maximum area that the machine can mark when it is being operated. A good machine must have, at least, 110 x110 mm marking area. Anything less than that will make the machine unsuitable for wider applications.

4.3, Marking depth

Choose a laser marking machine that has a deep marking capability. This entails that a shallow marking machine may not produce attractive engravings, etches and marks. Sometimes, the part of the material to be marked may be hidden from the surface; so, a laser marking machine with good marking depth will be able to get the job done.

4.4, Marking material

This is a very important fact: Only choose to buy a laser marking machine that is the best for the type of material that you would like to mark or engraved. There are different types of fiber marking machines, and they come with their different specifications based on their jobs they are expected to performance. Take for instance, it is not proper to purchase a paper laser marking machine and use it to mark harder materials such as copper, gold, or silver. You will save yourself a lot of troubles by buying exactly the kind of laser machine that suits the materials you want to mark or engrave.

4.5, Price

Laser marking machine price is now affordable. So, do not make the mistake of spending a lot of money to acquire one. All you need to do is to contact the right manufacturer and obtain a moderately priced laser marking machine cost. You cannot afford to squander a sizeable part of your annual budget on buying a machine that you could have acquired cheaply. So, set your eyes only on the affordable laser maker price. However, make sure it can deliver the jobs you are purchasing it for. To be honest, the portable fiber laser marking machine price shouldn’t be the priority though, but how efficiently it can perform.

4.6, Maintenance costs

Every company thinks about how to run their operations cost-effectively. Purchasing a good, low-cost laser marking machines from a reputable laser marking machine supplier can help you meet your yearly budgetary allocations. In other words, it won’t be necessary to spend money on maintain the laser machines that have low downtime but high longevity. More so, buy from a manufacturer that offers, at least, one year guarantee (warrantee).

4.7, Durability

Select a laser marking machine that can last for a long time. A good manufacturer utilizes great components to produce their laser engraving portable machines. You can always request for their specific user manual to fully understand the usability of the laser portable engraver you are purchasing. By taking good care of the laser portable engraver device, you can use it for a long time.

Chapter 5: How to Configure Fiber Laser Marking to the Production Line

After purchasing your laser marking and engraving machine, the next thing to do is to think about configuring it for the production line. Irrespective of your industry or nature of your operations, you need to put the laser machine at the right place where its maximum efficiency can be achieved.

5.1 Application of laser marking equipment in production line

As shown in the picture, the laser marking and engraving machine must be put in the right position where it can perform its functions appropriately. Depending on the final expectation of the user, a laser marker can be configured in the middle of the production line or at the end of it.

The marking, engraving, and etching of products, electronic parts, metals, non-metals, plastic, leather, paper, et cetera are done with the laser marking machine. Hence, it must be properly configured so that:

- It can perform well: A laser marking equipment may not function accordingly if it is put in an awkward position or wrong location on the production line. It must be set at the right place where it can have maximum impact or marking depth on the object that it wants to mark.

- It doesn’t wear and tear:Take for instance, if a laser marking machine is situated on the wrong area on the production line, that make cause some pressure that may, in the long term, wear or tear some parts of the laser marker.

- It can work at top speed:It is advisable that you configure your laser marking machine in accordance with the specifications of the laser marking machine manufacturers. Because failure to do this may affect the speed of operation of the machine.

- It can be protected from external elements:Your laser marking machine may not last long if it is exposed to some external elements such as rain, excessive sunshine, and wind. These environmental elements may cause some corrosion or rusting to happen to the machine.

5.2, We can provide the entire production line solution

Not all fiber laser marking machine manufacturers offer this service, but we can provide the entire production line solution for you. Our duties or responsibilities include but are not limited to:

- Advising you about selecting the best laser marking machine china for your industrial use

- Letting you know which is going to match your production requirements before you buy fiber laser marking machine

- Helping you assemble the compact laser marking machine at your factory or workplace

- Identifying the best location or place for the laser marking machine at your factory, after considering factors such as process type, speed, frequency of use, and the length of time required

- Testing the configured laser marking machine on your production line

- Offering the necessary advice based on the results of the configuration

- Providing ongoing support and maintenance for your laser marking machine, since we offer one-year warrantee for our customers worldwide

Get In Touch