UV Laser Marking Machine

Professional UV Laser Marking Machine Manufacturer & Solution Configuration Expert in China

- High photoelectric conversion efficiency, fast speed

- Any non flat material can be engraved and marked

- No installation and training required

- Competitive prices, accept global agents

Apply Our Best Quotation

Alldo UV laser marking machine is useful in marking and engraving many materials like metals, plastics, glass, leather, crystals, specific stones, and many more.

Different industries use this UV laser marking machine and the top industries include cosmetics, medical, and pharmaceutical, etc.

Alldo UV laser marker helps to prevent the act of tampering and counterfeiting in the industries. It helps in lifetime brand protection of the companies.

Some industries use this marker to mark fruit, garments, wood, and ceramic. In the electronic industry, the machine marks computer accessories, phone accessories, chargers, batteries, wires, LED, and some other items.

Alldo Tech UV Laser Marking Machine List

Use this technology to mark any metal and glass materials. It can be applied in both office and industrial production. Its highly competitive marking speed lets you get the job done in the shortest time and with the utmost quality.

Apply Our Best Quotation

How to choose a model?

Application Areas of UV Laser Marking Machine

Laser marking and engraving are the ideal solutions for endless applications, please choose your target area

Marking on Plastic

Marking on Crystal

Marking on PVC

Marking on Glass

Marking on Switch

Marking on Medical

Marking on Awards

Marking on Plastic Card

Leave us your materials and industries!

UV Laser Marking Machine Ultimate Buying Guide

- Chapter 1: Advancement and Use of Lasers in Various Marking Industries

- Chapter 2: Types of UV Laser Marking Machine Alldo Tech Provides to Customers

- Chapter 3: UV Laser Machine for Marking and Engraving Different Material Surfaces

- Chapter 4: Points to Consider before Choosing a UV Laser Marking Machine

- Chapter 5: How to Setup Laser Marking Machine for Productions

Chapter 1: Advancement and Use of Lasers in Various Marking Industries

1.1, History of UV laser Marking Machine Development

In the early 1970s, most ultraviolet (UV) applications relied primarily on UV lamps. The development of the excimer and solid-state UV lasers, however, gave researchers access to higher-power UV radiation. Lasers rapidly became the enabling technology for many new applications. High-growth markets including semiconductor, medical, and micromachining now rely on excimer and solid-state UV lasers.

With the continuous development of UV Laser Marking Machine, the high-power ultraviolet lasers has spawned many new applications, which cannot be achieved by low-power lasers. For example, a smaller laser engraves information on the objects, which is slow in printing and inhomogeneous in colour. It can not satisfy the industrial mass production capacity. The application of UV laser marking machines in many industries is expanding, because the UV laser marking machine could get a perfect marking on the nonmetal objects, better than any other laser types.

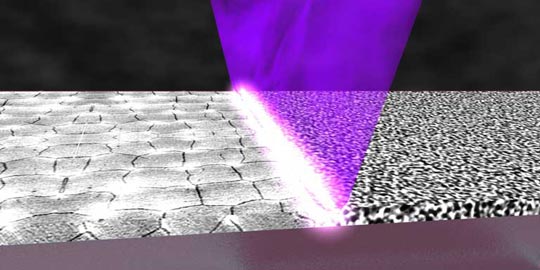

However, the UV laser marking machine is a series of laser marking machines, but it is developed by a 355nm ultraviolet laser. The machine adopts three order intracavity frequency doubling technology. Compared with the infrared laser, 355 UV focal spot is small, can largely reduce the material mechanical deformation and processing of small thermal effect, because it is mainly used for ultra fine marking and carving, especially suitable for food and pharmaceutical packaging materials, marking holes, high-speed glass material and the division of wafer complex graphics and other applications.

In the international advanced technology, high energy ultraviolet photons direct damage to the molecular bond nonmetal material surfaces, the molecules from the object, this way does not produce high heat, ultraviolet laser beam machining and minimal aggregation has almost no heat effect, so it is called cold processing, it is suitable for the special nonmetal materials.

The main features of the UV laser marking machine are high electro-optical conversion rate, high beam quality, very small spot size, and ultra-fine marking. The nonlinear crystal has a long service life, very stable operation, high accuracy positioning and high efficiency working. The modular design is easy to install and maintain, the machine overall is smaller and compact, working smoothly and stable. The UV laser marking is perfect quality, because the heat-affected zone is small, there is no thermal effect, the material will not get deformed and not burnt.

1.2, Principle of UV Laser Marking Machine

The ultraviolet laser marking machine is a series of laser marking machines. Therefore, the principles are similar to those of laser marking machines. They are permanently marked by laser beams on various material surfaces. The effect of marking is to expose deep matter through the evaporation of surface matter, or to engrave traces through the chemical and physical changes of surface matter caused by light energy, or to burn out some substances by optical energy, and to display the patterns and characters needed to engrave.

The UV laser marking machine is mainly based on its unique low-power laser beam, which is especially suitable for high-end market demand for ultra-fine processing, such as cosmetics, pharmaceuticals, medical equipment, and polymer materials. Used for marking and surface treatment of various glass, liquid crystal screen, plasma screen, plastic, textile, sheet, ceramic, monocrystalline silicon wafer, grain, sapphire, polymer, building materials, film and other materials. It is also important to know that the UV laser marking machine can mark some metals but not as deep as it would appear on a metal marked with a fiber laser machine.

1.3, Component Parts of a UV Laser Machine

Below are the main components of a UV laser marking machine.

- Laser source- The UV laser marking machine adopts a wavelength of 355nm ultraviolet laser which is a kind of cold light. The laser source is responsible for feeding the laser beam with the adequate power it needs for marking on materials.

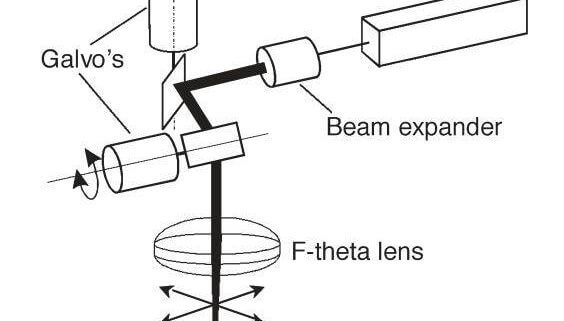

- Laser marking head- The laser marking head consists of two scan mirrors, two galvanometers, drive cards, a set of softwares and DC power supply.

- F-theta lens- The F-theta lens has a laser spot position linearly proportional to the scan angle, which offers exceptional durability and enables users to perform high precision laser material processing.

- Control board and marking software- The control board contains all buttons and switches that are needed to control the laser marking machine.

- Computer- The computer contains all softwares that is required for laser marking processes. It supports AUTOCAD, CORELDRAW, PHOTOSHOP, etc.

- Lifting Piller- The lifting pillar supports the laser marking head and sometimes the computer.

- 2D work table- The working table allows optimal configuration for all marking and engraving applications.

- Power supply- UV laser power supply can be 3w, 5w or 8w with a power supply of AC220V/50HZ.

- Water cooling unit- This part of the UV laser machine is responsible for regulating the laser machine temperature.

Chapter 2: Types of UV Laser Marking Machine Alldo Tech Provides to Customers

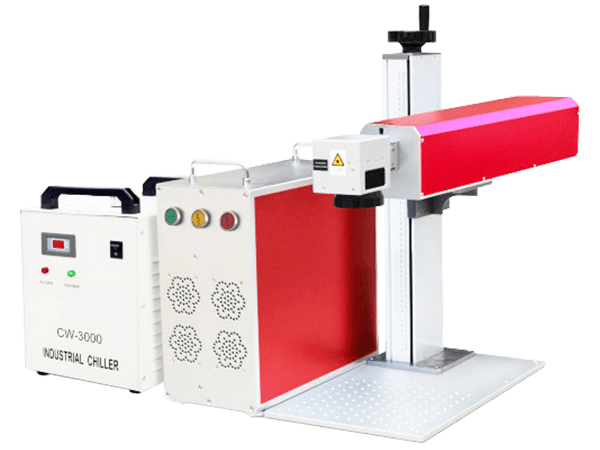

2.1, Stationary UV Laser Marking Machine

The stationary UV laser marking machine is an economic equipment designed to make high precision marks on certain materials such as; plastic products, electronic parts, common household appliances, PCB, glass, acrylic, certain stones, wood, garments, etc. The stationary UV laser marking machine carries less heat energy with a beam. So that materials like plastics will not be affected by heat. The marking effect is fine and can be repeatedly processed, and the high-precision and tiny spot ensures the perfect marking result, and there is no contact marking, so the marking effect is permanent.

The stationary UV laser marking machine does not require heavy power due to the fact that the laser beam does not generate heat for marking. The power requirement of our stationary UV laser marking machine is between 3w to 8w. The marking speed of the stationary UV laser marking machine is nothing less than 7000mm/s, which means that marking is done very fast which makes it suitable for a busy and demanding production industry. Many industries apply the UV laser technology on their nonmetal products for the sole purpose of identification, traceability and creative design.

The stationary UV laser has a service life of 100,000 hours with a marking area that measures up to 110x110mm. The cooling method is usually through a circulating water cooling system unit that maintains the marking temperature of the UV laser marking machine.

The structural design of the stationary UV laser machine can be likened to a standard washing machine in terms of height, approximately 85cm high. The machine dimension is 677x750x1430mm. The height is always convenient for adult height operation. The lifting pillar is solidly attached to the top and this holds the laser lens and computer. Also on the UV laser machine surface is the control panel and the marking area on which materials will be placed for marking and engraving.

The water cooling system comes separately, that is, it is not attached to the main laser machine, with its height almost half of the stationary UV laser machine itself. The air cooling system also has its control switch.

2.2, Split UV Laser Marking Machine

Alldo Tech split UV laser marking machine is made to mark various inscriptions on acrylic, different types of plastics (PVC, PCB), certain metals, etc. The split UV laser marking machine size is more portable compared to the stationary UV laser machine; thereby suitable for small and large marking needs.

The split UV laser marking machine adopts a high-quality and imported ultraviolet laser generator. The ultra-small focusing spot of 355nm ultraviolet light can ensure hyperfine marking and the minimum marking character can be accurate to 0.2mm. During the period of operating, the machine’s heat affected zone is inappreciable and the materials can still be nondeformable. Accordingly, the system is suitable for processing those materials that have big reactions to thermal radiation.

The UV laser marking machine adds a portable design to the traditional split body, easy to carry and operate.

The laser power is between 3w and 8w with a marking speed of 7000mm per second and a marking range of 110mmx110mm. The cooling mode of the split UV laser is through a water cooling system.

The split laser marking machine is a more compact design that is easily movable due to its structure. The split UV laser will require an elevated object due to machine height. The marking area is easily noticeable, attached on the marking area is the lifting pillar that has the laser lens attached to it. Exactly by the side of the marking area is the control system (can be compared to a desktop CPU) and switches. The water cooling system is separately designed with almost the same height with the split laser control system. The power cabinet size is 450x210x415mm.

Chapter 3: UV Laser Machine for Marking and Engraving Different Material Surfaces

3.1, UV Laser Marking Machine for Plastic

The most common processes for laser marking on plastics are carbonization, colour change, foaming and removing.

Foaming– Foaming leaves a tangible mark on the plastics. It can be seen as laser-induced boiling, which melts the surface. Due to the rapid cooling, bubbles are encapsulated in the material. These bubbles leave a positive mark, which is tangible.

The laser works on a low power level and longer pulses. Foaming works on all polymers, but also on some metals. Depending on the material, the mark can be light or dark.

Carbonization- Carbonizing enables strong contrasts on bright surfaces. During the carbonizing process the laser heats up the surface of the material (minimum 100° C) and oxygen, hydrogen or a combination of both gases is emitted. What’s left is a darkened area with higher carbon concentration.

The laser works with lower energy, which leads to slightly longer marking times compared to other processes. Carbonizing can be used for polymers or bio-polymers. Since carbonizing always leads to dark marks, the contrast on dark materials will be rather minimal.

Colour change- Colour change on plastic guarantees highest legibility. Laser marking with colour change is basically an electrical process, which reorders the macromolecules (by changing the direction). No material is removed, but partial foaming is possible.

The plastic engraving machine works with a maximum pulse rate but low energy per pulse. Otherwise material would be removed or foaming might occur. Colour change works on plastics and the change of colour can be bright or dark. Most colour changes are dark.

Removing- Removing is used with multilayer plastics (laminates). During the removal process the laser beam removes the top layers, which had been applied to the base material. This results in colour contrasts due to colour differences in the layers.

3.2, UV Laser Engraving on Crystal

Crystals are part of the materials the UV laser marking machine can engrave upon. Crystals are often used for awards and trophies, they are also used as materials for souvenirs, hence, the need to engrave on crystals. The UV laser marking machines are built with a quality galvanometer head and a laser UV power source, ensuring high quality and stability at the time of engraving with high speed without damaging the material surface.

There are three steps to engraving a 3D crystal:

Step 1: Convert the image, logo or texts you want to engrave to a 3D series of points that the UV laser engraving machine uses as a stencil for engraving.

Step 2: Align the crystal you are engraving. Proper alignment ensures an excellent engraving result.

Step 3: The crystal is then set for engraving. The UV laser engraves each point individually and pulsed. Each pulse creates a tiny hole in the crystal. The energy at the end of the laser is what causes the distortion, therefore, allowing carving inside the crystal without damage.

3.3, UV Laser Marking for PVC

PVC is one of the common materials in our life, usually it is used as water pipes, control panels and electric cases. With a UV laser marking machine, we can make permanent colours on the surface; the marking will not damage the material surface as it is very light.

Laser marking of PVC produces high contrast marking on any colour. The process is also very fast and efficient. However, it is important to consider that the polyvinyl chloride is a polymer composed of chlorine. During the photodecomposition of the material, it undergoes dechlorination producing the emission of gas.

3.4, UV Laser Engraving on Glass

Glass engraving machines can mark 3D glass with the subsurface engraving or surface engraving using the UltraViolet laser technology. Letters, digits, and machine readable codes are transferred into or unto glass by a UV laser beam in just a few seconds. The laser markings cannot be removed or rubbed off.

During engraving the intense laser beam creates micro-cracks on the substrate and bypassing the marking area creates a nice “field of micro-cracks” that reflects light and appears as a beautiful sand-blasted matt finish that you see in the final artifact. The actual mechanism of laser interaction with the material is rather complex. It depends on the type of laser as well as the conditions of radiation, such as its power, wavelength, focusing, frequency of pulses and more. This is so small that the integrity of the substrate is not compromised; yet big enough to create the visual effect of a matt finish.

3.5, UV Laser Engraving on Awards and Trophies

An award is a symbol of recognition and hardwork, perseverance and dedication. Crystals, glass, acrylic and wood are common materials used for making awards and trophies. Virtually any design including texts, logos, images or photos can be engraved using a UV laser marking machine. Engraving awards and trophies is a fast and noncontact process where several pieces of information that needs to be engraved are done with high precision.

3.6, UV Laser Marking on Acrylic

Acrylic is a clear, rigid and unbreakable UV resistant plastic material that belongs in the thermoplastic family. Acrylic engraving is a way of adding unique and fascinating features on acrylic materials.

When the acrylic meets the laser beam, the resultant product has an attractive look. Before engraving acrylic, ensure you have the correct layout of the image. That is, having the engraving on the right position.

Chapter 4: Points to Consider before Choosing a UV Laser Marking Machine

4.1, Power Capacity

Power is an important point to consider when choosing a UV laser marking machine for your productions. The UV laser marking machine generally does not require too much power; therefore, with the laser power capacity of 3w, 5w or 8w. The power capacity will also determine the speed at which the UV laser engraves.

4.2, Marked area

Before purchasing a UV laser marking machine, it is necessary to know the marking or working area, which can also help to decide the power source. The optic laser head works like a magnifying glass and the closer the object is, the more diffuse is the focus point of the light. On the contrary, if the magnifying glass is far away, the light is scattered and it also fails to engrave clearly and powerfully.

This means that some machines cannot have a working area more than 10x10cm because the head needs to have a focus space between the lens and working table. Which implies that you need to check the UV laser model that allows you to engrave on all your products.

You must also consider if the machine has an automatic change, which can streamline the finishing sequence of the project, optimizing the production time.

4.3, Marking depth

The marking depth usually varies according to material type. Engraving on different nonmetal materials can reach a depth of below 0.6mm exactly or a little above 0.6mm. For example, awards and trophies can be marked between 0.001-0.125mm.

4.4, Marking material

First of all, you must know the materials you want to mark or engrave before choosing your laser machine. Laser machines are designed to work optimally with a specific type of material, and you must prepare a design and a material that you will use to make a sample with different machines and parameters. That way, you can compare results in relation to power, speed, engraving, resolution, etc. The common materials that the UV laser marking machine marks include; glass, certain metals, plastic, acrylic, etc

4.5, Cost of UV laser Machine

Your budget for the purchase is going to determine the kind of laser machine you will buy. Though the price of the laser engraving machine will not necessarily dictate the quality of it, budget is one of the things to be considered while making a purchase decision. A standard purchasing price gives an excellent laser performance and a long service life. Generally, the UV laser prices should not stop you from getting the best UV laser marking machine because there are cheap UV laser machines that you can afford.

4.6, Maintenance costs

The UV laser marking machine requires no rigorous maintenance. To ensure a longer lasting service life of UV laser marking machines, it requires cleaning after each use to get rid of dust and particles from the engraving process. The water cooling unit should also be checked before each marking and engraving operations.

4.7, Durability

In terms of wavelength, UV laser marking machines have shorter wavelengths than visible wavelength, so it is not visible to the naked eye. Although you can not see these laser beams, it is these short wavelengths that make the UV laser to focus more precisely, and thus maintain excellent positioning accuracy while producing extremely fine characters or images on materials.

4.8, Focal Length

When choosing a fiber optic laser, you must have in mind the focal length. The focal length is due to two variables; the first is power of the power source and the second is the working area of the lens. These must be combined correctly to get a deep and precise engraving. A low power laser with a large engraving area will have a weak and shallow engraving.

4.9, Pulse Resolution

The resolution of the machine has two factors; the frequency and the maximum resolution. The higher the frequency spectrum, the greater the engraving capacity, therefore, the resolution and accuracy is going to be much better, the quality of engraving sharp and better in small details.

4.10, Engraving Speed

The engraving speed is relative to the power of the optical power source, the more the power, the more the marking and engraving speed. For example, 10w power can achieve 4000mm per second engraving can only achieve that speed using a maximum engraving power with an excellent precision marking. Therefore, if you use a 30w laser, it can engrave a depth of 0.3mm at a speed higher than 4000mm per second with a decent engraving result.

It simply means that the higher the power, the higher the engraving speed.

4.11, Warranty and After-sales Services

After sales service will define the quality of the machine you purchase. Our standard technology has more than one year warranty according to the FDA and CE standards. Although UV laser marking machines do not require heavy maintenance, it is very common to need a part replacement or change over the course of use. This is why you must choose a machine with good warranty coverage just like we have in Alldo Tech. We also provide after-sales services, whereby we put you through the use of the laser machine and to resolve incidents.

Chapter 5: How to Setup Laser Marking Machine for Productions

5.1 Uses of UV Laser Marking Machine for Production

The UV laser marking machine is no doubt widely used across various industries due to their outstanding features and advantages to businesses.

Industries such as pharmaceutical, cosmetics, medical, souvenir, kitchenwares, etc make use of the UV laser marking machines to prevent tampering and counterfeiting, helping to ensure lifetime brand protection and traceability. Below are the industries that make use of the UV laser marking machine:

- Souvenir and branding- Souvenir industries make use of various materials like 3D glass and crystal to make souvenir items. The souvenir industry is a fast growing and competitive industry because of the creativeness it adopts. As a result of this, the 3D laser glass engraving machine is used on materials that makes them unique. Markings and engravings appear on souvenirs are of high quality and non erasable. 3D crystals are commonly used as souvenirs because 3D designs can be generated inside. People are now opting for the 3D crystal engraving when it comes to souvenirs because it is trendy in recent times.

- Glass and glassware industry: Glass provides a wide range of applications. 3D laser glass engraving machine is used in glassware production to customize items such as wine glass, wine bottles, beer glass, etc.Wine glasses are marked with logos and other decorative elements with a UV laser marking machine to give an aesthetic appeal to glasswares. Glasswares are also found in some laboratory equipment.

Glass equipment found in laboratories include; test tubes, beakers, pipette, petri dish, etc. Measurement gauges are often marked on laboratory glass instruments for adequate research practices.

5.2, We Provide the Solution to all Marking and Engraving UV Laser Needs

The sole aim of all production industries is to keep up with the supply of high demanding products, having in mind that inability to meet up with demands can lead to overtaking by competitors in the same industry. This is one of Alldo Tech’s aims to provide high quality and very fast UV laser marking technology that helps you to mark a vast range of your products within a short time length. Marks made on your products are indelible, therefore, you don’t have to remark product parts despite going through a harsh production environment.

We provide a total solution for brand protection. Many companies are faced with the challenge of their original product being fabricated and sold in the open markets. This occurs when company products are not properly marked for traceability. Through our UV laser equipment, brand protection is certain. The original items can be easily recognised and distinguishable either through barcodes or serial numbers marked on your products.

We proffer a long service life of UV laser marking machines. The UV laser marking machine is your company asset and should service you for a long time. Our UV laser engraving machine lasts for a long time (100,000 hours).

Our UV laser marking machine makes high precision marks on your products that are not erasable. Traditional marking ink fades or gets washed away whenever contact is made with water or other harsh conditions.

5.3, Conclusion

Purchasing a UV laser marking machine requires a careful and conscious decision. Understanding that the UV laser marking machine is an advanced and suitable technology for marking delicate and fragile material such as glass, making a wrong choice of laser marking machine has a way of impacting your business negatively. In order to make the right choice of laser marking machine for your business, we guide you through the process of purchase, instalment and use.

Our UV laser marking machine continuously serves your business for long hours each day, and you can guarantee high quality marks on your products. The UV laser is easy to use and maintenance free.

Get In Touch