Mini Fiber Laser Marking Machine

| Professional Laser Marking and Engraving Solution Configuration Expert in China |

The mini fiber laser marking machine is a new technology that is designed to make permanent marks of logos, serial numbers, barcodes, etc on materials such as gold, silver, copper, iron, stainless steel and nonmetal surfaces. The mini fiber laser marking machine is a compact size design that already has an inbuilt computer. Marking production materials does not require a configuration of any other computer.

The high speed of 7000mm/s makes product identification and traceability fast and easy. The

operation is of high performance with a reliable control system. The power consumption of the mini fiber laser marking machine is low, only 0.5kW/h.

Details of Mini Fiber Laser Marking Machine

| Type: | Mini integrated fiber laser |

| Model: | AT-MF01 |

| Laser power: | 20W/30W/50W |

| Power supply: | AC220V/50HZ |

| Marking speed: | ≤7000mm/s |

| Marking area: | 110x110mm |

| Lifting stroke: | 550mm |

| Cooling method: | Circulating air cooling |

| Auxiliary control | PLC touch screen |

| Positioning method: | Red ray positioning |

| Computer System: | Chinese / English System |

| Accessibility: | 3 red ray assisted focus |

| Dimensions: | 588x538x300mm |

| Weight | 28kg |

- The inbuilt computer of the mini fiber laser marking machine makes designing and direct marking of logos and other symbols on different metal and nonmetal surfaces easy. There is absolutely no need for an external computer.

- The compact structure of the mini fiber laser machine makes it very easy to move about (weighing about 70kg) and at the same time, it does not take space.

- The mini fiber laser machine has a lifespan that can work up to 100,000 hours, this will yield a huge profit for you over the course of use.

- The mini fiber laser marking machine is applicable to mark products of various industries and components of automobile parts, electronic, mechanical parts, instruments, hardware tools, plastics, etc.

- The mini fiber laser machine has a marking speed of 7000mm/s can mark on materials at a fast rate and marks are permanent on whatever surface the laser beam comes in contact with.

- The marking depth of the mini fiber marking machine is 0.01mm, therefore making it deep enough to prevent fading overtime.

- The small size of the fiber marking machine makes the power consumption low. The whole power consumption is below 500W. The electro-optic conversation rate is up to 30%. Power consumption is lowered by 3-10 times.

- The mini fiber marking machine is environmentally friendly and energy saving.

- The marking machine has an air cooling system that can run for 24 hours. The air cooling system ensures the mini fiber marking machine does not overheat for long hours of marking.

Custom Your Laser Marking System

Application Areas of Mini Fiber Laser Marking Machine

Laser marking and engraving are the ideal solutions for endless applications, please choose your target area

Marking on Jewellery

Marking on Phone

Marking on Tools

Marking on Bearing

Marking on Switch

Marking on Gear

Marking on Bolt & Nut

Marking on Knife

Leave us your materials and industries!

Other Laser Marking Machines

If you are looking for other laser marking machines, then you are in the right place.

| Application: | Almost all metals (gold, silver, copper, iron, stainless steel…), plastics, PVC, etc. |

| Marking range: | 110x110mm(Customized) |

| Dimensions: | 800x430x750mm |

| Application: | Almost all metals (gold, silver, copper, iron, stainless steel…), plastics, PVC, etc. |

| Marking range: | 110x110mm(Customized) |

| Dimensions: | 730x250x650mm |

| Application: | Almost all metals (gold, silver, copper, iron, stainless steel…), plastics, PVC, etc. |

| Marking range: | 110x110mm(Customized) |

| Dimensions: | 580x450x780mm |

Mini Fiber Laser Marking Machine

Ultimate Buying Guide

- Chapter 1: Development and Application of Laser in the Marking Industry

- Chapter 2: Introduction of Fiber Laser Marking Machine on the Market

- Chapter 3: Fiber Laser Marking Machine Application: Marking and Engraving of Various Materials

- Chapter 4: How to Choose A Suitable Fiber Laser Marking Machine

- Chapter 5: How to Configure Fiber Laser Marking to the Production Line

Chapter 1: Development and Application of Laser in the Marking Industry

1.1, History of laser development in the field of marking

Lasers have been around in one form or the other ever since the 1950s, and their invention can be traced back to Einstein’s theory of light emission in 1916.

Before the development of lasers, “masers” were developed. This technology was close to, but not exactly the same as the laser. The maser used ammonia gas and microwave radiation rather than visible light. Four years later, lasers were developed which would use infrared and a visible spectrum of light.

The first ruby laser, which was widely considered to be the first viable optical laser was invented by Theodore Maiman.

The first laser was designed for manufacturing was developed by Western Electric for the purpose of drilling holes within diamond dies.

CO2 lasers were first developed in 1967 and the focused CO2 laser beam for cutting. A laser (CO2 variety) is basically a tube with mirrors at both ends, filled with a mixture of gases ( mostly nitrogen, helium and carbon dioxide). When electric energy is applied to the glass filled tube, it excites the molecules, which vibrates and emits light that bounces back and forth between the two mirrors.

Another form of laser that was developed is the YAG laser. The YAG laser was developed to use a rod of yttrium aluminium garnet and a small amount of a rare element called neodymium to create light. YAG lasers are used for marking metals as well as non metals, and they work well with items that have rough surfaces.

When lasers were invented, they were not immediately adopted by the engraving industry. Will Dahlgren’s computerized engraving machine also changed the landscape for the laser manufacturing industries.

All these developments paved the way for laser marking and laser engraving for a wide range of industries. Laser marking is not the only form of product marking, but laser marking outperforms other methods such as dot peen, electrochemical and inkjet. All these forms of marking including laser marking have greatly impacted the advent of barcodes and serial numbers. Without these codes, product marking would be more limited and certain forms of marking might not have been developed.

1.2, Principle of fiber laser marking

The main work principle of the fiber laser marking machine is that the fiber laser beam marks on the surface of different materials made of metals and nonmetals, in the forms of various patterns, logos and some other tags. These markings are permanent.The effect of marking is to expose the deep matter by the evaporation of the surface material.

A laser beam begins as an atom that is stimulated to release particles of light. This light can be concentrated and directed toward a laser marking area. The energy that is released is measured in wavelength or nanometers (NM). The fiber laser operates at 1070NM, delivering significantly high power to mark materials.

The fiber laser marking works by using a focused beam of light to mark the surface of a material. When the beam interacts with the surface of the material, it alters the material’s properties and appearance. This concentrate beam targets only a specified area, allowing the laser marking machine to create precise, high-quality, high-contrast marks that are easy to read or scan on any surface. This feature makes laser marking ideal for applications where accuracy and permanency are required.

Chapter 2: Introduction of Fiber Laser Marking Machine on the Market

2.1, Mini fiber laser marking machine

The mini fiber laser marking machine adopts a pulsed fiber laser beam to mark the surface of various materials permanently. The effect of marking with a mini fiber laser marking machine is to expose the deep layer material by evaporation of the surface layer material caused by light energy to show the desired text, barcode and other graphics. A mini fiber laser wavelength is 1060NM.

The mini fiber laser marking machine belongs to the group solid-state lasers. It does not require direct contact with the surface material, so the marked material can retain its strength even after the marking function.

Mini fiber lasers can mark on different types of metals and nonmetallic materials, such as ceramics, plastics (like ABS, PVC, PP and PE) as well as metal materials including stainless steel silver, gold, copper, aluminium, brass, bronze, carbide, etc.

The mini fiber laser marking machine has been widely accepted in today’s market due to the following benefits:

- The mini fiber laser marking machine does not make use of consumables, fuel, gas or chemicals.

- The life span of the fiber source is 100,00 hours, so it is a low cost fiber laser machine.

- The small size (compact size) of the fiber laser marking machine makes it the most sought after laser machine because it does not require large space and the maintenance of the machine is simple and easy. The compact size of the fiber laser is ideal for small factories, workshops because they always want to avoid machines and equipment that take up space.

- The mini sized fiber laser marking machine has an inbuilt computer that comes with the software programme required for preparing the text, logo, bar codes, etc that needs to be marked on materials.

- The cooling system of this mini fiber laser marking machine is air cooling, not water chiller. It makes fiber laser marking more convenient.

- There is no harsh chemical caused by the marking process, this makes the mini fiber laser marking machine safe to use and environmentally friendly.

- Several industries can adopt the mini fiber laser marking machine to mark their product for identification and easy traceability. Such industries include; aerospace, automotive, dental, electronics, jewelry, medical, solar, semiconductor, etc, also make use of the small fiber laser marking machine.

Mini fiber laser marking machines can satisfy high marking requirements on depth, smoothness and fineness. The marking performance of the mini fiber laser marking machine makes it stand out among other types of laser machines, due to its consistent marking quality with a high speed of 7000mm/s; 2 times higher than traditional marking.

2.2, Desktop fiber laser marking machine

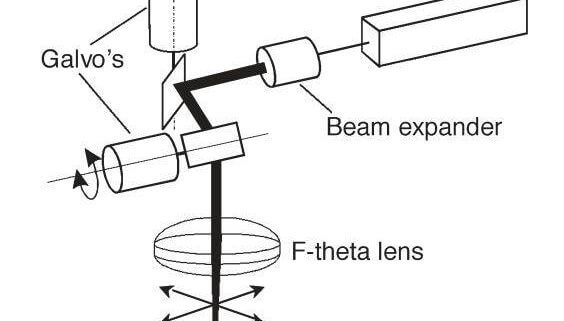

Desktop fiber laser marking machine for metal and nonmetal is the third generation class laser marking system. It adopts an optical fiber laser to output laser and realizes marking function through a high speed scanning galvanometer system.

The desktop fiber laser marking machine has an imported galvo scanner that is designed for superior and 20% faster marking performance. This desktop fiber laser machine is used for making areas of 100mm x 100mm. It marks a wide range of materials at less than or equal to 0.1mm. The desktop fiber laser marking machine features high electro optic conversion efficiency, air cooling, small size, smoothness and fine detail.

Desktop fiber laser marking machines have simple structures and greatly reduce failure rates due to its structure as it comes with a computer. This computer comes with the softwares that enables users to design and control any image, barcodes or texts they are marking on objects. The desktop fiber laser components are: the optic lens, galvanometer, laser source, control card, power system, computer, up right and the desktop itself.

The desktop design makes it applicable for use in many industries. They are mostly used for large and small scale marking in automotive, electronics, semiconductors, jewelry, medical, aerospace industries.

2.3, Split fiber laser marking machine

The split fiber laser marking machine is known for its precision marking of 0.01mm on metal and non metal materials that is used on a wide range of applications. The split fiber laser consists of mainly four parts: fiber laser, galvanometer scanning system, computer control system and the work table.

The split fiber is compatible with softwares like photoshop, coreldraw and autocad. It is mostly applicable for marking in industries like: jewelry, electrical, electronic, automotive, food, pharmaceutical, etc. The air cooling system of the split fiber laser machine allows for maintenance of temperature when marking. The marking range is usually 175mm x 175mm.

The split fiber laser machine has a firm structure that needs to be placed on an elevated object or surface in order to get marking started. The compact size of the split fiber laser machine can fully meet the continuous needs of industrialized marking.

The split fiber laser consists of: the filed lens, galvanometer, laser source, upright column, power supply, control card.

The use of the split fiber laser machine cuts across various industries; hardware tools, electrical products, automotive parts, IT industry, jewelry industry, medical equipment, etc. Each of these industries need all their products to stand out among other similar products.

2.4, Stationary fiber laser marking machine

Stationary fiber laser marking machine is a type of laser marking system that adopts fiber laser beams to leave a permanent mark on the surface of a variety of metal and nonmetal materials that can be used in industrial manufacturing applications, small and large businesses. The stationary fiber laser marking machine has a total working lifespan of about 100,000 hours. It is mostly adopted for marking barcodes, QR codes, texts, images, serial numbers, etc on products for proper traceability and identification.

The stationary fiber laser does not have a direct contact with the material it is marking, this makes wear and tear impossible between material and laser.

The stationary fiber laser marking machines have simple structures and greatly reduce failure rates due to the fact that they do not require constant moving. The stationary fiber laser components are: the filed lens, galvanometer, laser source, control card, power system and the desktop itself.

The compact design makes it applicable for use in many industries. They are mostly used for large scale marking in automotive, plastic, electronics, semiconductors, jewelry, aerospace industries. Due to the fact that the stationary design can fit into the marking requirements of these industries that make use of metals and nonmetals, they are highly treasured.

2.5, When do you need a mini fiber laser marking machine

The mini fiber laser marking machine is the most sought after and fast selling when users have in mind that they need the fiber laser only to carry out their markings on materials as a hobby and not for profit making ventures. Although small businesses also adopt the mini fiber laser marking machine because of its outstanding features. The mini fiber laser marking machine can work on various materials including, paper, wood, plastic, aluminium, gold, silver, stainless steel, copper, etc.

First thing to note about the mini fiber laser marking machine is that it is small that it can fit into any space provided there is enough air in circulation. The engraving area is 12 by 8 inches (300 x 200mm)

The mini fiber laser marking machine also comes with an inbuilt computer that contains professional softwares such as PHOTOSHOP, AUTOCAD and CORELDRAW needed for marking on products. These softwares are professional English softwares, hence, users do not have to worry about the language of software. Files such as BMP, JPG, JPEG, WMF, EMF and PLT are all supported with the software.

Due to the laser’s compact size, marking is done ten times faster than the regular laser.

The fact that the mini fiber laser marking machine is affordable does not make it less efficient. Which is why it is better used for its high level of precision and high speed. Marks made on products are permanent, marks made do not fade.

This is the fiber laser that we can refer to as “Do it yourself”. The operation and use is very simple and lasts a very long time.

If you are looking at different degrees of marking and engraving on your material (surface laser marking or deep laser engraving), the mini fiber laser marking machine is capable of doing it.

The compact size of the mini fiber laser marking machine takes very little space in any production industry, hence, more space is saved. The mini fiber laser machine has a dynamic stability that makes maintenance very easy, there are no complicated machine parts rigorous cleaning or replacing .

The mini fiber laser marking machine is applicable for marking serial numbers, barcodes, texts, images, etc, for industries such as; medicine, telecommunications, aerospace, jewelry and other industries that make use of metals and nonmetals.

Chapter 3: Fiber Laser Marking Machine Application: Marking and Engraving of Various Materials

3.1, How the mini fiber laser marking machine works

Laser marking is the process of making products made of certain materials to distinguish them from others products and also make them easily traceable. Marking can be done with the mini fiber laser marking machine, which contains a laser technology. In laser marking, the laser beam hits the surface of the material, and its energy creates a reaction that leaves a permanent mark. When the beam interacts with the surface material, it alters the material’s property and appearance. The concentrated beam targets only a specified area, allowing the mini fiber laser marking machine to create precise, high quality, high contrast marks that are easy to read or scan on any surface.

Mini laser marking can be done in three methods, they include:

- Annealing: In the annealing method, the laser beam is defocused which allows the introduction of low heat on the material. This heat output leads to change in the structure of the metal, resulting in recolouring of the metal. The surface is not damaged, it remains smooth and clean. The temperature of marking can determine the shade of blackness.

- Engraving: During engraving, more energy is required more than annealing. The energy increase leads to vapourization of the material and total change of the surface. Inscriptions and markings are permanent and abrasion resistant.

- Removing: In the case of coated metals such as, anodized aluminium, the top layer is removed by laser processing.

How the mini fiber laser marking machine works:

The mini fiber laser machine works by using a focused beam of light to mark the surface of a material. When the beam interacts with the metal’s surface, it alters the metal’s properties and appearance. This concentrated beam targets only a specified area, allowing the mini laser marking machine to create precise, high quality, high-contrast marks that are easy to read or scan on virtually any surface. This feature makes laser marking ideal for industrial applications where accuracy and permanency are desired.

3.2, Mini fiber laser marking machine for metal

Laser applications in metal marking are typically used for marking products for the purpose of traceability. These applications can be found in the electrical and electronics industry, mechanical engineering and manufacturing tools, metal processing, automotive industry, etc. The laser marking or annealing marking is a common type of marking that does not affect the surface of metal.

No part of the metal is removed during the annealing marking. By heating the metal, however, a colour change is achieved. For example, the colour of the stainless steel changes at temperatures between 200°C and 300°C. Different colours can be achieved with different temperatures. The goal is to achieve a perfect black. Perfect black markings are possible on stainless steel and titanium, but not on other metals.

3.2.1. Mini laser marking and engraving on stainless steel

To mark on stainless steel, the mini laser marking machine is used to anneal on the surface. Laser annealing is the marking process optimized for stainless steel. The mini laser marking machine provides permanent marking without affecting the protective layer (i.e. chromium oxide). Annealing occurs when the chemical modifies the steel located under the chromium oxide layer. To do so, the surface is heated until it melts temporarily. During the short time span, oxygen travels below the surface. This creates the desired mark on the surface.During the annealing process, no material is removed, which means there is no ablation.

3.2.2. Mini laser marking and engraving on aluminum

The mini laser marking machine with relatively high pulse duration can engrave the anodised layer of aluminum well. Depending on the color of the layer, this results in a good contrast and a nice, bright engraving. However, this contrast is hardly visible on silver or natural anodised aluminium. Laser engraving aluminium has become popular due to the speed, quality of the mark produced, reliability, low-cost and pre-fabrication options available through the software. The mini fiber laser marking machine is used to mark text, graphics, barcodes, 2D, UID, matrix, QR codes and much more on any part of aluminum in various industries that makes use of aluminum.

3.2.3. Mini laser marking and engraving on gold

Mini laser marking machines can be used to mark and engrave on gold. Jewelry production companies and bullion companies make use of the mini laser marking machine to make permanent inscriptions on gold surfaces. Logos, alphanumeric texts, images, are all marked or engraved on wristwatches, earrings, bracelets, pendants, etc. These marks are created to add personalized touch to jewelry items. Markings and engravings are done on bullion to identify the size, composition and the jewelry company that produced the bullion.

By using the mini fiber laser with the high energy, the heat is quickly absorbed by the material. Despite the use of a high energy laser, the parameters of the fiber laser can be adjusted for the delicate or thin gold items.

3.2.4. Mini laser marking and engraving on silver

Laser marking and engraving on silver is totally indispensable. Silver items without marking or engraving do not give a great appeal. Mini laser marking machines are of important priority in the jewelry making business and other industries that make use of silver in production. The mini laser engraving machine makes high precision engravings on the silver material. There is no direct contact with the material when the mini fiber laser marking machine is engraving either barcodes, images or texts on the material surface. Annealing is the process used to achieve marking or engraving on sterling silver without any material loss.

3.2.5. Mini laser marking and engraving on copper

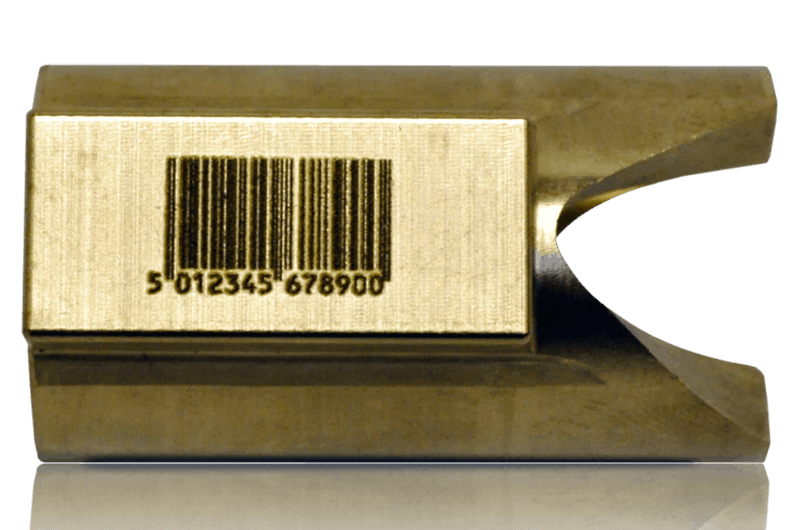

Copper is a soft, ductile, and malleable metal with a high thermal and electrical conductivity, making it ideal for laser engraving. The metal is widely used across various industries and it is used to make coins, electrical wires, cookwares, semiconductors, etc. All these industries make use of the mini laser marking machine to make high precision marks on their products at a very fast rate. Different logos, texts, barcodes are easily engraved on copper surfaces with a smooth finish.

3.2.6. Mini laser marking and engraving on plastic

The mini fiber laser marking machine can make permanent and high contrast marks on plastics as against the direct ink printing on plastic surfaces that can be easily removed by abrasion or solvents. Marking of plastics with the mini laser is accomplished through colour changes and/or surface restructuring. Four different types of mark can be distinguished namely foaming, engraving, engraving with colour change, and colour change only.

Foaming: As low laser intensifies on certain polymers Laser marking creates a thin walled foam structure, this appears a lighter colour from the bulk of the polymer.

Engraving: Localised increase in temperatures above the melting point of the material causes melting. Once the material is re-solidified, a modified surface structure occurs in the form of an etch.

Engraving with colour change: At relatively high rate laser intensities, a local evaporation of surface material causes a trench with ridges. As a result of carbonization, a colour change occurs.

Colour change: With Laser radiation of sufficient short wavelength, a dissociation of molecules results in a colour change; this is the most desired effect. Mark contrast can be enhanced using a limited amount of additives.

3.3, Mini fiber laser marking machine for Industry

The mini fiber laser marking machine is used across various industries. Most industries make use of stainless steel, gold, silver, copper, plastic, etc for production of electronic components, automotive parts, semiconductors, etc, and they need to be able to trace and identify their own products from other industries that make similar products. Hence, serial numbers, logos and barcodes are marked on their products.

3.3.1. Automotive laser marking

Automotive companies need to be able to trace their products from any part of the world. This is among the reasons they use alphanumeric character sequences, complex codes on their products for this purpose. The mini fiber laser marking machine is the ideal tool to reliably and quickly apply these codes and other contents to almost all materials used in the automotive industry while achieving a quality finish.

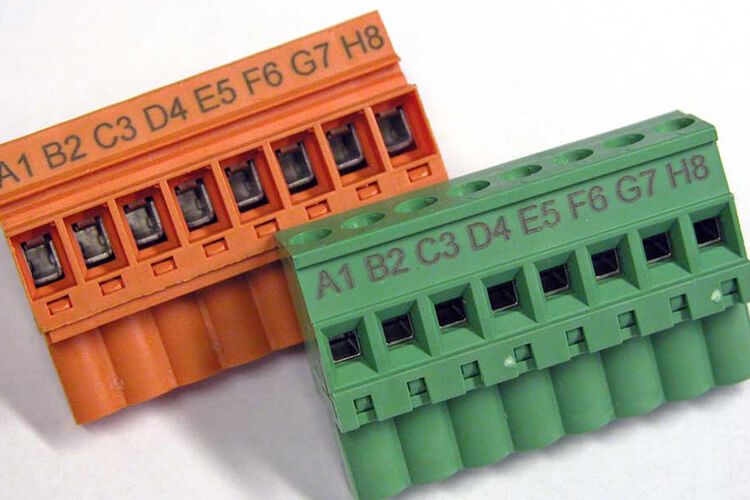

3.3.2. Electronic components marking

Electronic industries now use the mini fiber laser marking machine to mark electronic components as a standard process of achieving maximum quality and durability of information marked. Laser marking is suitable for marking complex codes, which needs to be permanent, readable and resistant to external agents. Laser marking provides an essential factor for mass production for an industry like the electronics industry.

3.3.3. Jewelry laser engraving

Inscriptions are made on jewelries with the mini laser engraving machines just to personalize them. Company logos, names, dates, photos, etc can be engraved on different jewelry pieces.

3.3.4. Watch laser engraving

Gold and silver wrist watch parts are engraved with different texts, part numbers, serial numbers and logos. The great advantage of the mini laser engraving machine here is that high precision marks can be carried out efficiently and quickly on the smallest parts of wrist watches.

3.3.5 Barcode laser marking

Barcodes are used by virtually all industries for the purpose of traceability. Barcodes contain information regarding the production data, batch numbers, etc. Barcodes are usually marked at a high speed and precision with a mini fiber laser marking machine.

3.3.6. QR code laser engraving

QR codes contain data about a particular product and they can be scanned anywhere and anytime to get information about that product. Fiber laser engraving machines are used by several industries to engrave high precision and permanent QR codes on their products.

3.3.7. Nameplate engraving

Mini Laser engraving machine through its non contact marking process makes clean and permanent marks on nameplates. Date codes, serial numbers, 2D barcodes, or any sequence of numbers and characters. Laser engraving machines are equipped with a nameplate shuttle system that allows for complete automated nameplate marking.

Chapter 4: How to Choose A Suitable Fiber Laser Marking Machine

4.1, Power

Fiber laser marking machines adopt 20w, 30w or 50w as the output power of the laser source. A good or bad laser is not decided by output power, but by the brand of the laser source.

4.2, Marked area

Marking areas allow only 2D marking. On the other hand, 3-axis control laser markers provide a concept of volume or “space”, because the focal point is variable. Therefore, for 3-axis control laser markers, the expression “space” is used, instead of “area”. For example, 120 x120mm, 110 x 110mm, 70 x 70 mm, etc.

4.3, Marking depth

Marking depth refers to how deep you want engravings to appear on materials. Laser marking discolours the surface of the material, laser engraving removes a little portion of the material in order to get a little deep to reveal an image or text. Different laser marking machines are able to achieve different levels of depth when engraving.

Marking and engraving depth varies according to metal types. Let us examine the marking depths of our mini marking machine on different metal surfaces.

Stainless steel: Markings appear very shallow on the surface with the 20w power. While the 30w and 50w power marks at a depth of 0.2mm to 0.25mm respectively.

Aluminum: Markings appear only on aluminum surfaces with the 20w power. While the 30w and 50w power marks 0.3mm to 0.35mm depth respectively.

Gold: Markings appear on gold surfaces with 20w power, while the 30w and 50w power marks 0.6 to 0.8mm respectively.

Silver: Markings appear on silver surfaces with the 20w power, while the 30w and 50w power marks at a depth of 0.65mm to 0.9mm respectively.

Copper: With the 20w power, marks appear on the copper surface, while the 30w and 50w makes a depth of 0.65mm to 0.9mm respectively.

4.4, Marking material

You also need to take into account the material that you have to engrave since the surface of the material plays an important role in the selection of the laser. In case you want to engrave hard material like metal like aluminum or stainless steel then you will need to choose a higher-powered machine.

4.5, Price

Your budget for the purchase is going to determine the kind of machine you will buy. Though the price of the laser engraving machine isn’t necessarily going to dictate the quality of it, budget is one of the things to be considered while making a purchase decision. Laser marking machine prices are often determined by the power requirement of the laser machine. Laser machines that require less power are not as expensive as the ones that require more power for marking.

4.6, Maintenance costs

Maintenance is another crucial thing to consider while buying a laser engraving machine. Find out how frequently the maintenance is required for the machine and whether you can do it yourself or need to hire someone else to do it for you. Determining whether the device is easy to maintain or repair is complicated, resulting in a lot of downtimes. If it is difficult to maintain, your company might need to hire a technician to do the maintenance activity, which can result in additional cost. Thus, look for a machine that is easy to maintain and repair.

4.7, Durability

Fiber laser machines can withstand a little more wear and tear than other models. A gas laser must be readjusted if it shakes or is misaligned. Fiber lasers, on the other hand, have no moving parts. So, there’s no need to worry about breaking a piece every time there is a misstep. Laser machine users do not have to act as delicately while operating this machinery. Since there are little to no moving parts, mini fiber laser machines are also safer for workers to use. Their exceptional durability is one reason supervisors should invest in these machines.

4.8, Marking needs

Choose your fiber laser marking machine according to your marking needs. In this age of efficiency, we usually need metal marking machines that can automate marking or integrated devices to do batch marking on the production line and software that can automatically replace content such as serial number auto increment. If you have such a demand, you need to choose high output power machines such as 20w, 30w, 50w fiber lasers. The high power laser machine can be a more stable actual laser output and has a longer working life.

4.9, Replacement parts

Another factor to consider is whether the replacement parts are readily available when the laser engraving parts need to be replaced. Regardless of which device you buy, it is going to need some replacements, for instance the lens. Thus, it becomes vital to know whether the replacement parts of the laser engraving machine are available with ease, or you will have to wait for months before getting them.

Chapter 5: How to Configure Fiber Laser Marking to the Production Line

5.1 Application of laser marking equipment in production line

Laser marking is often used by industries for traceability, quality control ( being able to identify counterfeit products that may pose a threat to a company’s image) , identification and process improvement. For the purpose of identification, buyers can scan barcodes to know the authenticity of the products they are buying. For traceability purposes, it is possible for manufacturers to track and trace product production from the beginning to the end. For quality control and process improvement, it is possible to store important information specific to each part in a database. Identification can be in forms of QR codes, data matrix codes, logos, and alphanumeric serial numbers.

Industries make use of the laser marking machine due to the benefits, such as: permanent and readable marks on their products, high speed of marking, high contrast marking, no contact between the laser and material which means no wear or tear, no consumables is requires, can be used to mark many production materials.

Using the fiber laser marking machine is applicable to industries such as aerospace, automotive, jewelry, medical, semiconductors, etc, that make use of stainless steel, aluminium, silver, gold; and nonmetals like engineering plastic and hard plastic.

- Aerospace- The aerospace is a large industry that incorporates commercial lines, military jets, private jets and transportation jets. This industry clearly needs fast and efficient means of production. It is no surprise therefore that the use of fiber lasers is widespread within the aerospace industry. The aerospace industry makes use of many metal parts, marking these parts need to be fast and efficient in order to keep up with fast production demands.

- Automotive industry- The automotive industry bears many similarities with the aerospace industry, in the way the production line works. The automotive industry is about high production and high efficiency. Fiber laser machines are used to accurately mark various automobile components at a high precision and efficient rate. The automotive industry also produces military vehicles such as tanks. Barcodes, serial numbers, etc are marked on engines, nuts and bolts, wheels, etc.

- Jewelry industry- The jewelry industry is also a sizable industry that produces billion dollars worth of jewelries annually. The fiber laser marking machine brings out the creativity in every jeweler as various designs can be engraved on jewelry items such as necklaces, wristwatches, tags, weddings and engagement rings, etc. High precision and permanent engravings are done on jewelries to make them last a lifetime.

- Medical industry- The medical industry uses the fiber laser machine to create safe, reliable, and efficient medical tools, instruments and pieces of equipment. Some of the medical equipment that can be marked are: knives, bone saws, skull drills, insulin dispensers, needles, stents or bone connectors, crutches, etc.

- Semiconductors- The semiconductor industry bears similarities with the electronics industry. The fiber laser marking machines are widely used in this industry because of the benefit that they can mark very small parts and they will not cause any damage to the rest of the surrounding area of the semiconductor. Semiconductors, just like electronics, are used in many of our everyday products, so it’s crucial that these are created safely and reliably.

5.2, We can provide the entire production line solution

Here at Alldo Tech, we specialise in the manufacture of the fast rising laser marking and engraving technology that serves as the forefront of production. Whether you require a solution that offers a more profitable result to existing challenges with your machine or you are looking to create a new project, our fiber lasers are able to adapt to a wide range of applications.

We understand that time is money and there are tight deadlines that have to be met. We provide you with a timely and fast marking for all your products. Fast marking time of our machine does not compromise the marking high standard, because we understand that substandard quality in finished products can lead to a downfall in production.

Even after the purchase of our fiber laser, we provide a system of maintenance and support for you, in order to help you ensure that your laser machine lasts a very long time.

Fiber lasers are accurate, reliable, highly customizable, and very versatile. They can be easily automated and integrated into most production processes. With a little creative thinking, your manufacturing operations can also be enhanced with the addition of fiber lasers.

Get In Touch